Method for preparing yoghurt, base material and yoghurt prepared thereby

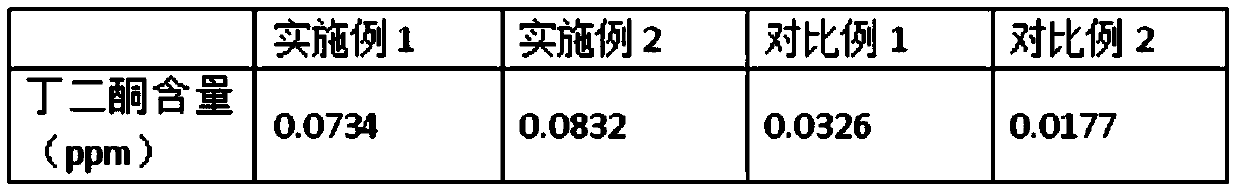

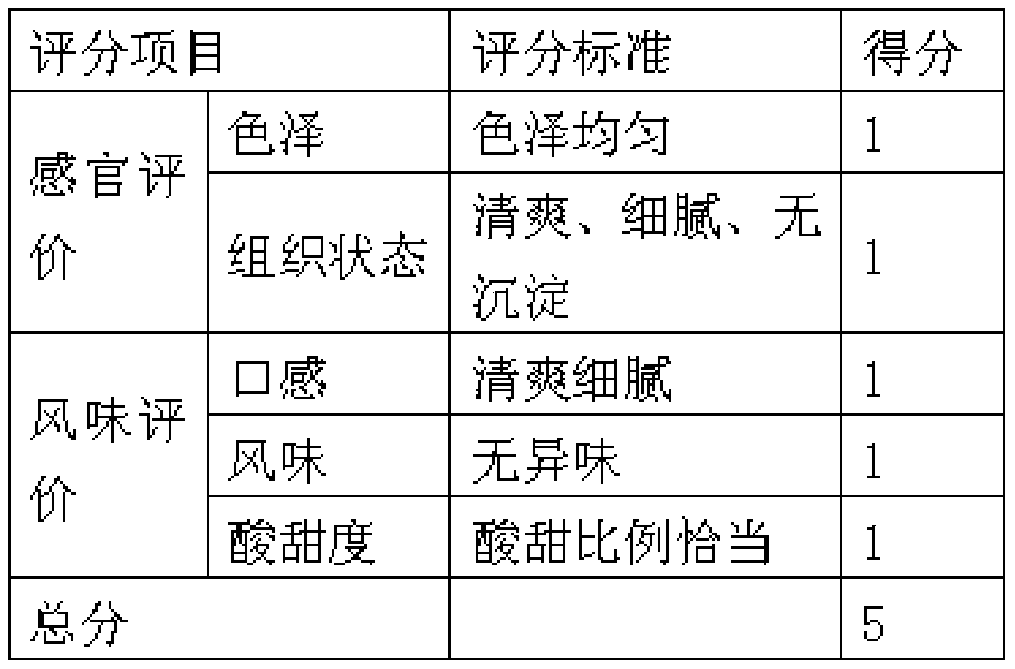

A technology for yogurt and base material, which is applied in the directions of bacteria, applications, and dairy products used in food preparation, can solve the problems of insufficient aroma of yogurt, low content of butanedione, and poor taste, and achieve good sensory flavor and pure flavor. , the effect of reducing the risk of fermentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Example 1 Full-fat yoghurt with better sensory quality and its preparation method

[0050] 1. Raw material pretreatment:

[0051] 1. Take 1000kg of raw milk (the sum of casein and whey protein content is 3.1% by weight), preheat 10% by weight of raw milk to 55°C, enter the skim separator, and remove fat to obtain 90kg of skim milk and 10kg of cream, the fat content in the skim milk is <0.6% by weight.

[0052] 2. The skim milk was subjected to ultrafiltration to obtain 39 kg of protein concentrate and 51 kg of permeate, and the protein content in the protein concentrate was 8% by weight.

[0053] 3. Microfilter the protein concentrate to remove 6kg of whey solution, so that the ratio of casein to whey protein is 8.1:1.9.

[0054] 4. Mix 33kg of protein concentrate with 10kg of removed cream and 5.67kg of permeate after ultrafiltration, so that the total protein content is the same as that of raw milk without pretreatment.

[0055] 5. Preheat the treated raw milk to 5...

Embodiment 2

[0064] Embodiment 2 has better organoleptic quality high-protein yoghurt and preparation method thereof

[0065] 1. Raw material pretreatment:

[0066] 1. Take 1000kg of raw milk (protein content 3.3% by weight), preheat 30% by weight of raw milk to 55°C, enter the skim separator, remove fat to obtain 270kg of skim milk and 30kg of cream (skim milk: cream) , the fat content in the skim milk is <0.6% by weight.

[0067] 2. The skim milk was subjected to ultrafiltration to obtain 105 kg of protein concentrate and 165 kg of permeate. The protein content in the protein concentrate was 8.5% by weight.

[0068] 3. Microfilter the protein concentrate to remove 4.7kg of whey protein, so that the ratio of casein to whey protein is 9.5:0.5.

[0069]4. Mix 100.3 kg of the adjusted protein concentrate with 110 kg of ultrafiltered permeate and 30 kg of defatted cream, so that the total protein content reaches 6% by weight.

[0070] 5. Preheat the treated raw milk to 55°C, add fructose s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com