Modular permanent magnet compound self-gearing servo motor based on alternating poles

A technology of servo motors and alternating poles, which is applied to magnetic circuits, electromechanical devices, and electrical components. The effect of reducing the back EMF distortion rate, reducing the amount of permanent magnets, facilitating processing and post-maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

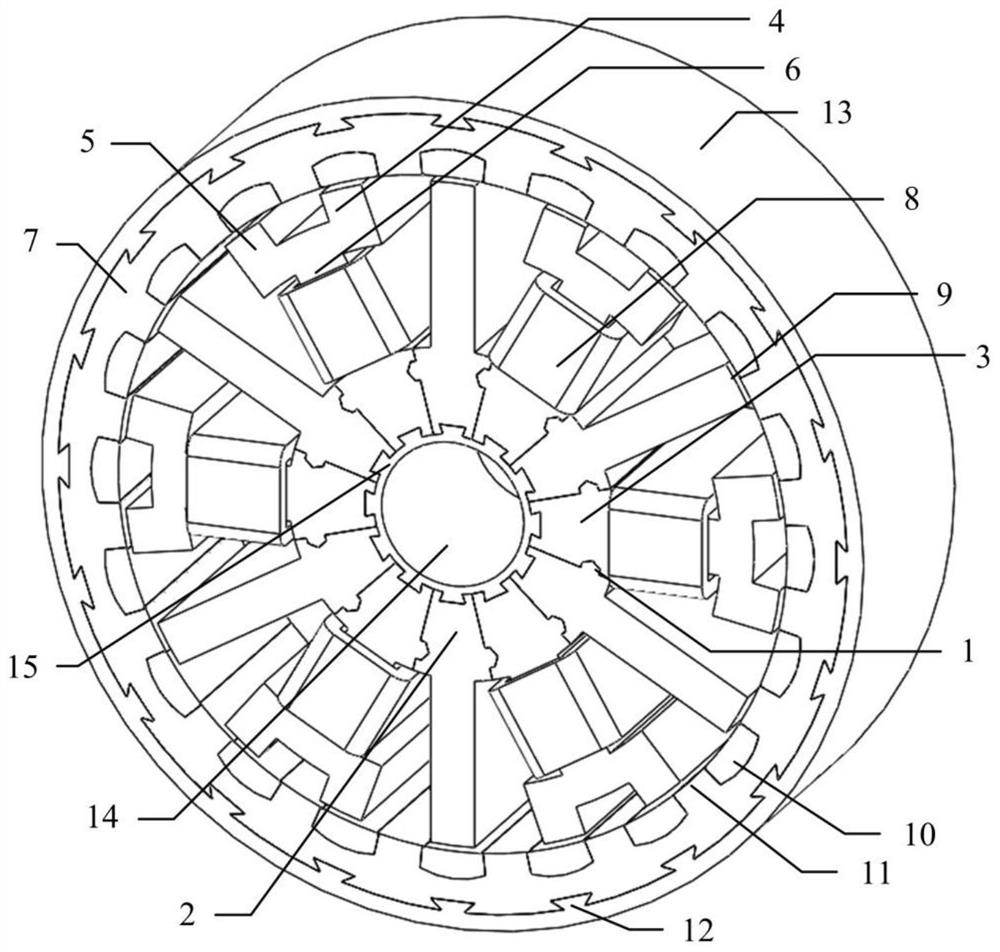

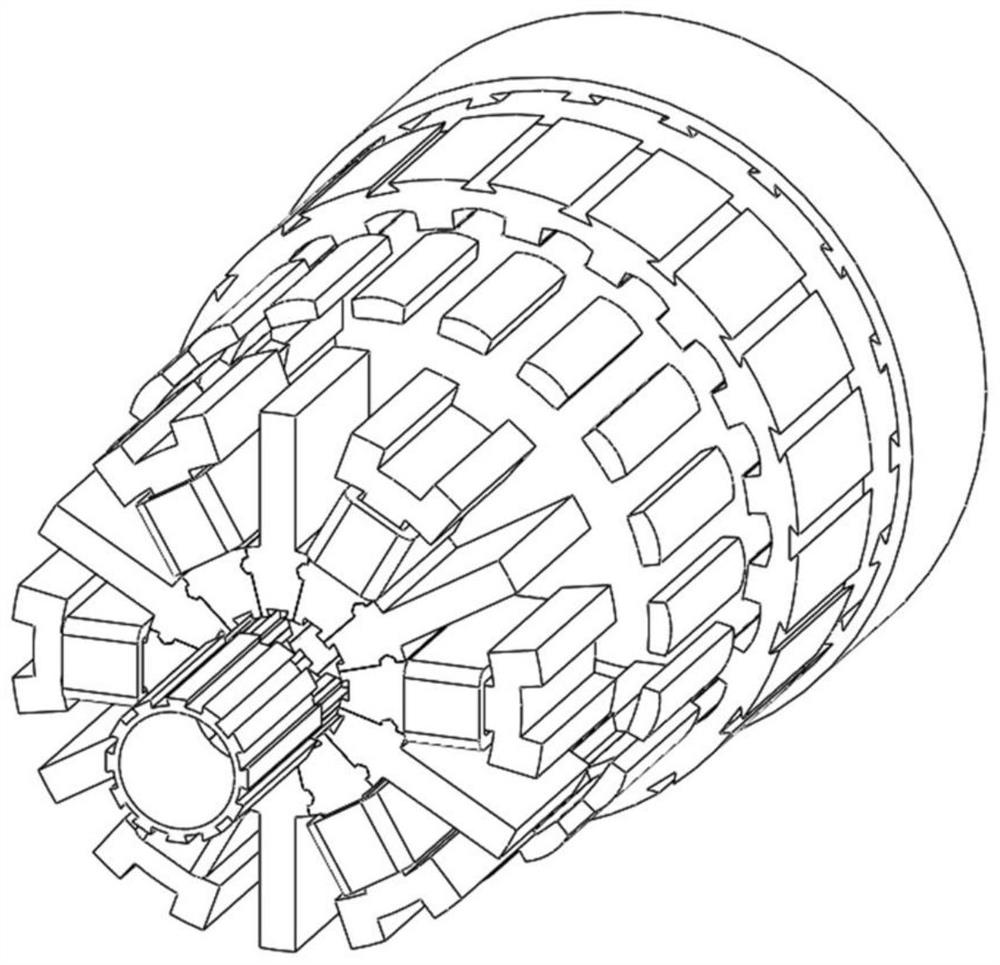

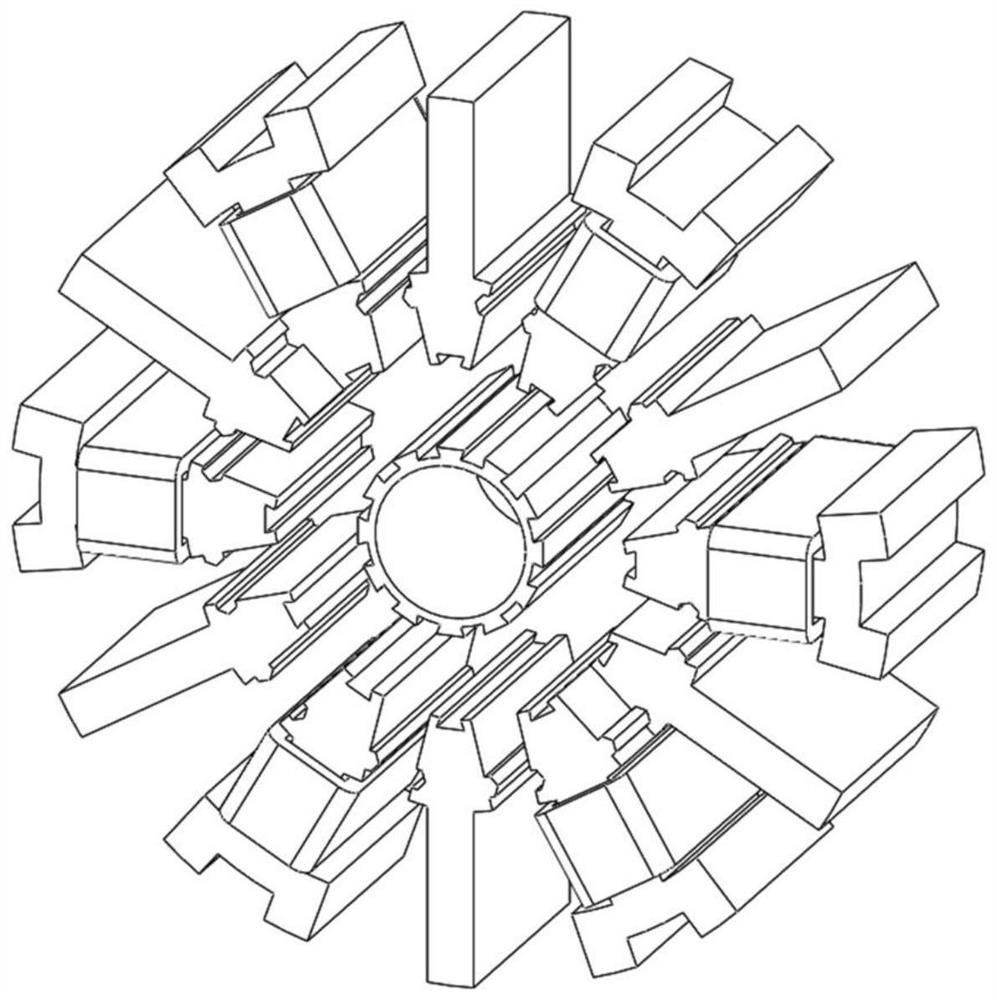

[0043] Example 1: See figure 1 A modular permanent magnet composite self-deceleration servo motor based on alternating electrode, including inner stator subtraction module 2, an internal rotor 7, an inner stator armature winding 8, an outer rotor alternating electrode magnetic steel 10 However, no magnetic aluminum case 13, the outer rotor 7 and the internal stator module are set, the rotor air gap 9, the outer rotor 7, the axis of the inner stator module, the same, outside The inner side of the rotor 7 is provided with alternating electrode magnetic steel 10, and the magnetic steel is interleaved by the rotor alternate electrode iron core electrode 11. The outer rotor 7 is opened with a dovetail groove 15 to facilitate the connection and fixation of the non-conducting aluminum shell 13. Since the non-conductive aluminum shell 13 is not magnetically angled, the original magnetic circuit will not interfere. At the same time, the structure also ensures the original electromagnetic p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com