Antifreeze device for dual-reagent oil well wellhead dosing pipeline and antifreeze method

An antifreeze device and pipeline technology, which is applied in the direction of wellbore/well components, earthwork drilling, cleaning equipment, etc., can solve the problems of large construction volume, large manual workload, and low degree of automation of electric heating cables, and reduce construction costs , Simplify the structure and ensure the effect of reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0038] refer to figure 1 , the first embodiment of the present invention relates to an antifreeze device for a double-medicine oil wellhead dosing pipeline, including an upper computer 1 and a lower computer 2 that are electrically connected, and also includes a No. 1 medicine tank 3 and a No. 2 medicine tank 7. The said The No. 1 medicine tank 3 is connected to the suction port of the same metering plunger pump 5 through the No. 1 solenoid valve 4, and the No. 2 medicine tank 7 is respectively connected to the suction port of the same metering plunger pump 5 through the No. 2 solenoid valve 8, and the discharge port of the metering plunger pump 5 passes through the wellhead The solenoid valve 6 is connected to the target well 9;

[0039] The No. 1 solenoid valve 4 , the metering plunger pump 5 , the wellhead solenoid valve 6 , and the No. 2 solenoid valve 8 are respectively electrically connected to the lower computer 2 .

[0040] It should be noted that in this embodiment, ...

no. 2 approach

[0046] The second embodiment of the present invention relates to an antifreeze device for the dosing pipeline at the wellhead of a dual-agent oil well, which includes an electrically connected upper computer 1 and a lower computer 2, and also includes a No. There is the No. 2 medicine tank 7 of the oil-based paraffin-repellent agent, the No. 1 medicine tank 3 is connected to the same metering plunger pump 5 through the No. 1 solenoid valve 4, and the No. 2 medicine tank 7 is respectively connected to the same metering plunger pump 5 through the No. 2 solenoid valve 8 The suction port of the metering plunger pump 5 is connected to the target well 9 through the wellhead solenoid valve 6;

[0047] The No. 1 solenoid valve 4 , the metering plunger pump 5 , the wellhead solenoid valve 6 , and the No. 2 solenoid valve 8 are respectively electrically connected to the lower computer 2 .

[0048] Specifically, the upper computer 1 is a remote control terminal, and the remote control te...

no. 3 approach

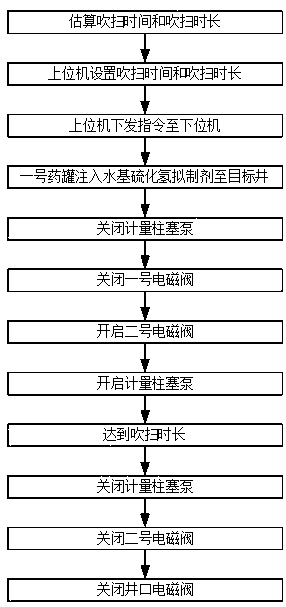

[0052] This embodiment provides an antifreeze method for the antifreeze device of the wellhead dosing pipeline of a dual-medicine oil well, such as figure 2 shown, including the following steps:

[0053] Step S1, pre-estimating the purge duration, setting the purge time and purge duration of the oil-based wax remover and anti-wax agent on the upper computer 1, and sending the purge time and purge duration to the lower computer 2;

[0054] Step S2, the lower computer 2 controls the No. 2 solenoid valve 8 to close, and at the same time controls the No. 1 solenoid valve 4, the metering plunger pump 5, and the wellhead solenoid valve 6 to open, and the water-based hydrogen sulfide preparation in the No. 1 medicine tank 3 is metered. The plug pump 5 sucks and discharges into the oil casing annulus of the target well 9 to complete the injection of the water-based hydrogen sulfide preparation;

[0055] Step S3, the lower computer 2 controls the No. 1 solenoid valve 4 and the meteri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com