Hydraulic seal type steel gate

A hydraulic sealing and gate technology, which is applied in the field of steel gates, can solve problems such as large gap between steel gates and gate frames, safety accidents, water-stop rubber wear, etc., and achieve the effect of simple structure and reduced opening and closing force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

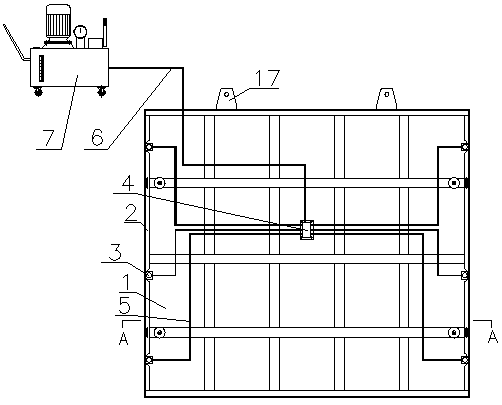

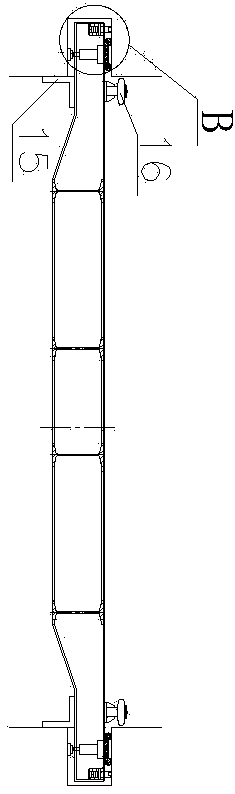

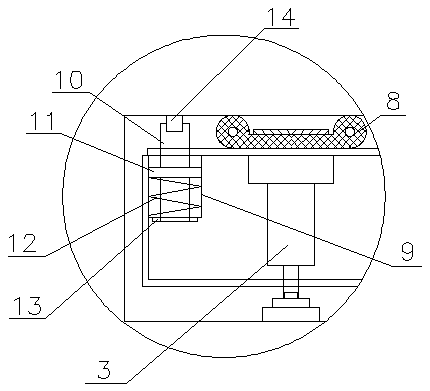

[0015] A hydraulically sealed steel gate, comprising a steel gate 1 and a gate frame 2, the steel gate 1 is placed in a gate groove inside the gate frame 2, and a plurality of hydraulic jacks 3 are arranged horizontally between the steel gate 1 and the gate frame 2 , the inside of the steel gate 1 is provided with a one-way diverter valve 4, the one-way diverter valve 4 is connected to the hydraulic jack 3 through a number of high-pressure hoses 5, the one-way diverter valve 4 is connected to a high-pressure electric oil pump 7 through a pipeline 6, and the steel gate 1 There are double P-shaped rubbers 8 between both sides of the upstream surface and the gate frame 2. The hydraulic jack 3 is located on the back of the double P-shaped rubbers 8. The piston rod of the hydraulic jack 3 penetrates the steel gate 1. Both sides of the gate 1 facing the water are respectively provided with holes, and a spring seat 9 is installed in the hole, and a telescopic rod 10 is arranged in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com