A kind of polyurethane based on polyetherester polyol and its preparation method and application

A technology of polyether ester polyol and polyurethane, which is applied in polyurea/polyurethane coatings, biocide-containing paints, coatings, etc., can solve the problem of short antifouling period, failure to achieve antifouling effect, and antifouling of marine equipment Poor protection effect and other problems, to achieve the effect of good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

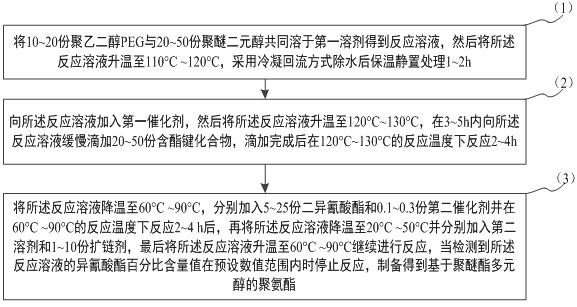

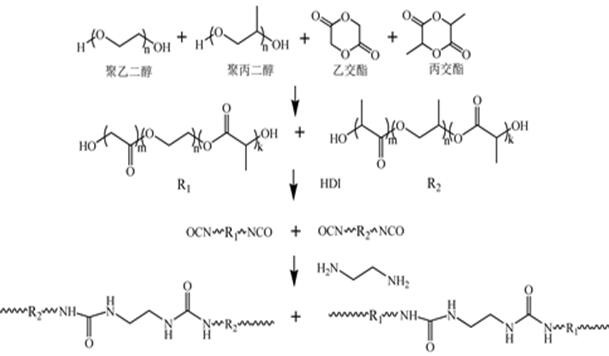

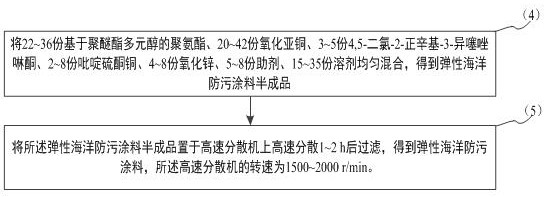

[0032] figure 1 It is the method flowchart of the preparation method of the polyurethane based on polyether ester polyol shown according to an exemplary embodiment, as figure 1 Shown, the preparation method of the polyurethane based on polyether ester polyol comprises:

[0033] Step (1): Dissolve 10-20 parts of polyethylene glycol PEG and 20-50 parts of polyether diol in the first solvent to obtain a reaction solution, and then raise the temperature of the reaction solution to 110°C~120°C , use the condensing reflux method to remove water and then keep it warm for 1~2h.

[0034] The average molecular weight of the polyethylene glycol PEG is 100-500, and the first solvent includes at least one of xylene or toluene.

[0035] In the present invention, polyethylene glycol PEG and polyether diol are used as initiators.

[0036] In a preferred embodiment, the polyether diol includes at least one of polytetrahydrofuran ether polyol PTMG or polypropylene oxide polyol PPG.

[0037]...

Embodiment 1

[0059] (1) Put 20 PEG 400 with 30 PPG 1000 Dissolved together in xylene to obtain a reaction solution, then the reaction solution was heated up to 110 ° C, and the water was removed by condensation and reflux, and then kept for 1 h.

[0060] (2) Add stannous octoate to the reaction solution, then raise the temperature of the reaction solution to 120°C, slowly add 20 parts of glycolide and 25 parts of lactide dropwise to the reaction solution within 3 hours, and the dropwise addition is completed Then react at a reaction temperature of 120° C. for 2 h to prepare polyether ester polyol.

[0061] (3) Cool the reaction solution to 60°C, add 13 parts of HDI and 0.2 parts of dibutyltin dilaurate respectively and react at a reaction temperature of 80°C for 2 h, then cool the reaction solution to 20 °C and add DMF and 4.8 parts of ethylenediamine respectively, finally the reaction solution is warmed up to 65 °C to continue the reaction, when the isocyanate percentage content value o...

Embodiment 2

[0066] (1) Mix 10 parts of polyethylene glycol PEG 200 with 30 copies of PTMG 2000 Dissolved together in xylene to obtain a reaction solution, and then the reaction solution was heated to 115 ° C, and the water was removed by condensation and reflux, and then kept for 1.5 hours.

[0067] (2) Add zinc oxide to the reaction solution, then raise the temperature of the reaction solution to 125°C, slowly add 15 parts of caprolactone and 10 parts of valerolactone dropwise to the reaction solution within 4 hours, after the addition is completed, React 3h under the reaction temperature of 125 ℃, prepare polyether ester polyol.

[0068] (3) Cool down the reaction solution to 60°C, add 22 parts of TDI and 0.2 part of bismuth laurate respectively and react at a reaction temperature of 60°C for 3 h, then cool down the reaction solution to 50°C And add DMSO and 5.8 parts of butanediol respectively, finally described reaction solution is warming up to 85 DEG C and continues to react, stop...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com