Iron shell and tooth permanent magnet spherical motor cogging torque analysis method

A technology of cogging torque and spherical motor, which is applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., can solve the problems that the output torque cannot reach the maximum, the magnetic circuit analysis is complicated, etc., and achieve accurate control of the ball machine, The effect of increasing the electromagnetic torque of the ball machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

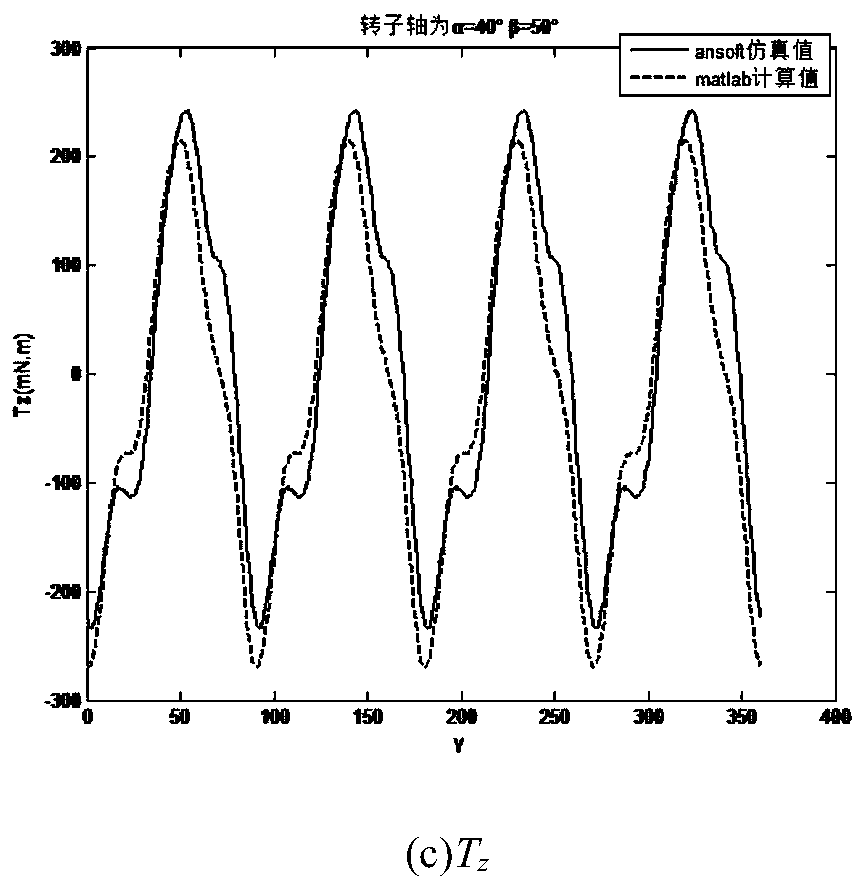

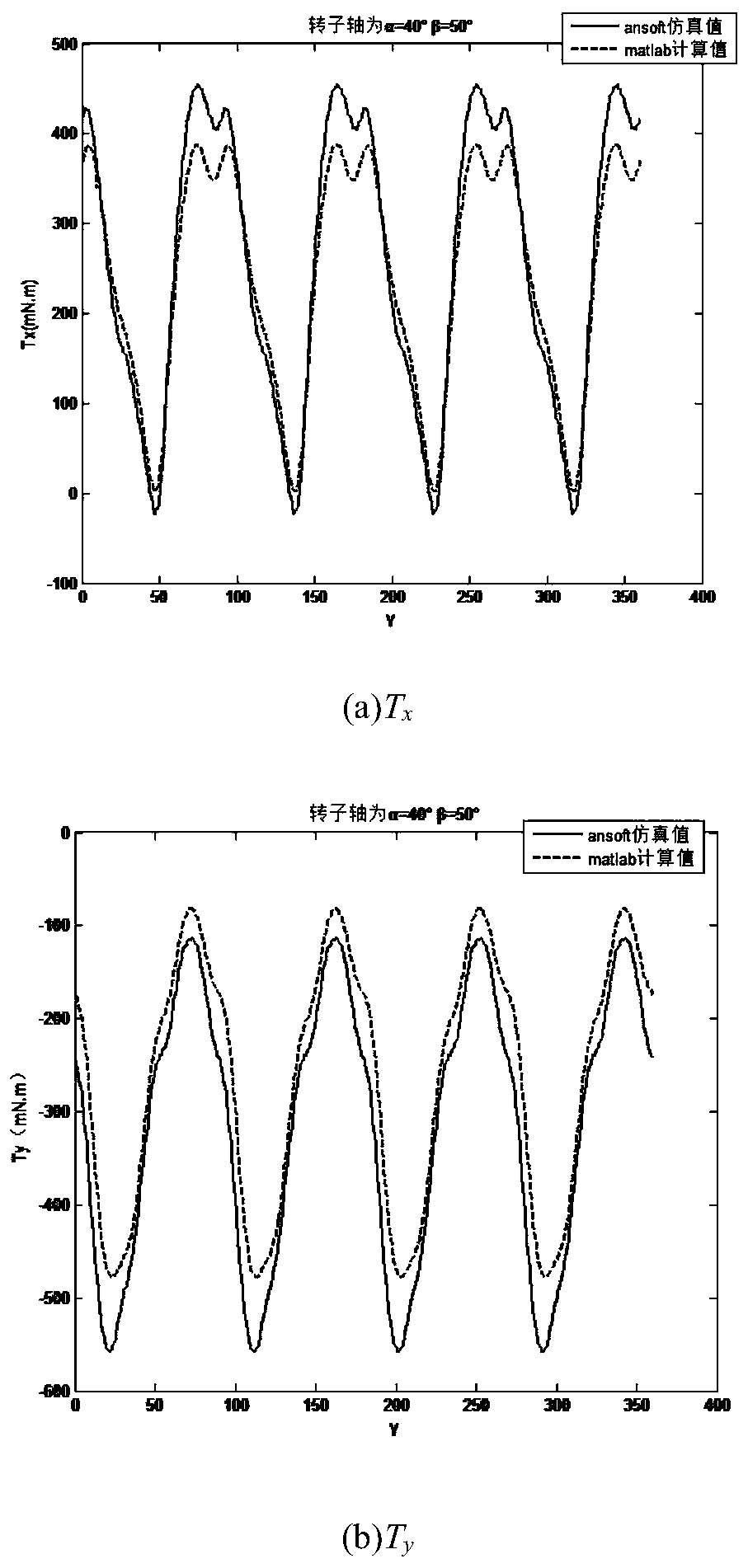

[0043] The present invention provides a method for obtaining the cogging torque of the permanent magnet spherical motor with iron shell and teeth at any position of the rotor. The present invention will be described in detail below in conjunction with the accompanying drawings and implementation. The specific implementation steps of the present invention are as follows:

[0044] (1) Eighteen-tooth unipolar cogging torque expression:

[0045] In the present invention, the 6-8 type polyhedral permanent magnet spherical motor is taken as an example. The stator of the 6-8 type polyhedral permanent magnet spherical motor includes a ferromagnetic stator shell and 18 ferromagnetic stator teeth, wherein the stator teeth are distributed in the virtual interior of the sphere. Connect the six vertices of the regular octahedron and the midpoints of the twelve edges; the rotor in this unipolar model includes a ferromagnetic rotor inner shell and an N-shaped magnetic pole, which adopts a cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com