A jig for removing air bubbles in glass crevices

A technology of cracks and bubbles, applied in the field of fixtures with bubbles between two glasses, can solve the problems of time-consuming and labor-intensive, uneven force application, etc., and achieve the effect of avoiding time-consuming, labor-intensive and damage avoidance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

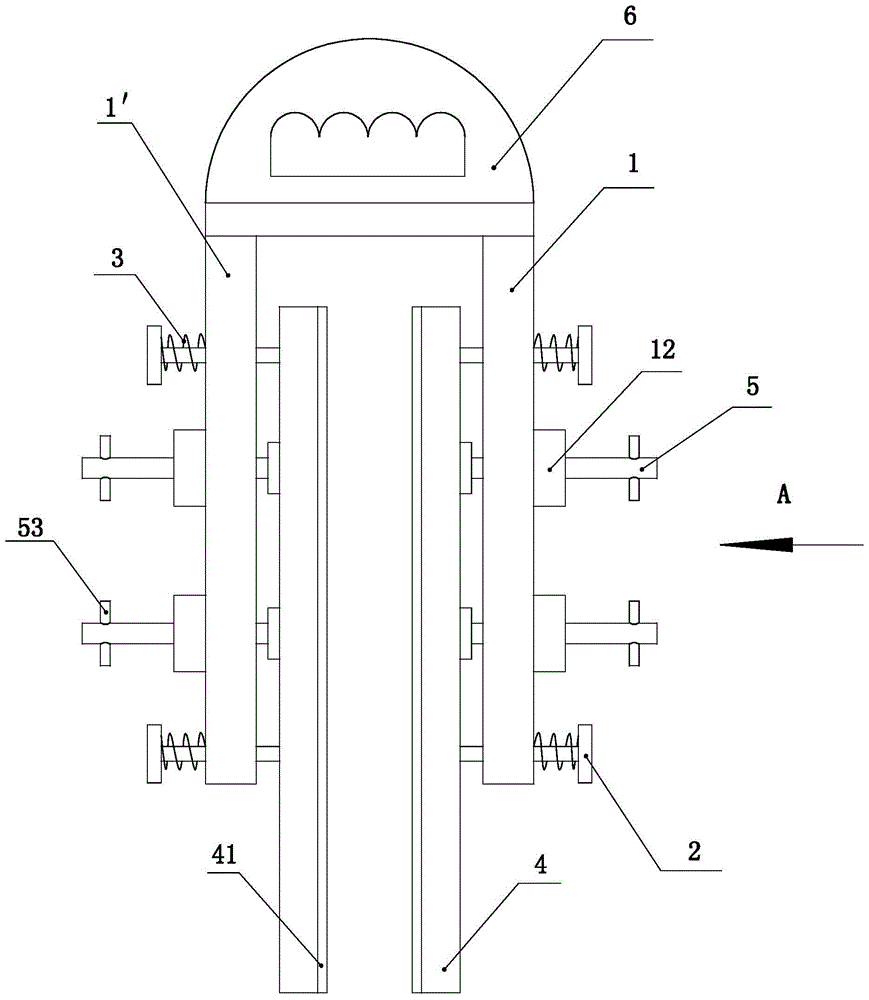

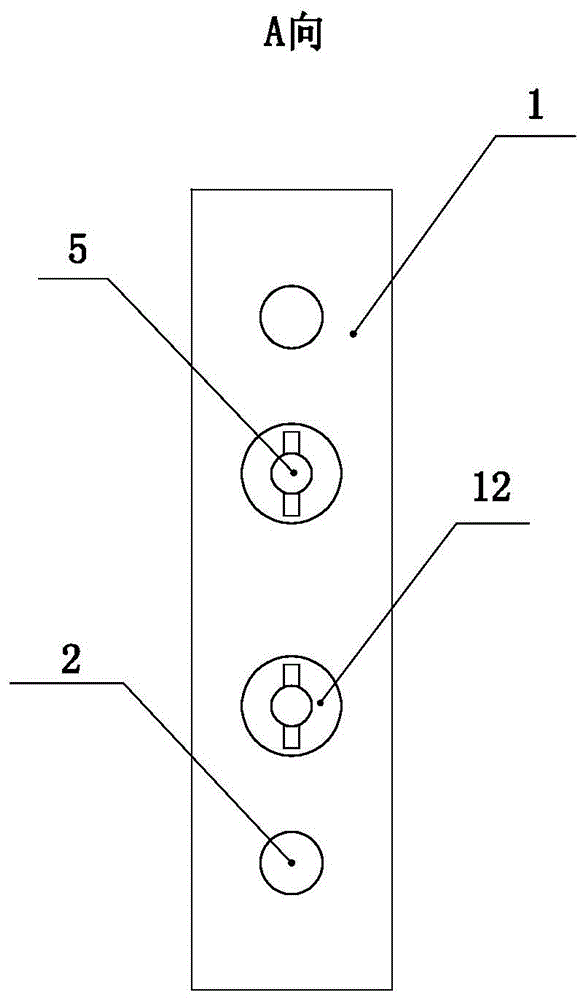

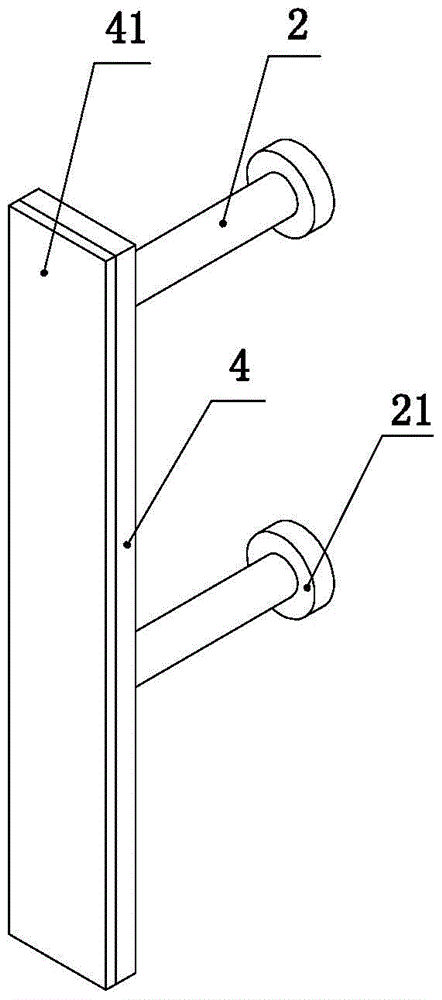

[0022] Such as Figure 1 to Figure 6 As shown, the present invention includes a base plate 1 (1'), a movable rod 2, a spring 3, a splint 4, a rubber pad 41, a push rod 5 and a handle 6, and the present invention will be described below in conjunction with the accompanying drawings.

[0023] Such as Image 6 As shown, the substrate 1 ( 1 ′) is a rectangular metal or plastic part, and the length of the substrate is much larger than the width and thickness of the substrate. Two ends of the base plate are respectively provided with a through hole 11, and two protrusions 12 are arranged on the base plate between the two through holes. The protrusions are circular metal parts, and internal threads 121 are provided on the protrusions. The boss can be welded on the base plate, and can also be integrally formed with the base plate. The substrates are two oppositely arranged, and the two substrates are connected together by a handle 6, such as figure 1 As shown, the handle is arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com