Calibration device for electronic equipment

A technology for calibrating devices and electronic equipment, applied in measuring devices, measuring electricity, measuring electrical variables, etc., can solve the problems of missed detection, wrong detection, heavy workload, etc., to improve efficiency, improve work efficiency, and save work time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

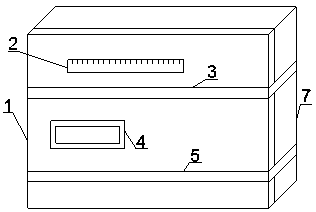

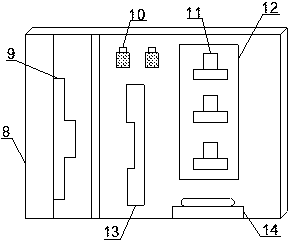

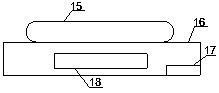

[0017] Such as Figure 1 to Figure 3 As shown, a calibration device for electronic equipment includes a box cover 1, a standard ruler 2, a rubber strip I3, an observation hole 4, a rubber strip II5, a label box 6, a box body 7, a panel 8, a bump 9, and toner 10. Weight 11, placement box 12, concave block 13, weighing device 14, weighing table 15, body 16, controller device 17 and display screen 18, box cover 1 and box body 7 form the storage box of the device , there are two through holes on the surface of the box cover 1, the standard ruler 2 and the observation hole 4 are embedded in the box cover 1, the box cover 1 and the box body 7 are fixed together by the rubber strip I3 and the rubber strip II5, and the label box 6 It is fixedly installed on one side of the box body 7, the convex block 9 is placed on the surface side of the panel 8, the two bottles of toner 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com