An integrated hydrotreating and steam pyrolysis process for the direct processing of a crude oil to produce olefinic and aromatic petrochemicals

A technology for hydrotreating, crude oil, applied in the field of steam pyrolysis, which can solve the problems of expensive process steps and limited availability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below with reference to the accompanying drawings.

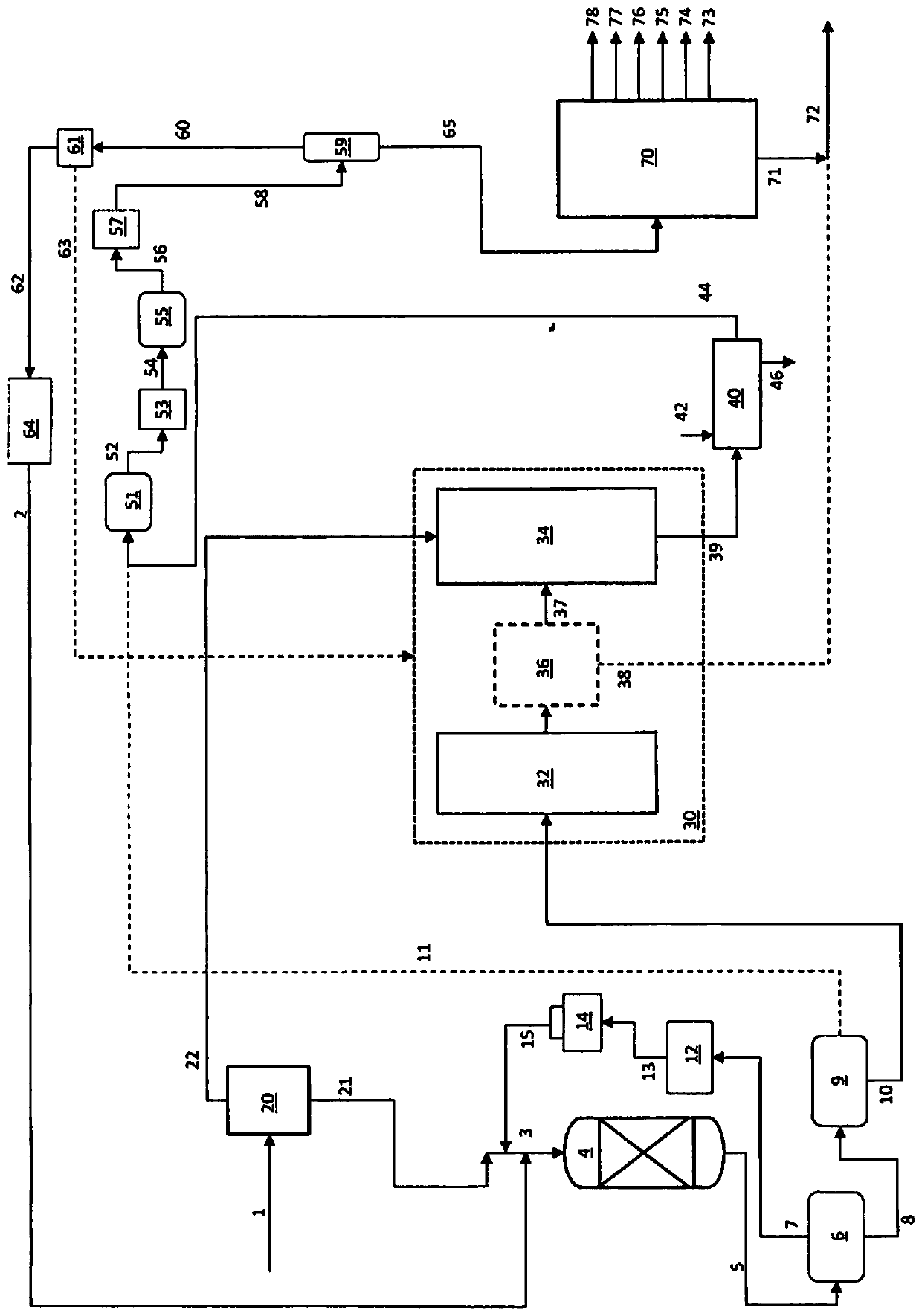

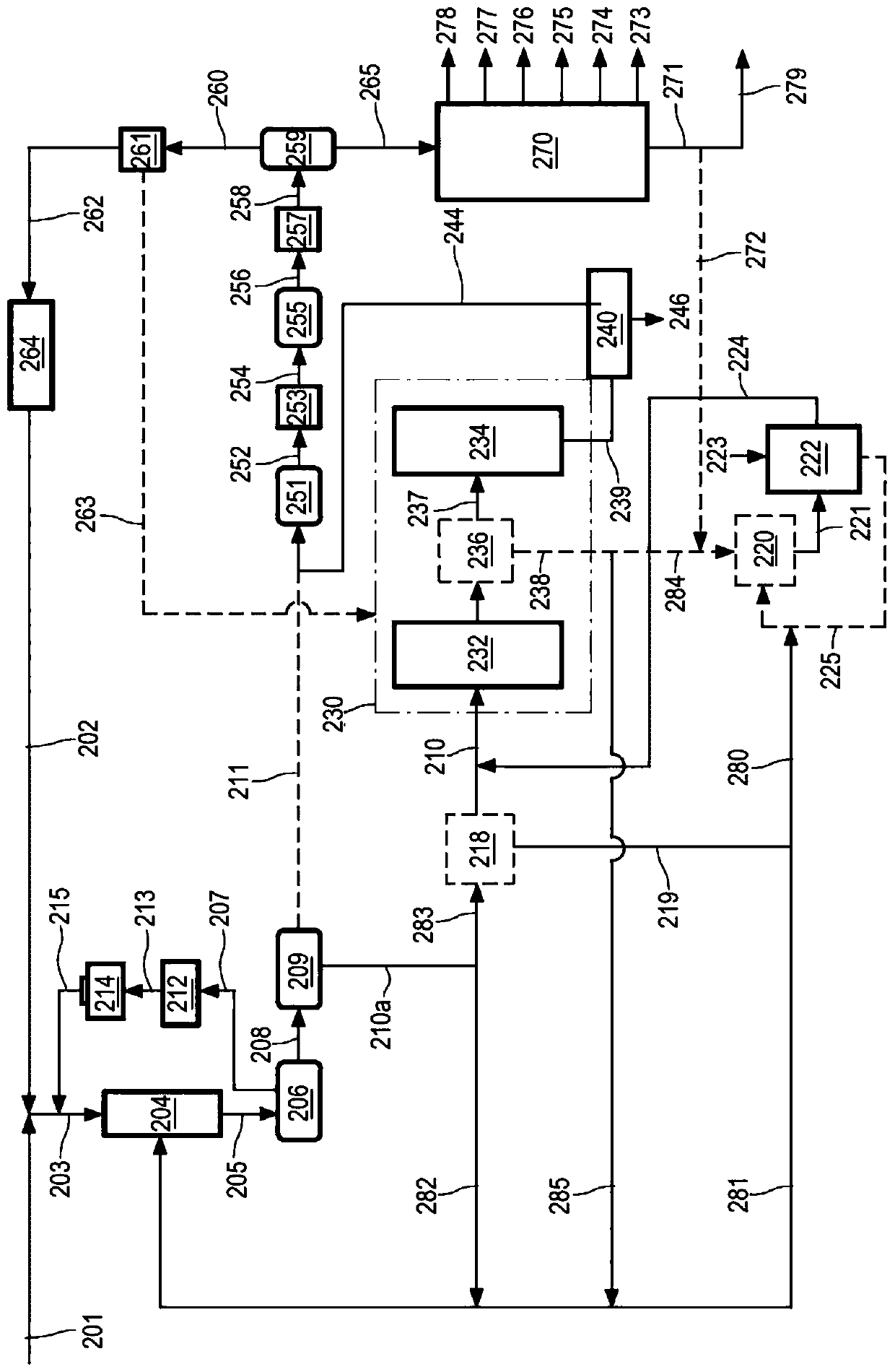

[0037] figure 1 A process flow diagram comprising a method and system for integrated hydroprocessing including hydrogen redistribution and steam pyrolysis according to Embodiment 1 above is shown in . The integrated system generally includes an initial feed separation zone 20, a selective catalytic hydroprocessing zone, a steam pyrolysis zone 30, and a product separation zone.

[0038] Typically, the crude feed is flashed whereby the lighter fractions (having a boiling point in the range containing minimal hydrocarbons requiring further cracking and containing easily liberated hydrogen, e.g. up to about 185°C) are passed directly to steam pyrolysis zone, and only the essential fractions (ie, fractions with a hydrogen content below a predetermined level) are hydrotreated. This is advantageous because it provides increased hydrogen partial pressure in the hydro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com