Steel bar supporting method for improving construction quality

A support method and steel bar technology, which is applied in the processing of building materials, construction, building construction, etc., can solve the problems of fixed shape and size of long iron benches, inconvenient inventory, and inability to apply steel bar layers, etc., and achieve the effect of reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

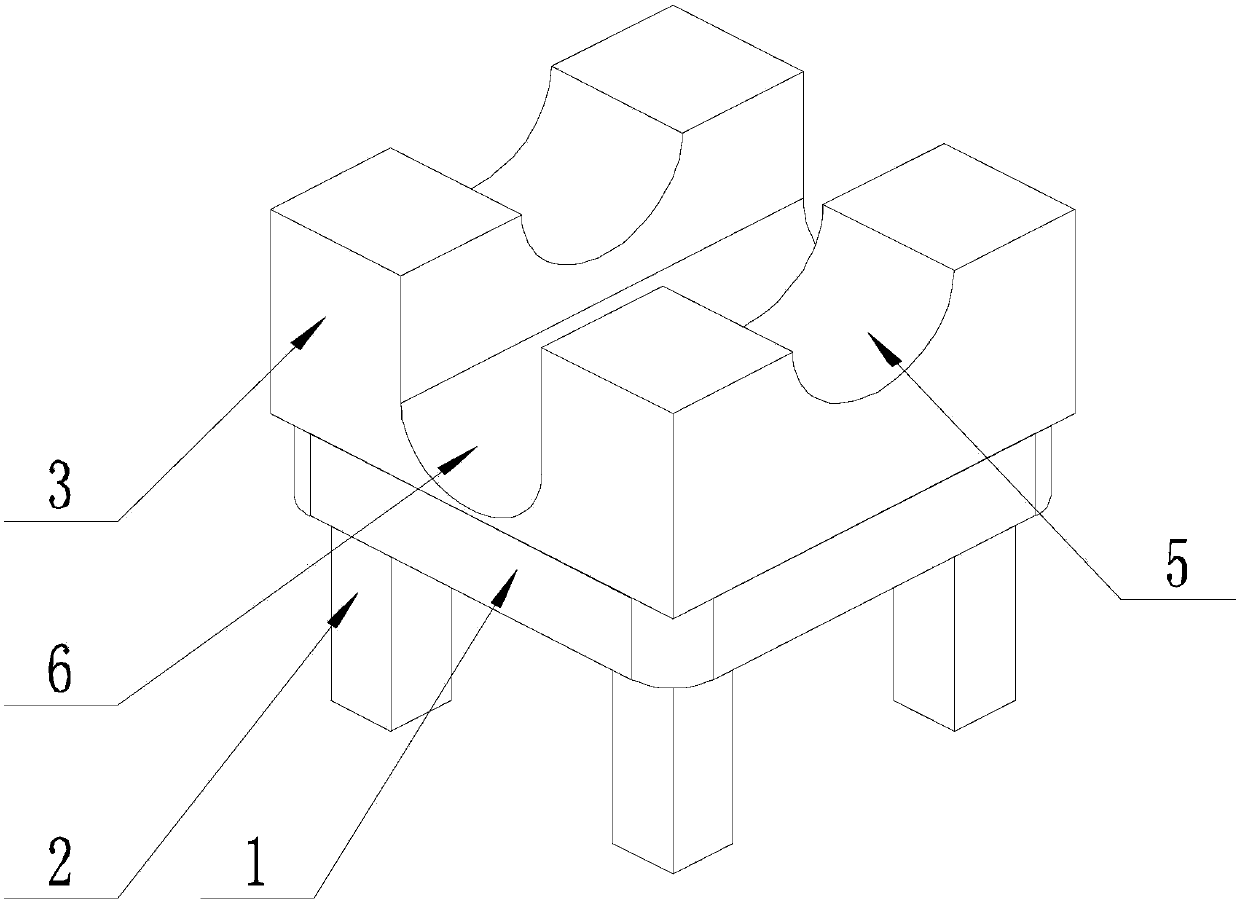

[0029] Such as Figure 1-Figure 5 Shown, the steel bar support method that the present invention improves construction quality, comprises the steps:

[0030] Step A: Insert the end of the installation shaft 8 away from the support block 3 into the installation hole 4;

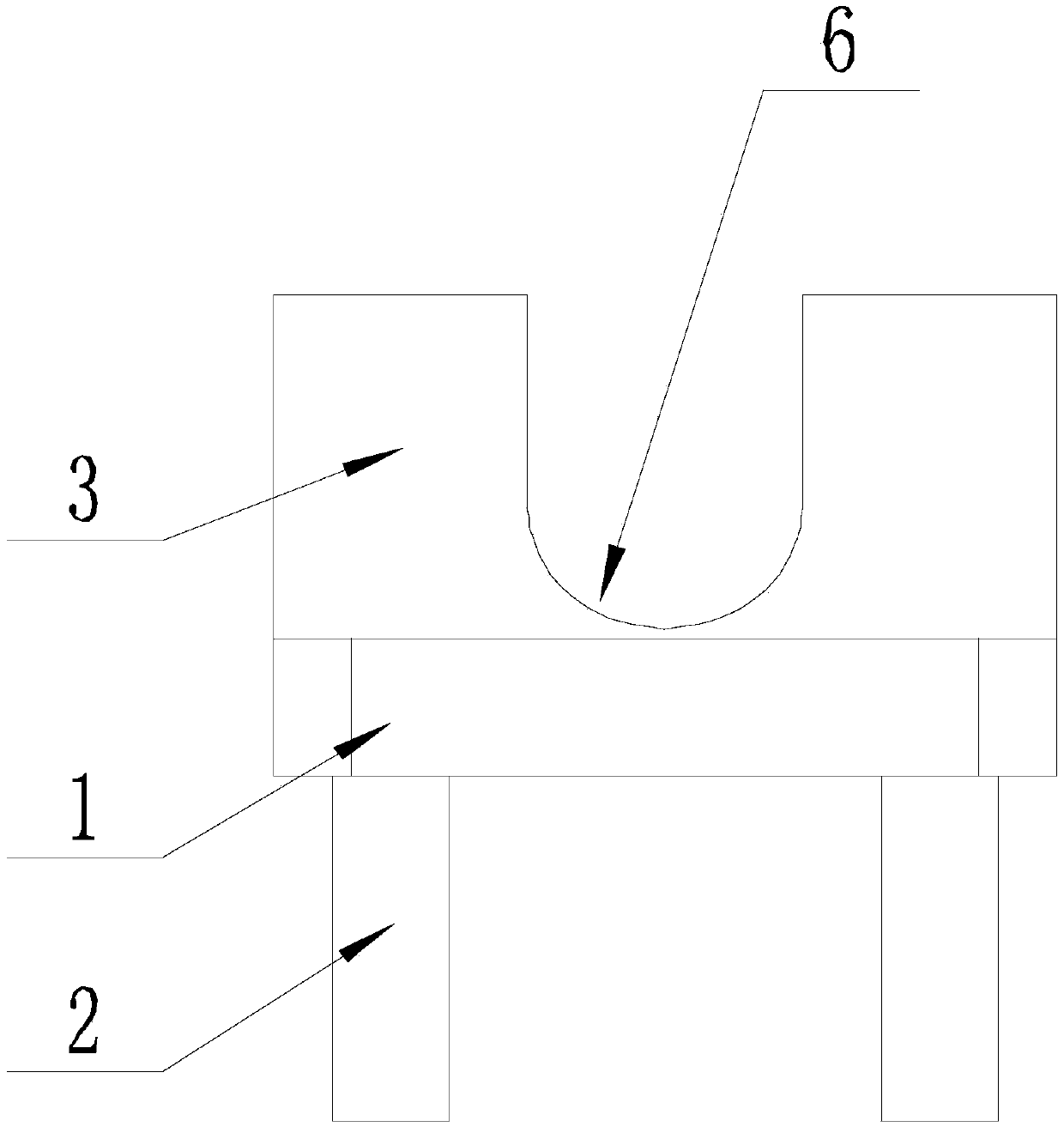

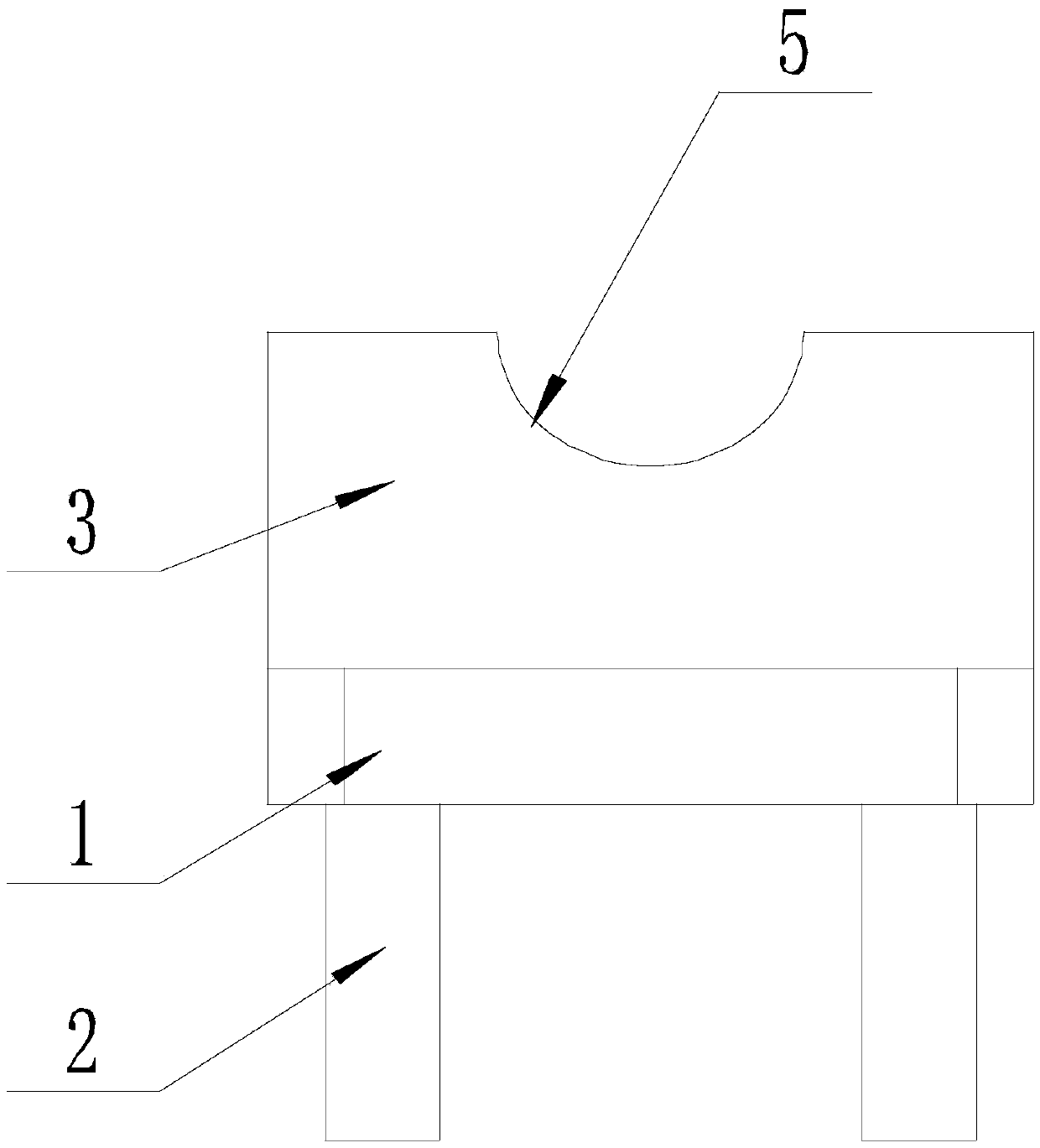

[0031] Step B: erect the long iron bench body on the intersection of steel bars, and make the steel bars between the upper and lower layers of steel bars at the intersection located in the first through groove 5 and the second through groove 6 respectively;

[0032] The long iron bench body includes a support plate 1 and several support legs 2 supporting the support plate 1 on the ground, the support block 3 is located above the support plate 1, and the installation hole 4 is arranged on the top of the support plate 1 , the installation shaft 8 is arranged on the bottom of the support block 3, when the installation shaft 8 is inserted into the installation hole 4, the bottom surface of the support block 3 is i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com