A kind of resin polymer with high modulus and high glass transition temperature and preparation method thereof

A technology with high glass transition and transition temperature, applied in the field of resin-based composite materials, can solve the problems of high polymer brittleness, low glass transition temperature, and limitations, and achieve the effect of simple process and easy promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

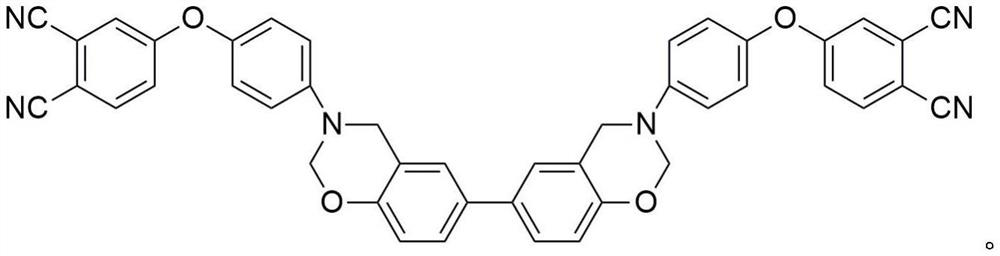

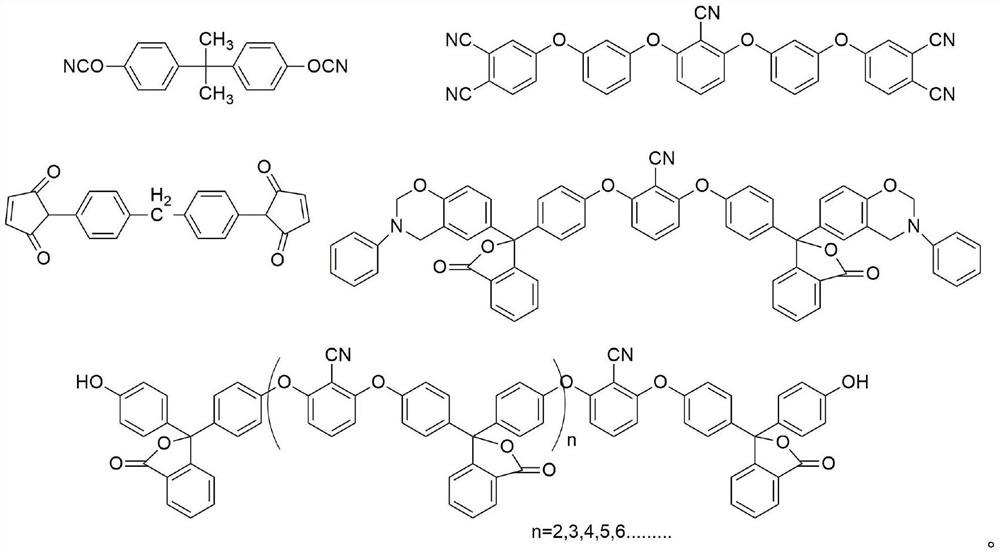

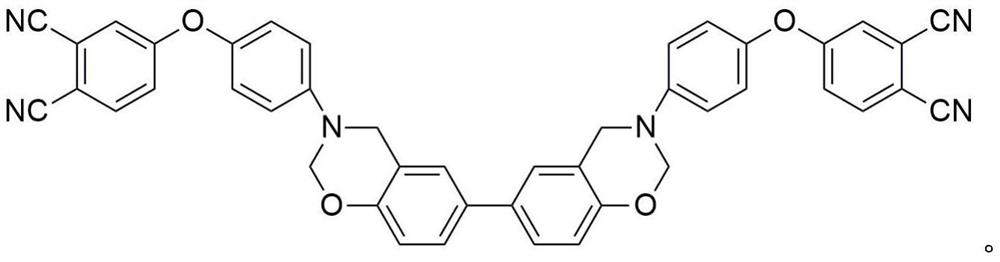

Method used

Image

Examples

Embodiment 1

[0051] (1) 14 grams of benzide nitrile-based resin and 6 grams of expanded agent (a dominated ether) were sequentially added to 15 ml N, N-dimethylformamide, resulting in a uniform transparent solution;

[0052] (2) 2 ml of toluene solvent is added to the uniform solution in (1), and the reflux temperature of the regulatory system is in the range of 120-155 ° C;

[0053] (3) The resulting solution system was slowly warmed, and the control system temperature was stirred in the range of 130-140 ° C for 2 hours, and the viscosity was weakly lifted uniform solution;

[0054] (4) Continue to increase the temperature to 150-155 ° C in (3), stir vigorously, and maintain the system temperature stirring reaction for 2 hours to obtain a viscosity of viscosity and increased viscosity;;

[0055] (5) Maintain the stirring rate, adjust the reaction device, receive a sewer device, and slowly evaporated the mixed solvent, and the viscosity of the reaction solution is significantly increased, and ...

Embodiment 2

[0060] (1) 14 grams of benzoxazine-based resin and 5 grams of expanded agent (bisphenol C) were sequentially added to 15 mln, N-dimethylformamide, resulting in a uniform transparent solution;

[0061] (2) 2 ml of toluene solvent is added to the uniform solution in (1), and the reflux temperature of the regulatory system is in the range of 120-155 ° C;

[0062] (3) The resulting solution system is slowly warmed, and the control system temperature is stirred in the range of 130-140 ° C for 1 hour, resulting in a uniform solution having a weak increase in viscosity;

[0063] (4) Continue to increase the temperature to 150-155 ° C in (3), stir vigorously, and maintain the system temperature stirring reaction for 3 hours to obtain a viscosity of viscosity and increased viscosity;;

[0064] (5) Maintain the stirring rate, adjust the reaction device, receive a sewer device, and slowly evaporated the mixed solvent, and the viscosity of the reaction solution is significantly increased, and...

Embodiment 3

[0069] (1) 14 grams of phenylphenylzanitrile-based resin and 4 grams of expansion agent (phenolphthalene aromatic ether nitrile) were sequentially added to 20 mL N, N-dimethylformamide to obtain a uniform transparent solution;

[0070] (2) 3 ml of toluene solvent is added to the homogeneous solution in (1), and the reflux temperature of the regulatory system is in the range of 120-155 ° C;

[0071] (3) The resulting solution system was slowly warmed, and the control system temperature was stirred in the range of 130-140 ° C for 2 hours, and the viscosity was weakly lifted uniform solution;

[0072] (4) Continue to increase the temperature to 150-155 ° C in (3), stir vigorously, and maintain the system temperature stirring reaction for 3 hours to obtain a viscosity of viscosity and increased viscosity;;

[0073] (5) Maintain the stirring rate, adjust the reaction device, receive a sewer device, and slowly evaporated the mixed solvent, and the viscosity of the reaction solution is s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

| storage modulus | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com