A kind of ferric oxide photocatalyst heat-treated under nitrogen atmosphere, preparation method and application thereof

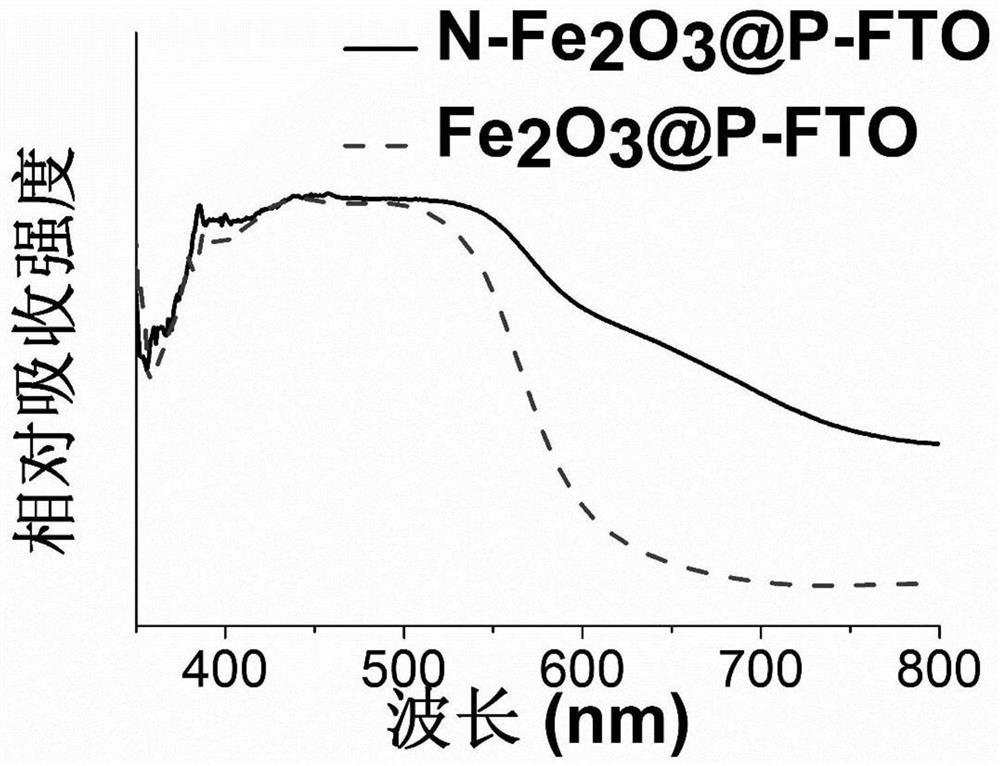

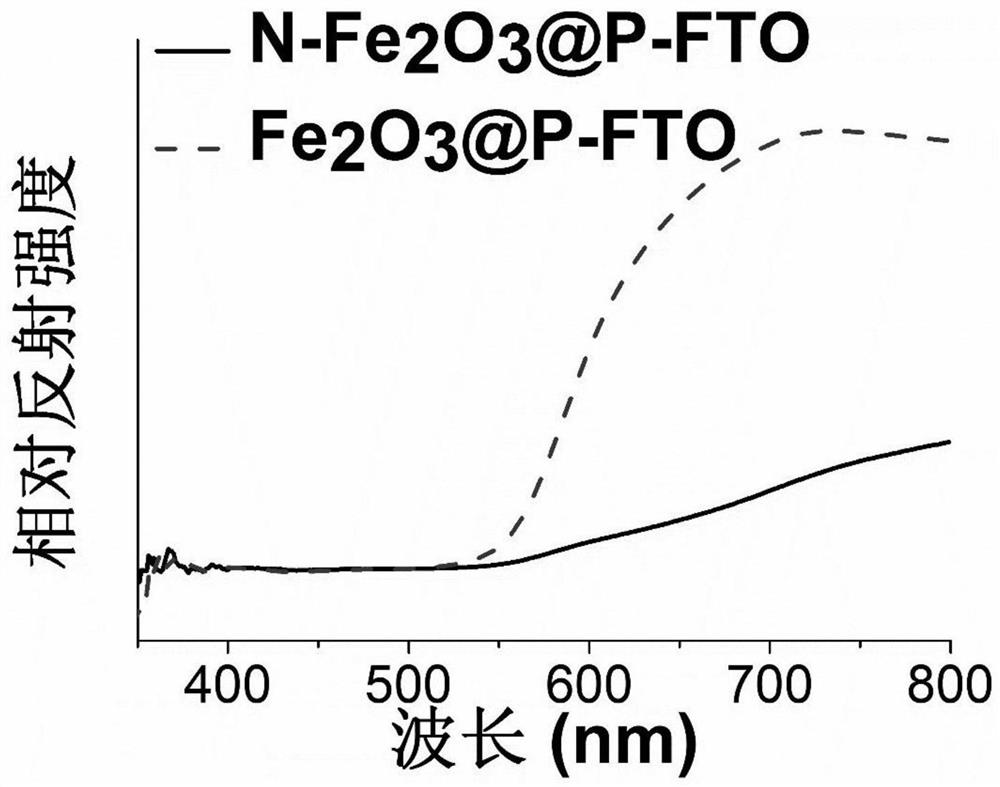

A technology of ferric oxide and photocatalyst, which is used in catalyst activation/preparation, physical/chemical process catalyst, iron oxide/iron hydroxide, etc., can solve the problem of broadening the visible light response range of photocatalyst and unable to enhance photocatalyst well. Light absorption capacity and other issues, to achieve the effect of expanding the visible light response range, improving the light absorption capacity, and strengthening the light absorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

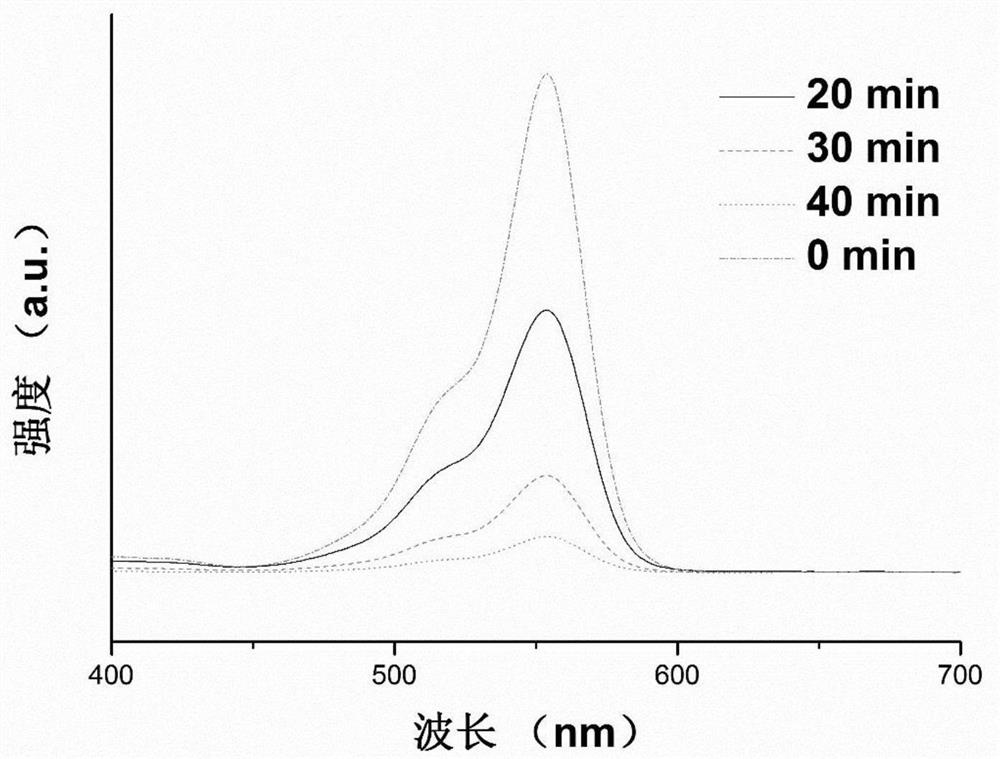

Examples

Embodiment 1

[0036] 1. Take 0.05 mmol of ferric (III) chloride hexahydrate and place it in 20 ml of deionized water to ultrasonicate until completely dissolved to obtain a ferric (III) chloride precursor solution.

[0037] 2. The clean fluorine-doped tin oxide conductive substrate is placed obliquely on the inner wall of the clean high-temperature reactor liner, and the conductive surface of the fluorine-doped tin oxide conductive substrate faces outward. Iron trichloride (III) precursor solution is added to the inner tank on which the fluorine-doped tin oxide conductive glass is placed, and the precursor solution does not pass over the top of the glass. The high-temperature reaction kettle containing the fluorine-doped tin oxide conductive substrate and iron(III) chloride precursor solution was transferred to a blast drying oven, and hydrothermally reacted at 100 °C for 1 h, cooled to room temperature, and taken out, and deionized water was used to fluorine-doped The tin oxide conductive ...

Embodiment 2

[0043] 1. Take 0.1 mmol of ferric (III) chloride hexahydrate and place it in 20 ml of deionized water to ultrasonicate until completely dissolved to obtain a ferric (III) chloride precursor solution.

[0044] 2. The clean indium-doped tin oxide conductive substrate is placed obliquely on the inner wall of the clean high-temperature reactor liner, and the conductive surface of the fluorine-doped tin oxide conductive substrate faces outward. Iron trichloride (III) precursor solution is added to the inner tank on which the fluorine-doped tin oxide conductive glass is placed, and the precursor solution does not pass over the top of the glass. The high-temperature reactor containing fluorine-doped tin oxide conductive substrate and iron(III) chloride precursor solution was transferred to a blast drying oven, and hydrothermally reacted at 160 °C for 1 h, cooled to room temperature, and taken out, and deionized water was used to fluorine-doped The tin oxide conductive substrate was r...

Embodiment 3

[0047] 1. Take 0.2 mmol of ferric (III) chloride hexahydrate and place it in 20 ml of deionized water to ultrasonicate until completely dissolved to obtain a ferric (III) chloride precursor solution.

[0048] 2. The clean fluorine-doped zinc oxide conductive substrate is placed obliquely on the inner wall of the clean high-temperature reactor liner, and the conductive surface of the fluorine-doped tin oxide conductive substrate faces outward. Iron trichloride (III) precursor solution is added to the inner tank on which the fluorine-doped tin oxide conductive glass is placed, and the precursor solution does not pass over the top of the glass. The high-temperature reaction kettle containing the fluorine-doped tin oxide conductive substrate and iron(III) chloride precursor solution was transferred to a blast drying oven, and hydrothermally reacted at 80 °C for 4 h, cooled to room temperature, and taken out, and deionized water was used to fluorine-doped water. The tin oxide condu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com