Distributed hydrophone based on super-high bending-resistant multi-core optical fiber flexible optical cable

A multi-core optical fiber and hydrophone technology, which is used in instruments, scientific instruments, seismic signal receivers, etc., can solve problems such as inability to apply to large-scale networking applications, unstable response to external acoustic waves, and blind spots of external acoustic signals. The effect of improved sensitivity, improved sensitivity, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

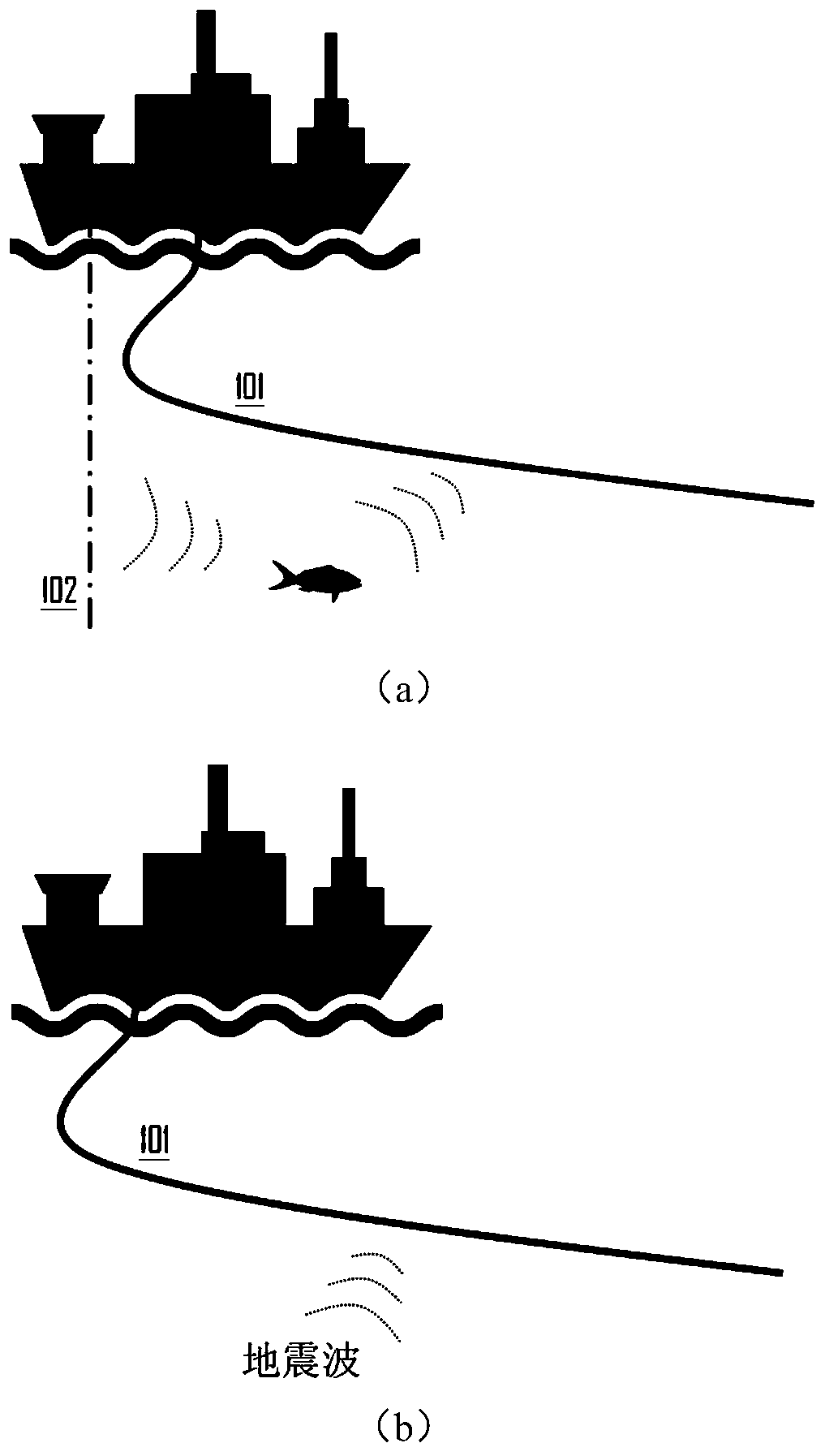

[0055] figure 1 It means that the ultra-strong bending-resistant multi-core optical fiber distributed hydrophone based on frequency division multiplexing can be divided into two parts, the first part is the main body of the distributed optical fiber hydrophone 201, and the other part is the super-strong bending resistant multi-core optical fiber flexible optical cable 101. The main body of the distributed optical fiber hydrophone 201 needs to be placed on the ship or on the shore, and the super-bending multi-core optical fiber flexible optical cable 101 needs to be towed or buried shallowly under water.

[0056] Such as figure 2 (a) and figure 2 As shown in (b), the frequency division multiplexing superbend-resistant multi-core fiber distributed hydrophone can be applied in two ways. The first application is like figure 2 As shown in (a), the underwater acoustic transducer 102 emits a sound wave of a specific wavelength. After encountering a target object, the object modulates...

Embodiment 2

[0068] Based on Example 1, the super-strong bending-resistant multi-core optical fiber flexible optical cable 101 of the present application is refined; suppose that the super-strong bending resistant multi-core optical fiber flexible optical cable 101 contains p multi-core optical fibers, and each multi-core optical fiber has q fibers core.

[0069] Figure 8 Shown here is a case where there are two multi-core optical fibers in the super-bending-resistant multi-core optical fiber flexible optical cable 101. Figure 8 (a) A schematic diagram showing the cross-section of the optical cable; Figure 8 (b) shows the longitudinal structure of the optical cable. Each multi-core optical fiber 803 in the optical cable (in this embodiment shows two multi-core optical fibers 8041 and 8042) is protected by a tight-wrapped sleeve 803 (this embodiment shows two tight-wrapped sleeves 8031 and 8032). The center of the optical cable is supported by a central support layer 802, and the material...

Embodiment 3

[0076] Based on Embodiment 1, the distributed optical fiber hydrophone 201 system combining space division multiplexing and space division multiplexing of this application is refined, and the details are as follows:

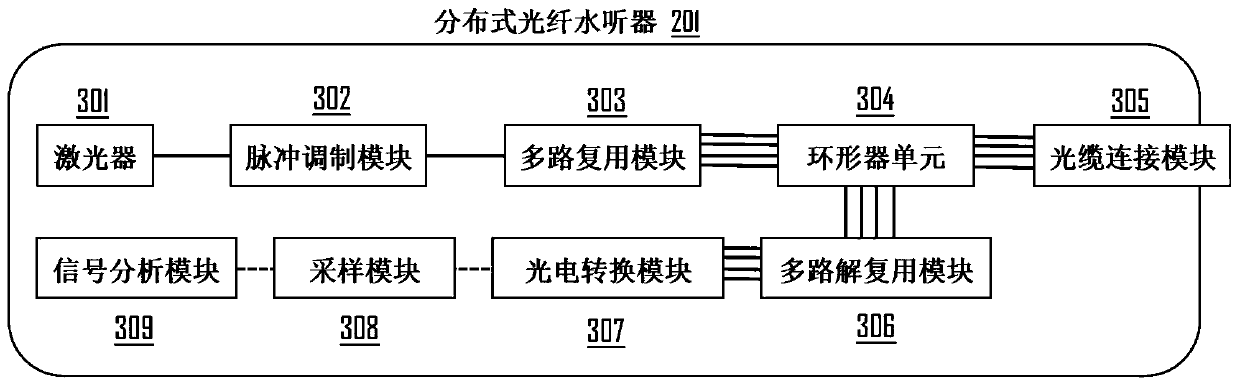

[0077] The structure of the main body of the distributed optical fiber hydrophone 201 is as image 3 Shown. The system includes a laser 301, a pulse modulation module 302, a multiplexing module 303, a circulator unit 304, and an optical cable connection module 305 that are sequentially connected using a commercial single-mode optical fiber; the 3 ports of the circulator unit 304 also use commercial single-mode The optical fiber is connected to the demultiplexing module 306 and the photodetection module 307; the output end of the photodetection module 307 is connected to the sampling module 308 and the signal analysis module 309 in sequence with electrical signal transmission lines.

[0078] The laser 301 emits a single-frequency laser with high coherence and low phase...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com