Mobile remote operation and maintenance method for load cell in chemical equipment

A technology for weighing sensors and chemical equipment, applied in the field of automation equipment, can solve problems such as the inability to detect weighing sensors in time, achieve the effects of ensuring high-precision operation, improving operation and maintenance efficiency, and saving time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention clearer, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention. Obviously, the described embodiments are only It is a part of embodiments of the present invention, but not all embodiments.

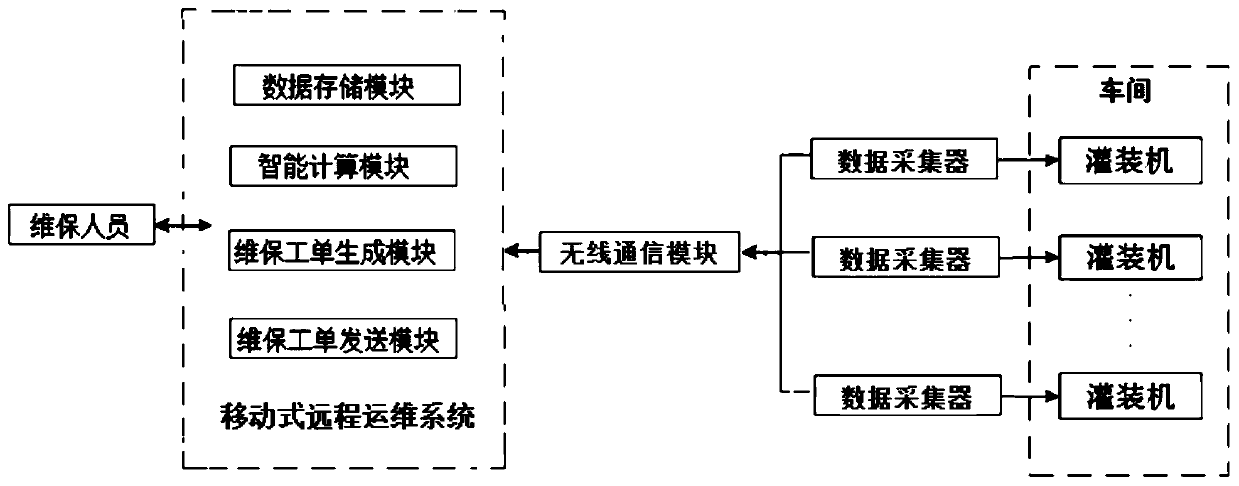

[0024] refer to figure 1 , the mobile remote operation and maintenance method of the load cell in the chemical equipment provided by the present invention specifically includes the following steps:

[0025] Step S1, open the hardware data interface on the explosion-proof filling machine, install the data collector (DS-Ex-D001) of the mobile remote operation and maintenance system; then install the wireless communication module, and keep the field terminal of the mobile remote operation and maintenance system connected to the communication ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com