Concrete beam curing room

A curing room and cement technology, which is applied in the direction of protective buildings/shelters, building components, ceramic molding machines, etc. The effect of convenient disassembly and transfer, avoiding waste of water resources, and reducing the cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

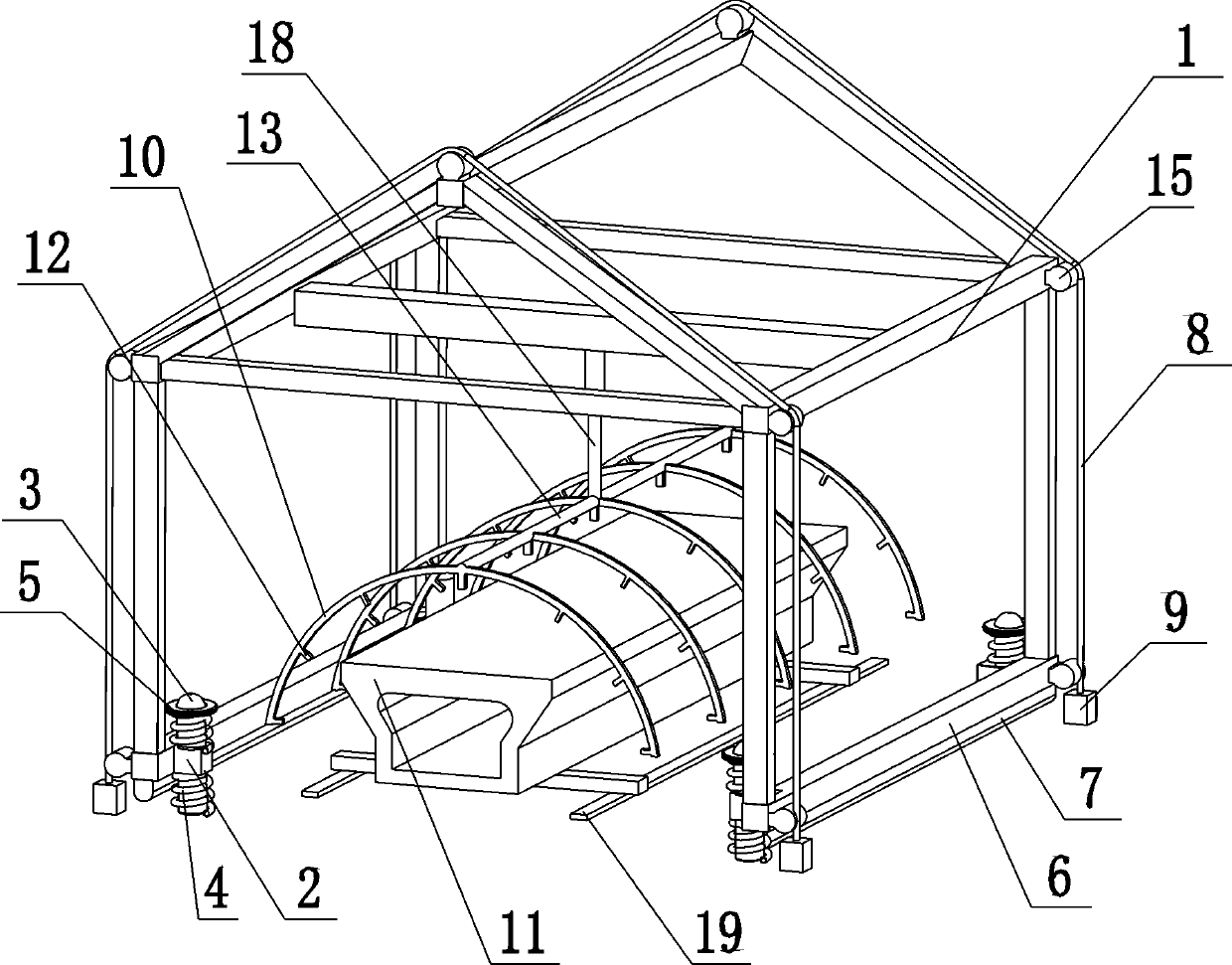

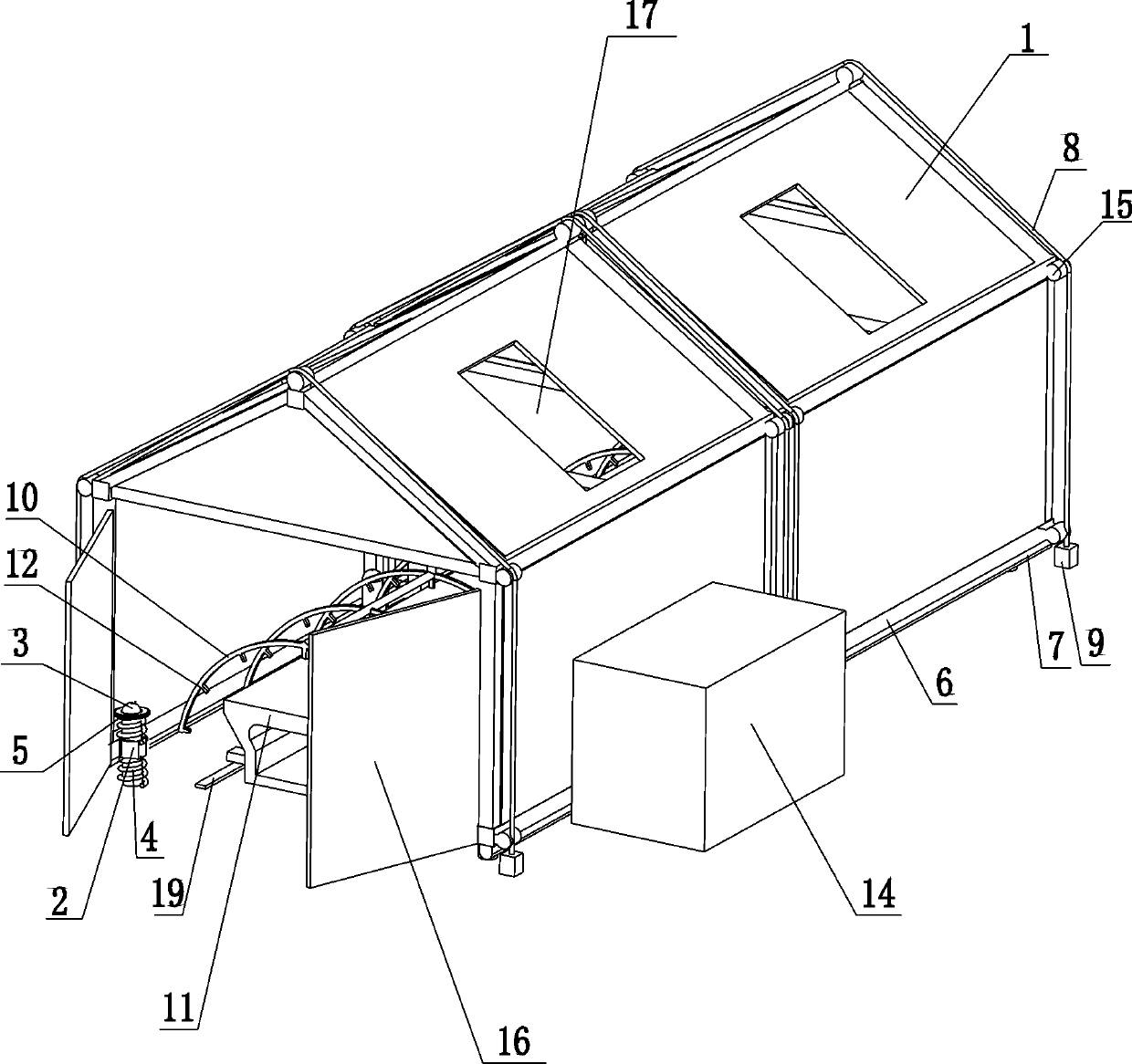

[0022] The present invention can be explained in detail through the following examples, and the purpose of disclosing the present invention is to protect all technical improvements within the scope of the present invention.

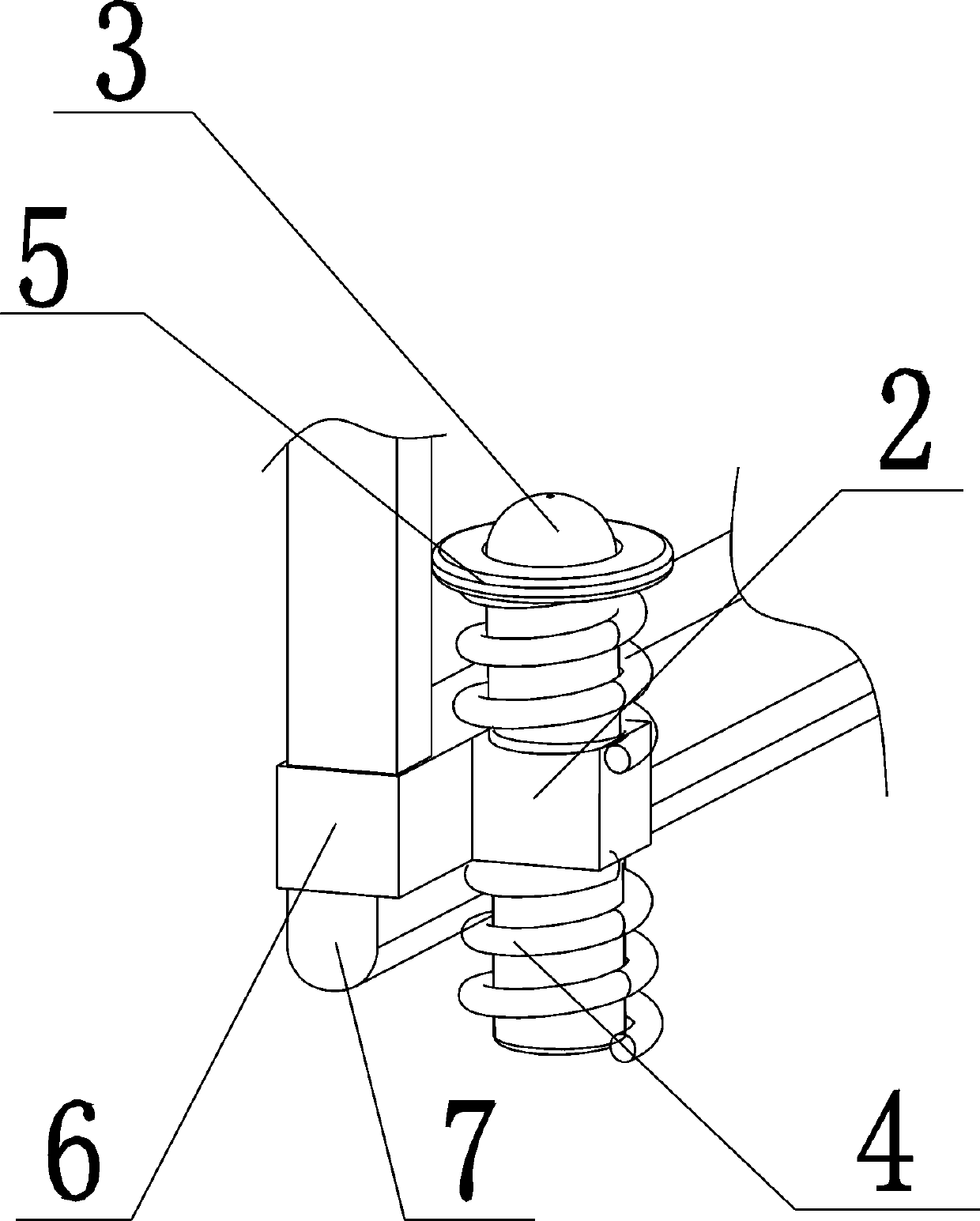

[0023] combined with Figure 1~3 , a cement beam maintenance room, comprising a maintenance system and a plurality of room bodies 1; the plurality of room bodies 1 are sequentially connected along the length direction of the room body 1, and the bottom four corners of the room body 1 are connected to the ground through a shock absorbing device Tightly connected, the damping device includes a slider 2, a guide post 3 and a spring 4, the bottom end of the guide post 3 is connected to the ground in a corresponding fastened connection, the body of the guide post 3 is provided with a slider 2, and the guide post 3 The top and bottom of the column body corresponding to the slider 2 are provided with a spring 4, and the top of the guide column 3 is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com