Gas density relay with online self-calibration function and calibration method thereof

A gas density, relay technology, applied in the field of electric power, can solve problems such as hazards, potential safety hazards, flashovers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

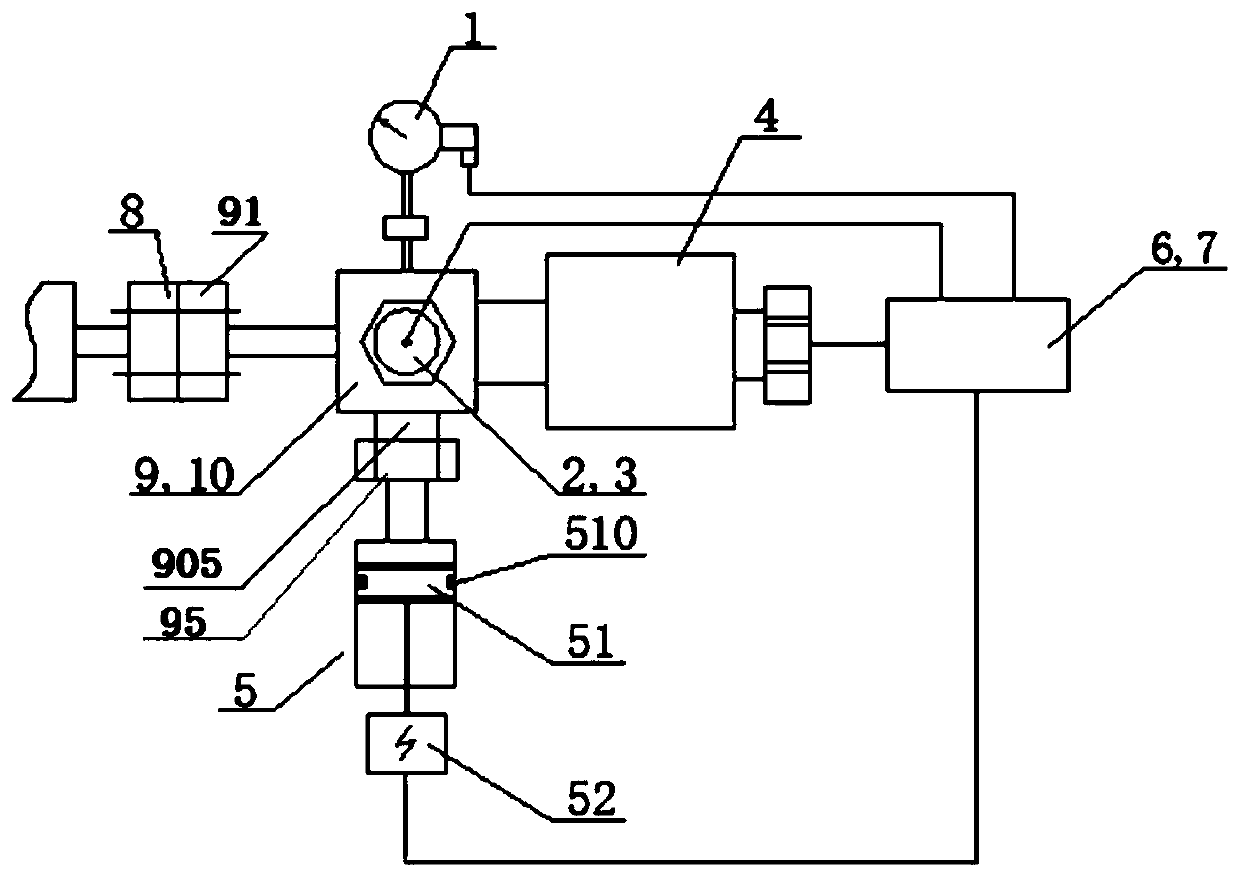

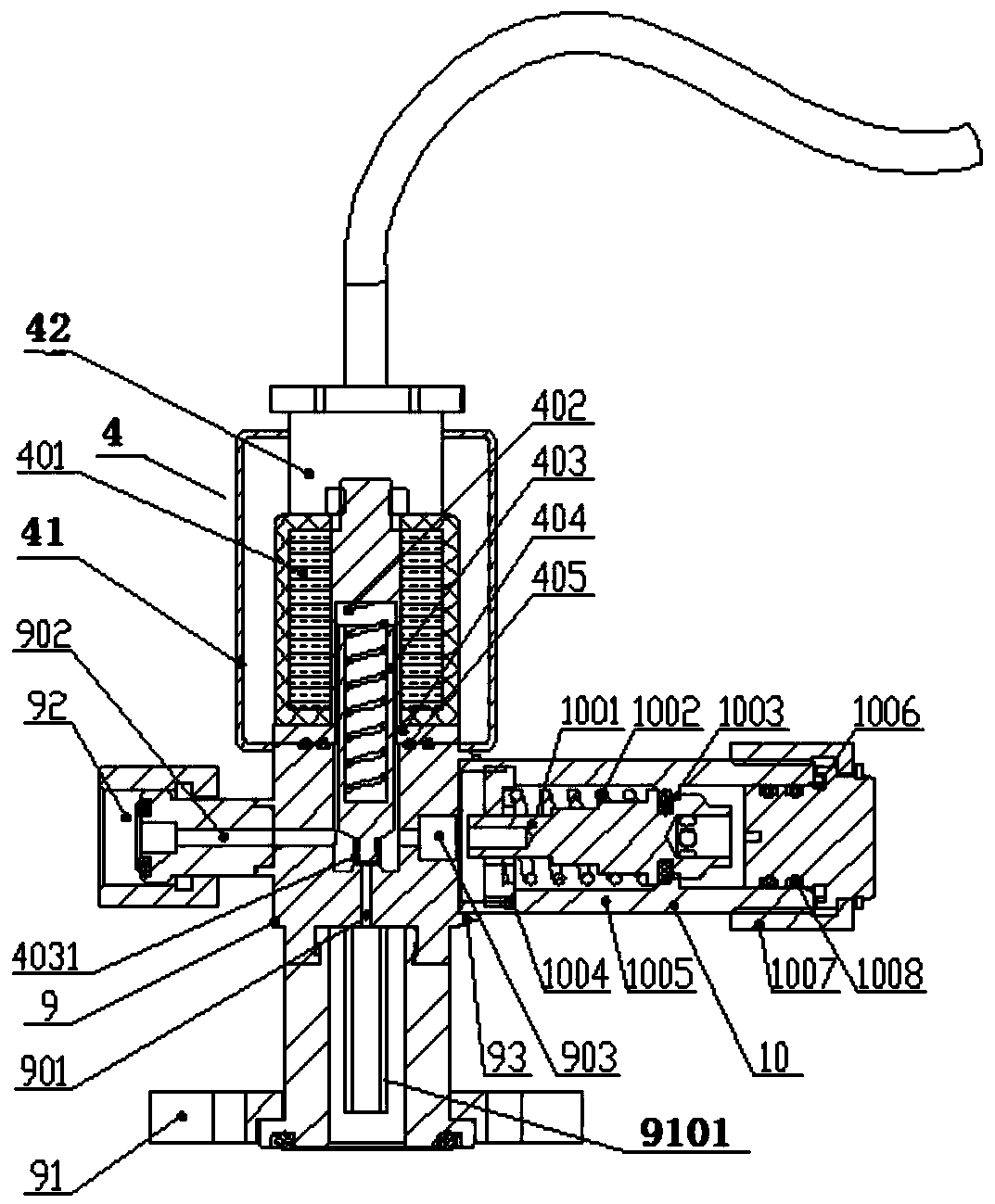

[0138] like figure 1 As shown, the first embodiment of the present invention provides a gas density relay or a gas density monitoring device with an online self-verification function, including: a gas density relay body 1, a pressure sensor 2, a temperature sensor 3, a valve 4, and a pressure regulating mechanism 5. On-line verification contact signal sampling unit 6, intelligent control unit 7, multi-way joint 9 and air supply interface 10. The gas density relay body 1 , valve 4 , pressure sensor 2 , pressure regulating mechanism 5 and gas supply interface 10 are arranged on the multi-way joint 9 . Specifically, see figure 2 , the multi-way joint is provided with a third interface 91, and the third interface 91 is provided with a connecting portion that is docked with the electrical equipment 8, and the valve 4 is partially or completely embedded in the multi-way joint 9 , that is, the valve 4 and the multi-way joint 9 are integrally designed. The multi-way joint 9 includ...

Embodiment 2

[0163] like Figure 4 As shown, a gas density relay or a gas density monitoring device with an online self-verification function provided by Embodiment 2 of the present invention includes: a gas density relay body 1, a pressure sensor 2, a temperature sensor 3, a valve 4, and a pressure regulating mechanism 5. On-line verification contact signal sampling unit 6, intelligent control unit 7, multi-way joint 9, air supply interface 10. The multi-way joint is provided with a third interface, and the third interface is provided with a connecting portion docked with the electrical equipment 8, and the valve 4 is partly (or completely) embedded in the multi-way joint 9, That is, the valve 4 and the multi-way joint 9 are integrally designed. The gas density relay body 1 is installed on the multi-way joint 9; the pressure sensor 2, the temperature sensor 3, the online verification contact signal sampling unit 6 and the intelligent control unit 7 are arranged on the gas density relay b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com