Bottle unscrambler

A bottle unscrambler and bottle body technology, which is applied in the field of bottle unscramblers, can solve the problem that the front film roll does not correspond to the position of the bottle, and achieve the effect of avoiding time-consuming, labor-intensive and error-prone, and consistent placement order

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

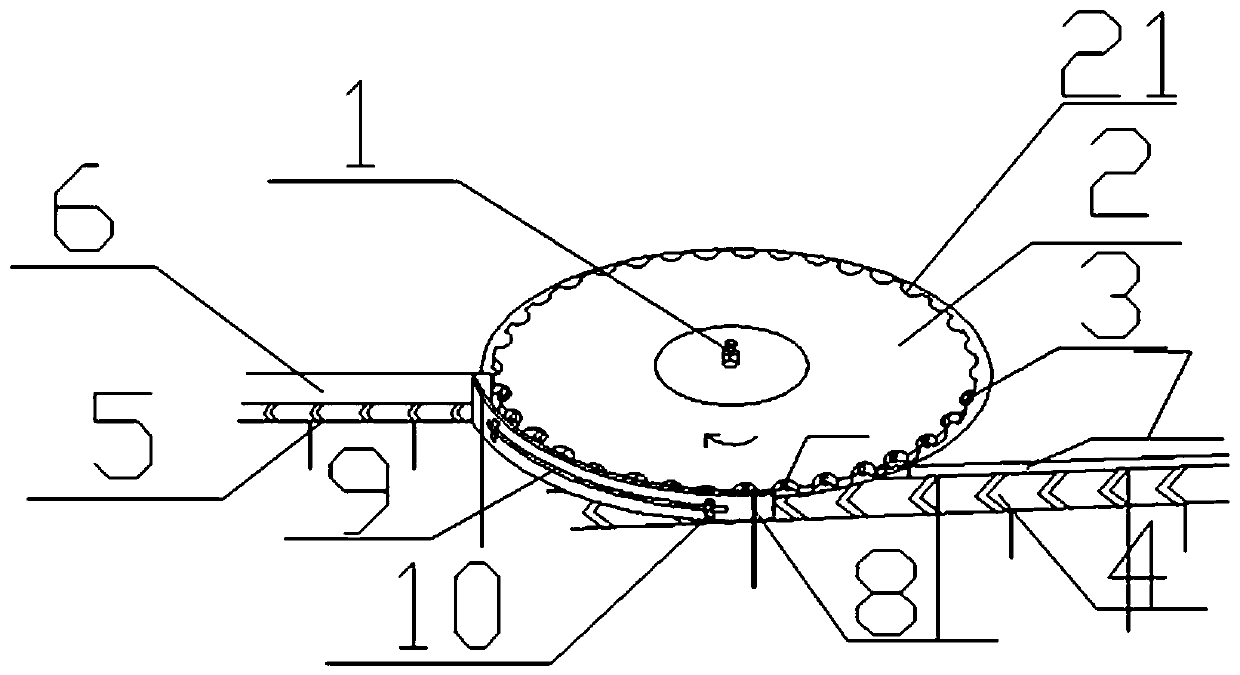

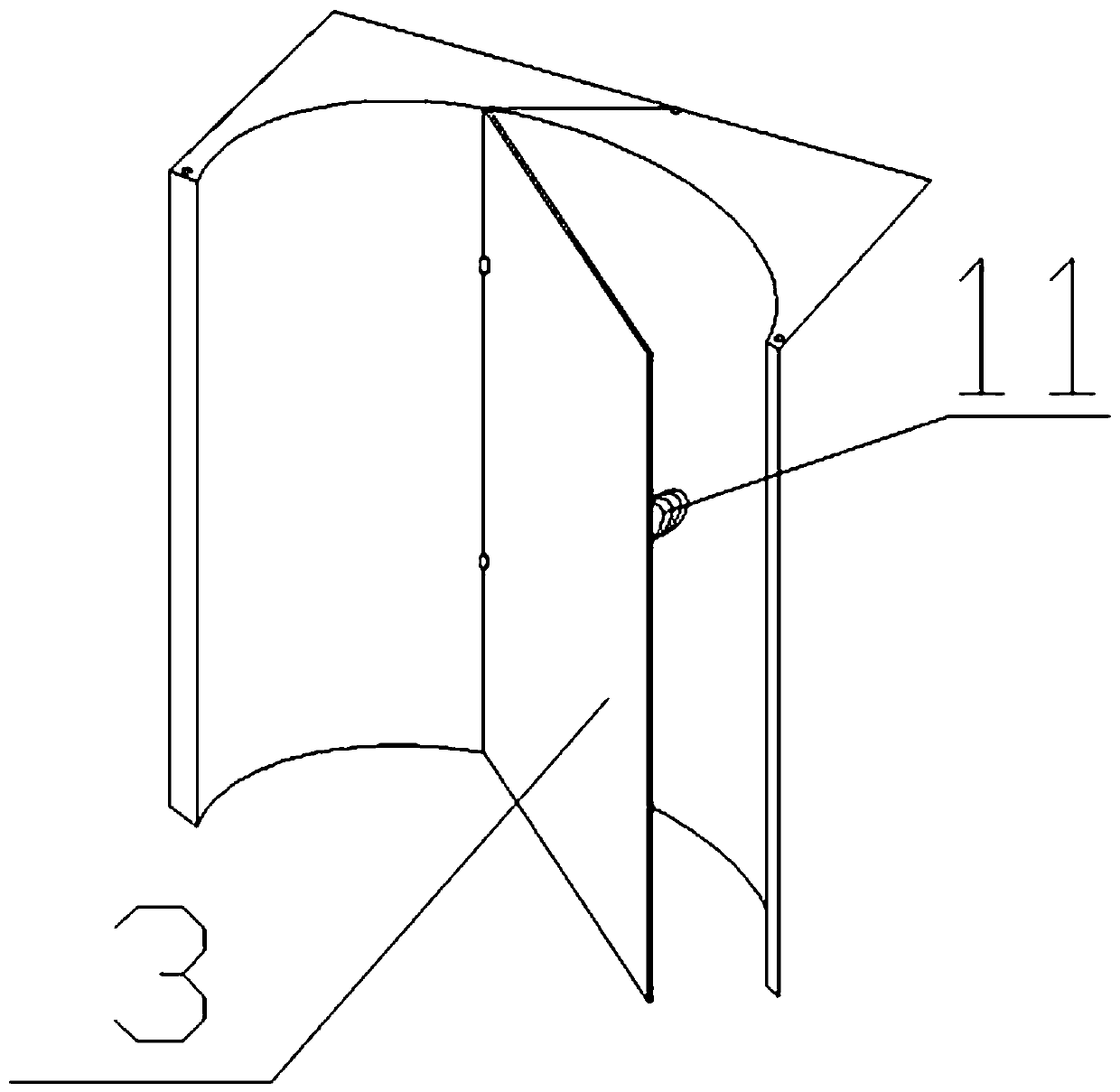

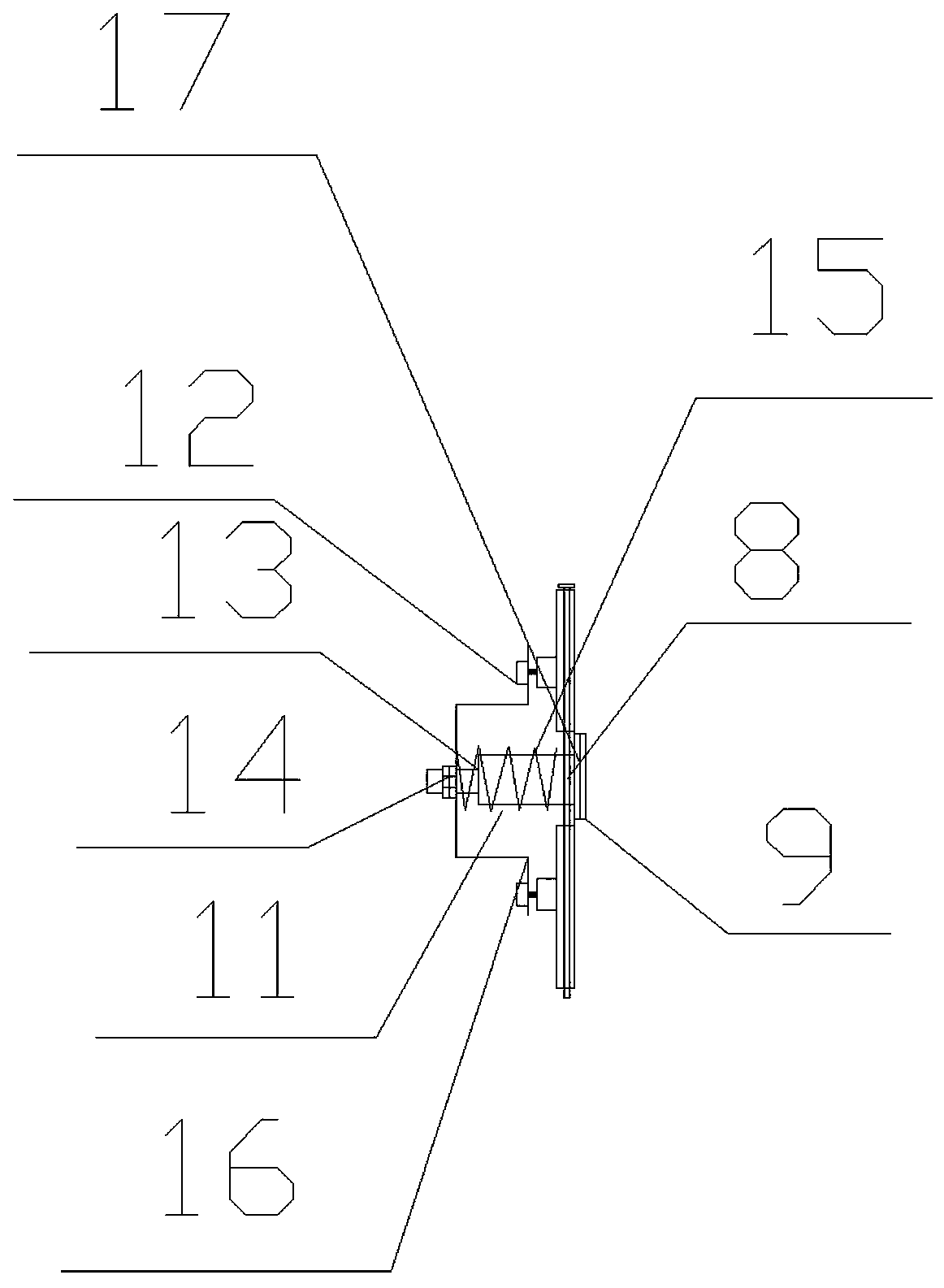

[0019] A bottle unscrambler, as shown in Figures 1, 2, and 3, includes a rotating motor 1 and a turntable 2. The motor 1 drives the turntable 2 to rotate, and the outer edge of the turntable 2 is evenly provided with circular arc-shaped fixing positions 21 around the circumference. The clamping position 21 is matched with the body of the bottle, and the fixed clamping position 21 is provided with an engaging spring 3, which is connected to the spring I11, one end of the spring I11 is welded to the middle of one side of the engaging elastic 3, and the other end is welded Inside the fixed card position 21 , one side of the engaging elastic piece 3 is hinged to the middle of the fixed card position 21 , and the said engaging elastic piece 3 can elastically move inside the fixed card position 21 . The position and the size of the engaging shrapnel 3 depend on the height and the size of the bottle groove. The front and rear of the bottle unscrambler are respectively connected to co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com