Base oil of cotton picker spindle lubricating grease

A cotton picker and lubricating grease technology, applied in the directions of lubricating compositions, base materials, petroleum industry, etc., can solve problems such as restricting the expansion of cotton scale and improving economic benefits, unable to meet the timely harvesting of cotton, affecting output and the like , to achieve the effect of good biodegradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The base oil of cotton picker spindle lubricating grease, in parts by mass, is obtained by mixing the following components uniformly according to the following ratio:

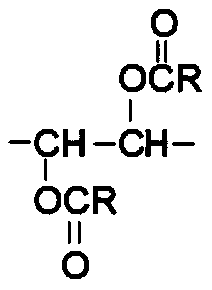

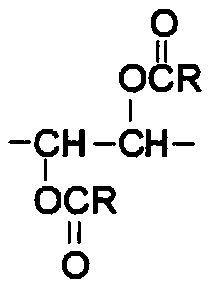

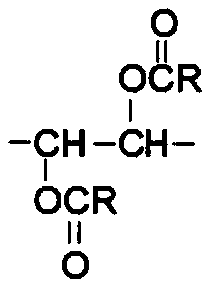

[0046] Include (where R is -CH 2 CH 2 CH(CH 2 CH 3 ) 2 ) structure and does not contain 5.0 parts of epoxy cottonseed oil, 35.0 parts of neopentyl glycol dioleate, 45.0 parts of isooctyl oleate and trihydroxy 15.0 parts of methyl propane oleate.

Embodiment 2

[0048]Spindle lubricating grease for cotton pickers, in parts by mass, is obtained by uniformly mixing the following components according to the following ratio:

[0049] 100.0 parts of base oil obtained in Example 1, 1.52 parts of 12-hydroxy lithium stearate fatty acid lithium soap, 0.38 part of lithium stearate soap, 3.0 parts of vehicle gear oil complex agent T4208 and 0.1 part of metal deactivator T551.

Embodiment 3

[0051] The base oil of cotton picker spindle lubricating grease, in parts by mass, is obtained by mixing the following components uniformly according to the following ratio:

[0052] Include (where R is -CH 2 CH 2 CH(CH 2 CH 3 ) 2 ) structure and 20.0 parts of esterified modified epoxy soybean oil without epoxy ring characteristic absorption peak and hydroxyl characteristic absorption peak, 20.0 parts of neopentyl glycol dioleate, 45.0 parts of isooctyl oleate parts and 15.0 parts of trimethylolpropane oleate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pour point | aaaaa | aaaaa |

| cone penetration | aaaaa | aaaaa |

| drop melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com