Composite material for fluid flow management

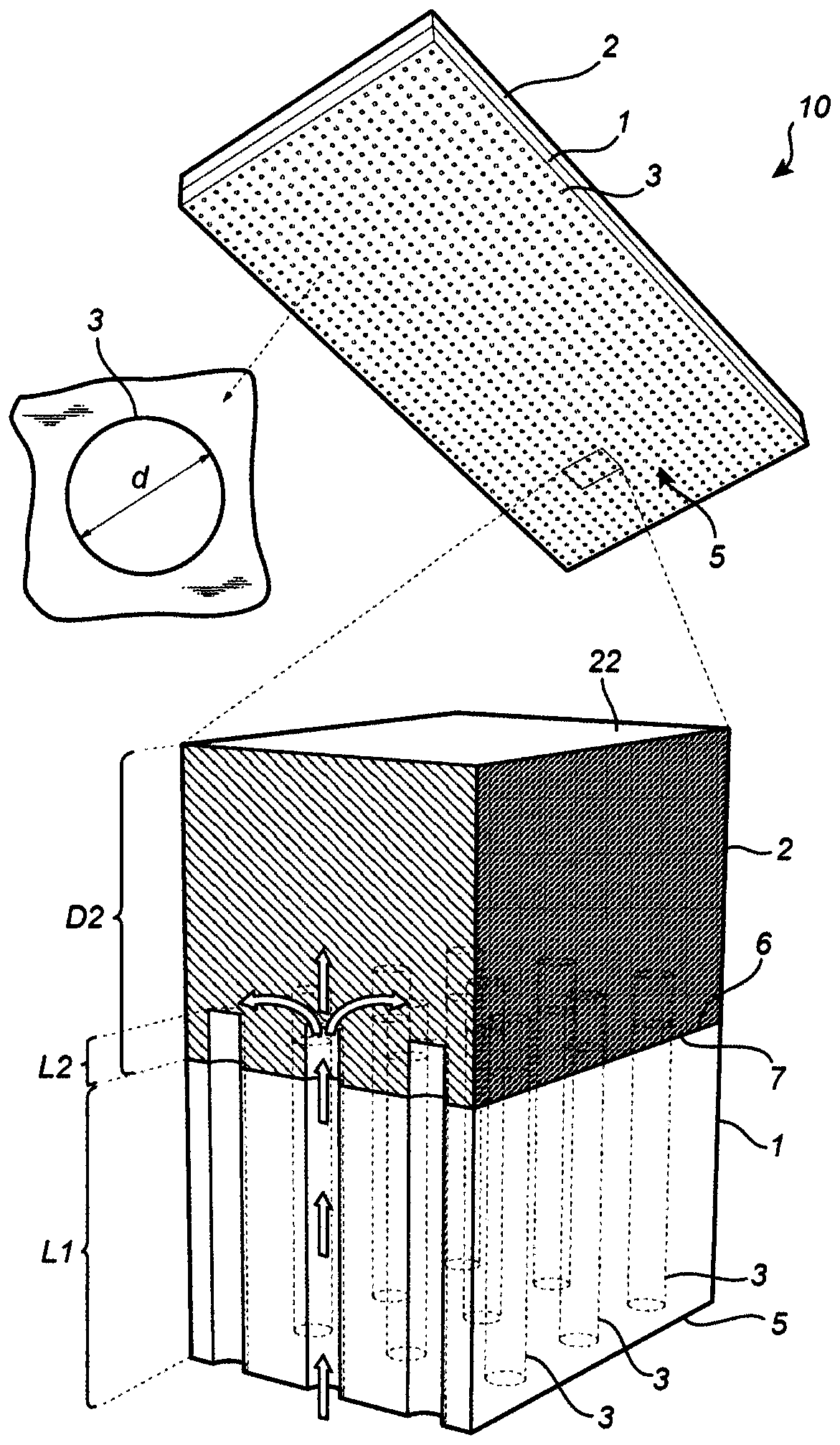

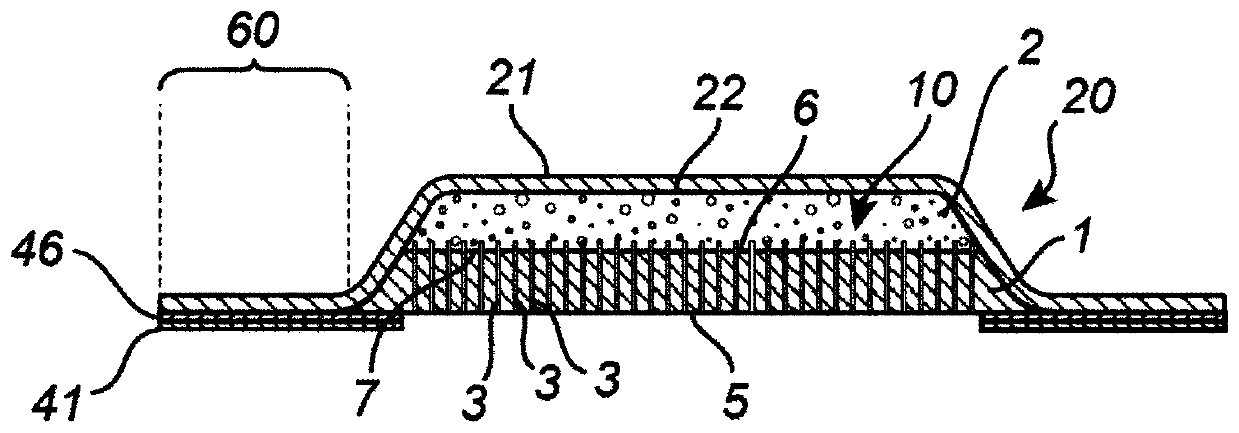

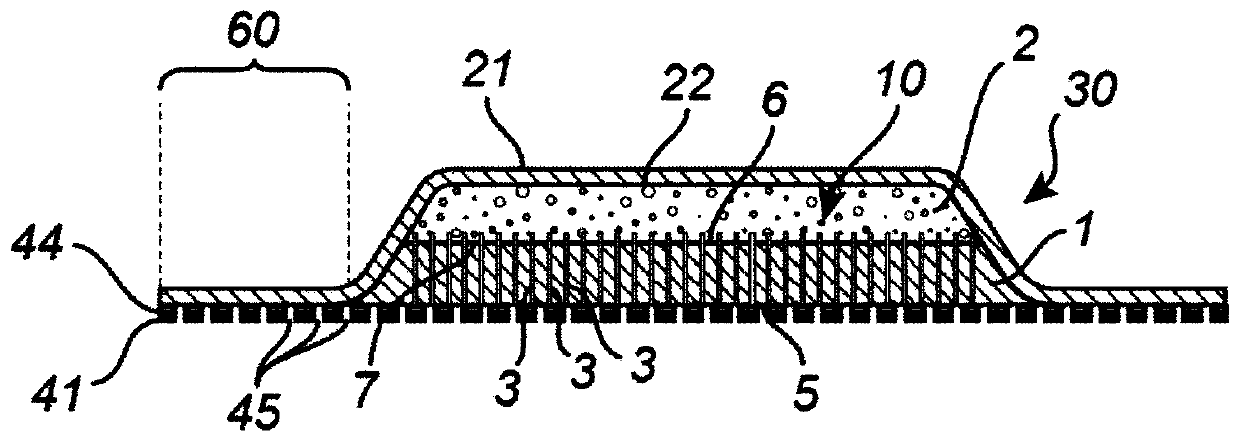

A technology of composite materials and absorbent materials, applied in the field of composite materials for fluid flow management, which can solve problems such as fluid flow obstruction, dressing leakage, and wound exudate transmission hindrance, to improve fluid delivery and eliminate cross-section effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0116] materials used

[0117] (size 10×10cm; product code: REF 603301; LOT: 16064983; used before: 2019-05); by Commercially available from Health Care (absorbent fiber material);

[0118] Max (size 10×10cm; REF 603201-00; LOT 15108622; used before: 2018-09); by Commercially available from Health Care; (absorbent foam);

[0119] Display Mount TM Adhesive (Jet Adhesive; 140A02PL6; EXP2017 / 05; MSDS No. 27-7170-7 / 16.06.2014); commercially available from 3M.

[0120] Preparation of the embodiment

[0121] In two application steps, apply the spray adhesive from a distance of 20cm to Max products on the foam side. in will Allow the adhesive spray coat to rest for 30 seconds before applying the product to the adhesive coat by hand.

[0122] One way to estimate the amount of binder is by comparing the A thin plastic film (pre-weighed) was sprayed in the same manner as the Max product and the coated film was subsequently weighed. The adhesive coat weight was calc...

Embodiment 2

[0126] Example 2 - Absorbency / Liquid Distribution Test

[0127] Absorbency was tested using an inclined plane with an inclination angle of 60° according to the test method described in detail below. The purpose of the test method described is to determine the absorbency and liquid distribution of a material exposed to compression and gravity when the test liquid is added at a constant flow rate, eg one intent of the test is to simulate a wound treatment situation.

[0128] General description of the test method:

[0129] use as image 3 The shown inclined plane test device, wherein the test device includes a fixed inclined test plate 11 (typically made of resin glass) inclined at 60 degrees. Before starting the test, the following preparations were prepared: 1) a syringe pump was filled with the test liquid (solution A according to EN 13726-1), including the tube up to the outlet hole 16; 2) a test piece of 100×100 mm was cut; 3) using The thickness gauge measures the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com