Mecanum wheel series branch chain leg and its omnidirectional mobile attitude adjustment platform

A mecanum wheel and branch chain technology, applied in the direction of motor vehicles, transportation objects, manufacturing tools, etc., can solve the problems of height increase, unfavorable high-precision docking and assembly of parts, and reduce the passability of trucks, so as to achieve high movement Accuracy, reduced overall height, increased arbitrariness effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to detail the technical content, structural features, achieved objectives and effects of the present invention, the following will be described in detail with reference to the accompanying drawings.

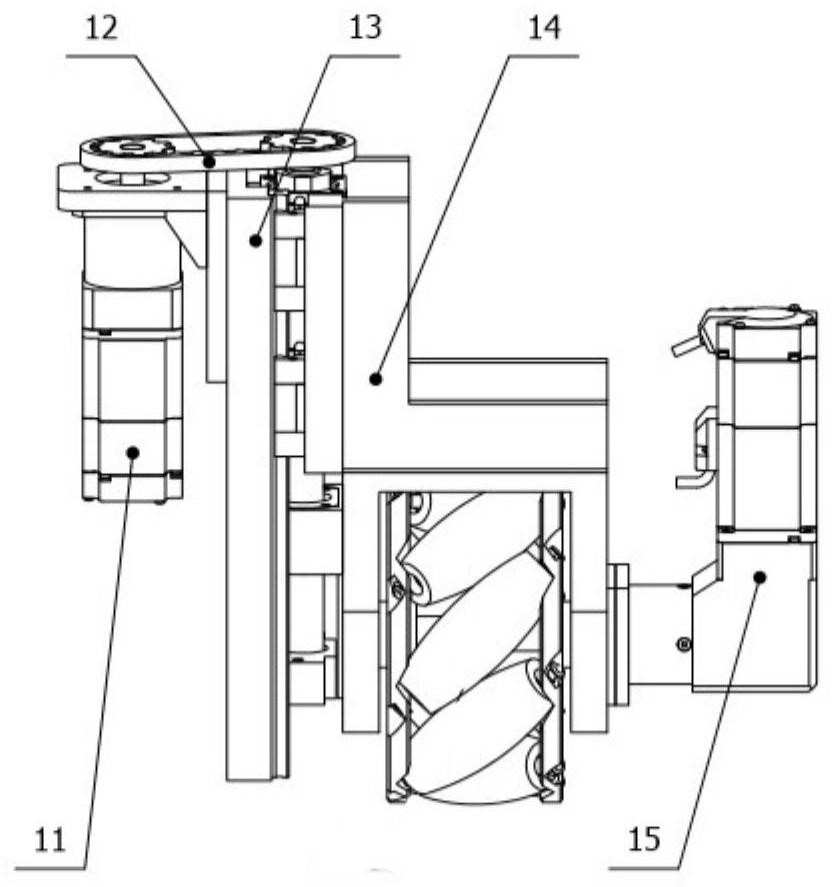

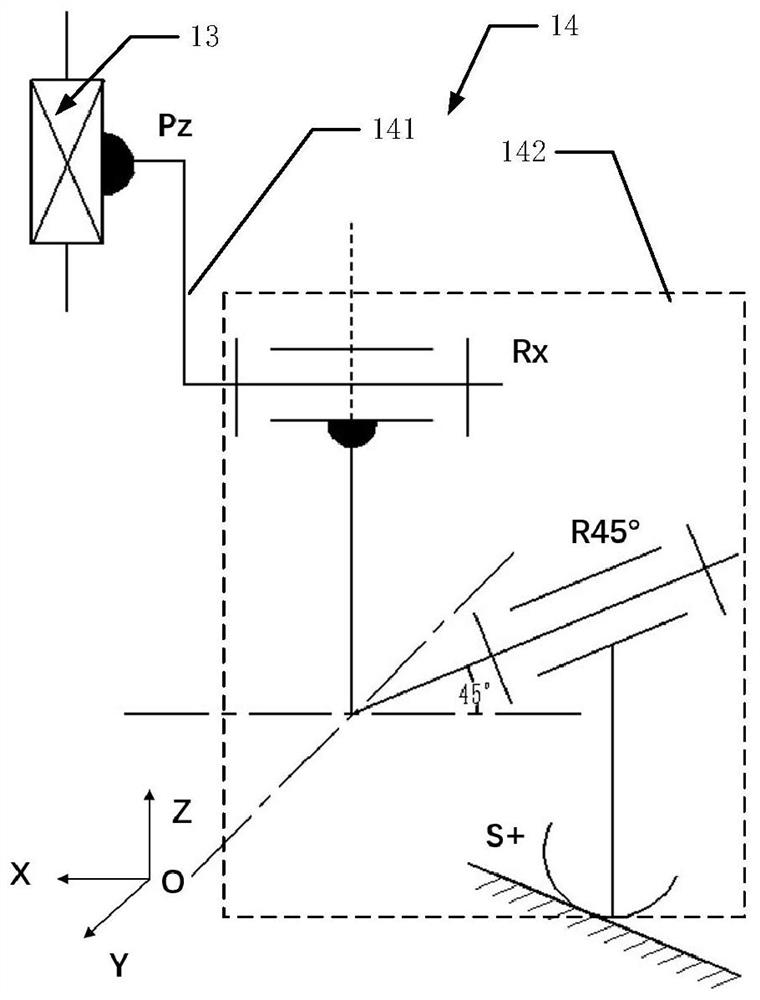

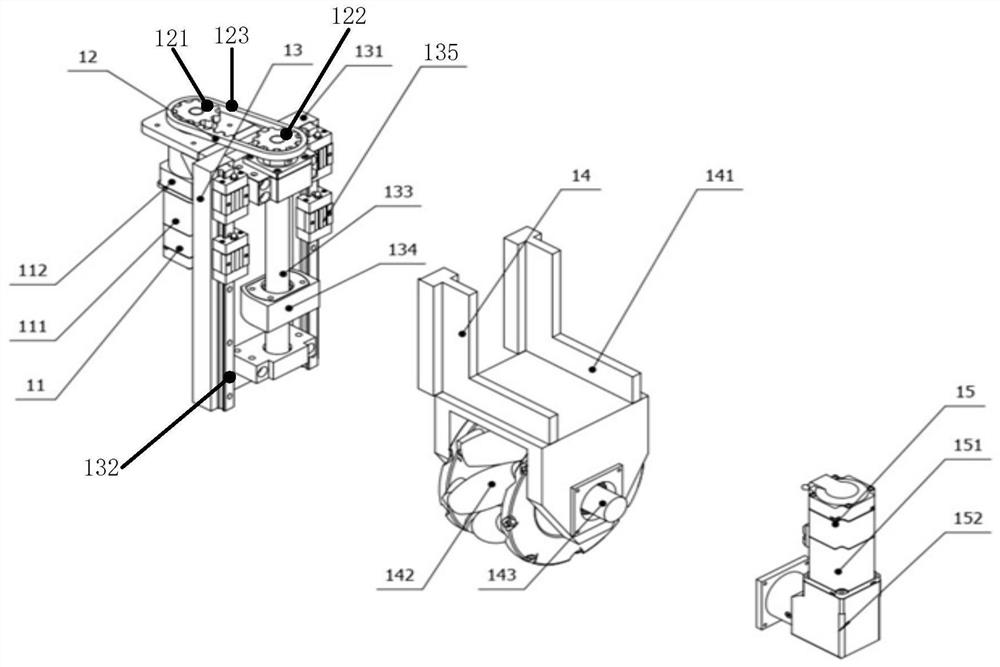

[0030] like Figures 1 to 3 As shown, it is a mecanum wheel series branch leg provided by the present invention. The left-handed mecanum wheel series branch leg 1 includes a left lift drive module 11, a left vertical lift module 13 and a left lift platform module 14. The left lift The drive module 11 includes a left servo motor 111 and a left planetary reducer 112. The left lift drive module 11 is mounted on the first end face of the left lift base plate 131, and the left servo motor 111 communicates with the left synchronous belt module 12 through the left planetary reducer 112. The left driving pulley 121 in the middle is connected; the left vertical lift module 13 includes a left lift base plate 131, a left guide rail 132, a left slider 135, a left ball screw 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com