Novel platform shield door frame with fire resistance, heat insulation, and sound insulation functions

A screen door and sound insulation technology, which is applied in the direction of fire doors, soundproof doors/windows, windows/doors, etc., can solve problems such as failure to guarantee the integrity of the door body, lack of thermal insulation and sound insulation performance, and failure to meet building energy-saving requirements, etc. , to achieve the effect of ensuring the safety of life and property, convenient installation and high degree of modular production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

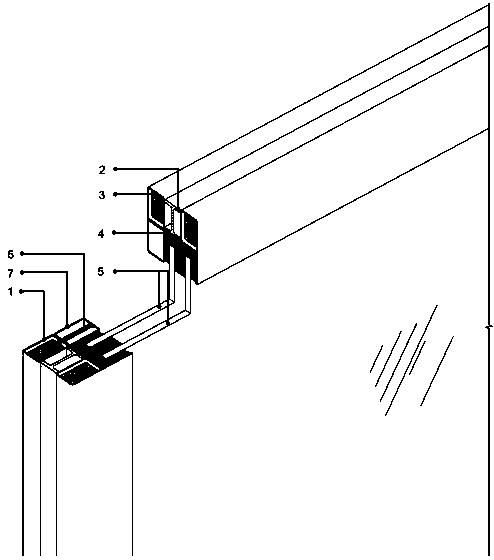

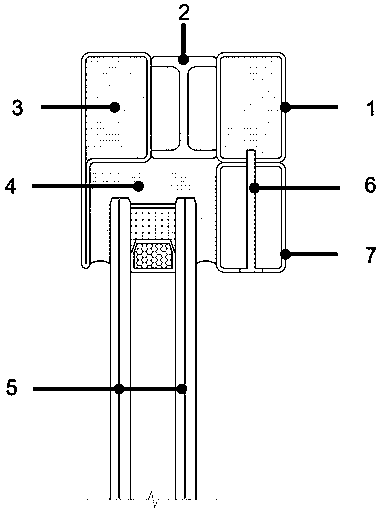

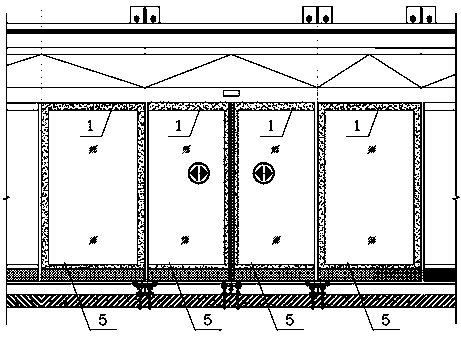

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0028] like Figure 1-3 As shown, a new type of platform screen door frame body with fire resistance, heat preservation and sound insulation functions, including stainless steel frame 1, broken bridge treatment components 2, fireproof insulation material 3, refractory rubber 4, laminated tempered glass 5, stainless steel countersunk screws 6. Stainless steel beading7.

[0029] The stainless steel frame 1 includes frames on both sides inside and outside the door, and its material is a thin-walled box-shaped section; the frame on both sides of the inside and outside is treated with a bridge-breaking treatment component 2, and the bridge-breaking treatment component 2 is connected with the stainless steel frame 1. Welding connection is adopted, and the material of the broken bridge treatment component 2 is thin-walled steel. The broken bridge treatment ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com