A swinging self-resetting damping system and construction method for center columns of underground stations

An underground station, self-reset technology, applied in the direction of columns, shockproof, piers, etc., can solve the problems of structural damage, reduction of vertical bearing capacity, crushing, etc., to help construction positioning, increase plastic area, energy consumption good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

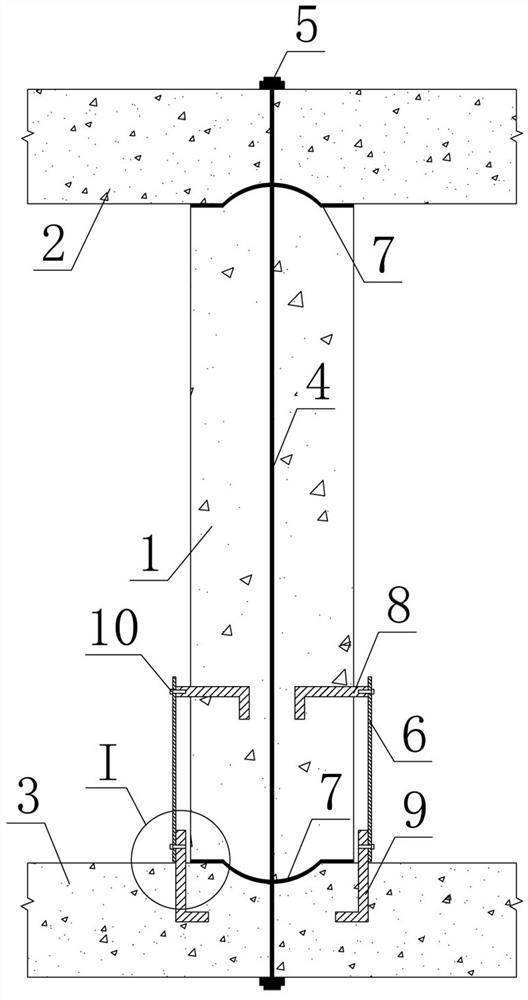

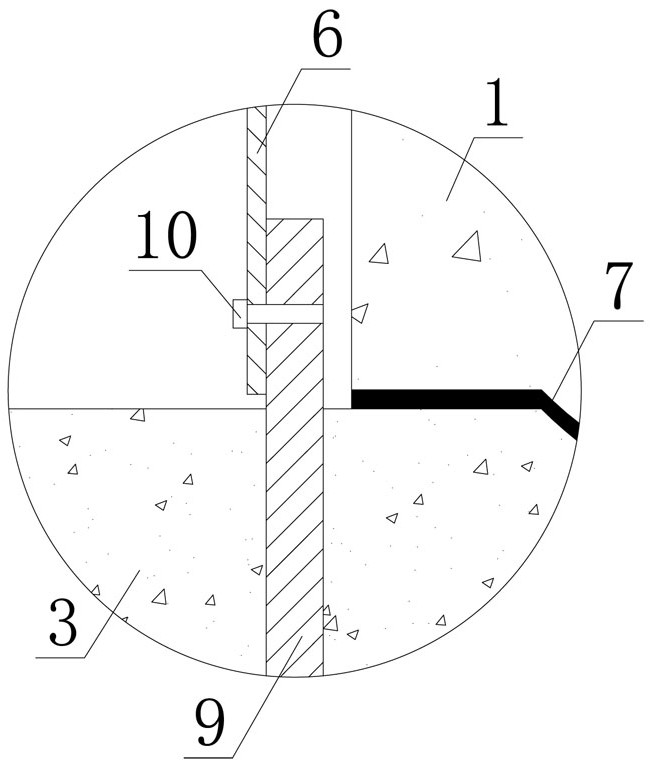

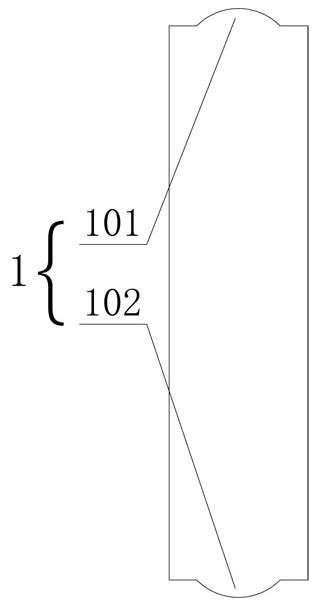

[0038] Such as Figure 1 to Figure 5As shown, a sway self-resetting shock absorbing system for the central column of an underground station includes a central column 1 and a top plate 2 and a bottom plate 3 directly connected to the central column 1. The top plate 2, the central column 1 and the bottom plate 3 pass through The knotted prestressed steel strands 4 are connected into a whole, the unbonded prestressed steel strands 4 pass through the center of the center column 1 vertically, and the upper ends of the unbonded prestressed steel strands 4 are anchored to the top plate 2 through anchors 5 The upper and lower ends are anchored to the bottom of the bottom plate 3 through the anchorage 5; the upper end of the central column 1 has a hemispherical upper raised joint 101 and a steel backing plate 7 with hemispherical protrusions, and the corresponding position of the lower end of the top plate 2 is reserved with a hemispherical The lower end of the center column 1 has a he...

Embodiment 2

[0050] The basic structure and method of this embodiment are the same as those of Embodiment 1, and the similarities will not be described in detail. The difference is:

[0051] The top plate 2 and the bottom plate 3 are constructed by cast-in-place method, and the specific steps are as follows:

[0052] a The center column 1 is constructed by factory prefabrication and on-site assembly, the center of which uses corrugated pipes to reserve unbonded prestressed steel strand holes, and the hook end of the center column pre-embedded steel plate 8 is pre-embedded at the designed position. The hemispherical protruding steel backing plate 7 is correspondingly pre-embedded at the top and bottom of the center column 1. After the concrete is poured and prefabricated, the steel backing plate 7 is adhered to the top and bottom of the center column 1 to form a whole with the center column 1;

[0053] b Base plate 3 is cast-in-place construction, the hook end of base plate pre-embedded ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com