An optimal control method for improving the reliability of the bypass heating operation of the unit

A technology of optimal control and reliability, applied in heating methods, heating systems, household heating, etc., can solve the problem of the lack of targeted research on the optimal control of reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

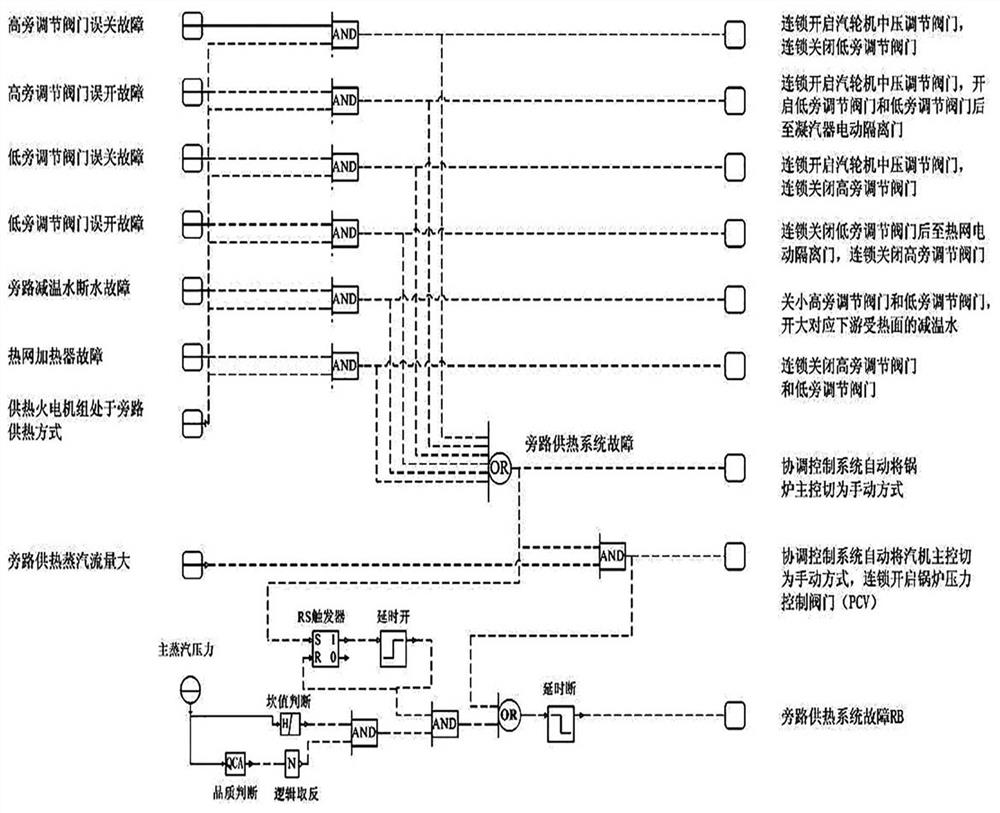

[0082] The present invention is an optimized control method for improving the reliability of unit bypass heating operation, such as image 3 as shown, image 3 Be the workflow block diagram of the present invention, comprise the steps:

[0083] Step 1: When the heating thermal power unit is in the bypass heating mode, judge the failure of the unit bypass heating system by configuring the control logic of the distributed control system DCS of the heating thermal power unit;

[0084] Step 2: Determine the steam flow rate of the bypass heating supply, and perform chain protection actions in combination with the failure of the bypass heating system of the unit to ensure the safe and stable operation of the unit;

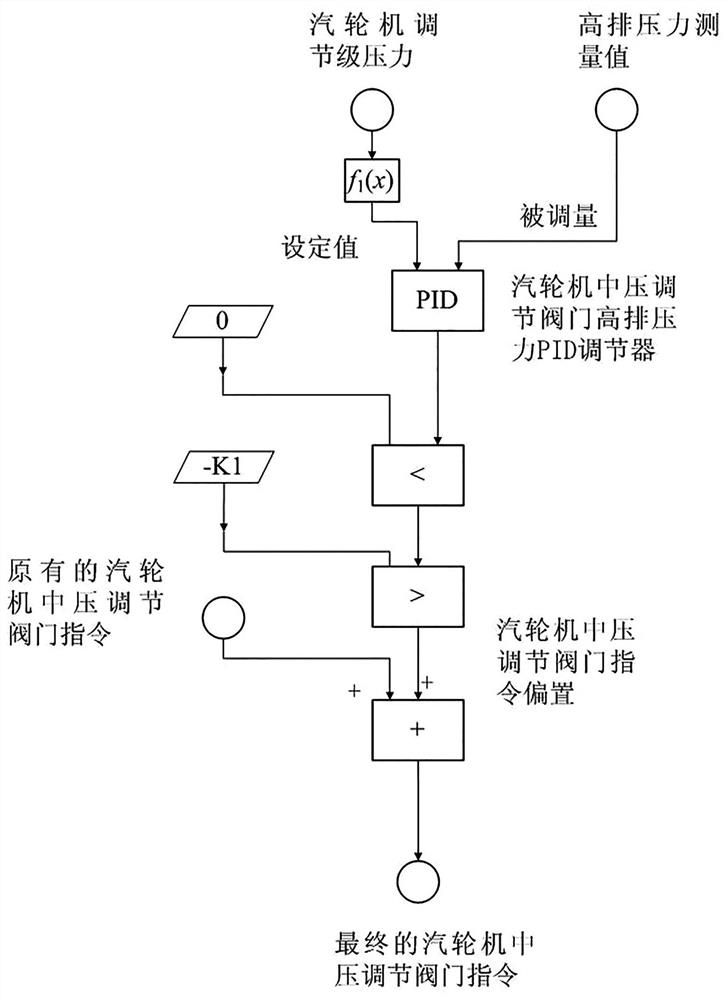

[0085] Step 3: Add automatic control logic to control the stability of the operating parameters of the unit bypass heating system;

[0086] Step 4: Query the historical operation data and design data of the DCS of the decentralized control system of thermal power units...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com