A gas type free piston linear engine

A gas-fired engine technology, applied to free piston engines, machines/engines, mechanical equipment, etc., can solve the problems of large ventilation loss, the inability of free piston engines to directly control the ventilation time, and insufficient ventilation process, etc., to achieve Guaranteed sufficiency, fullness, and simple overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

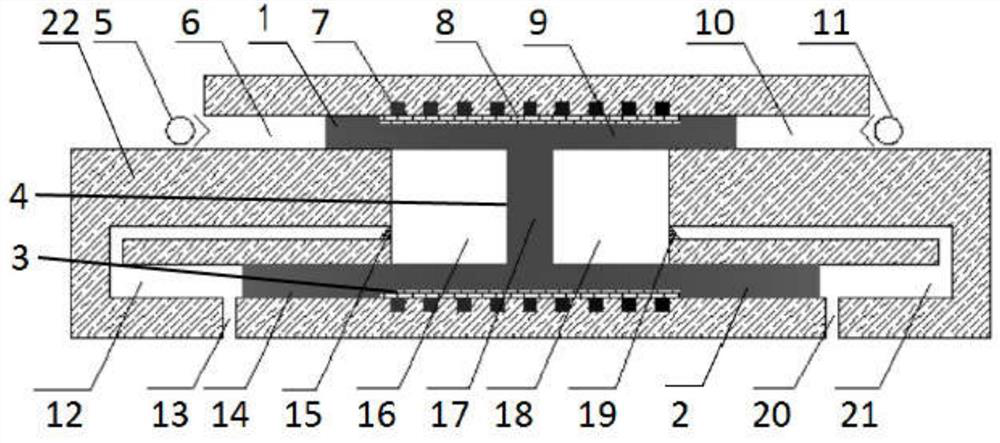

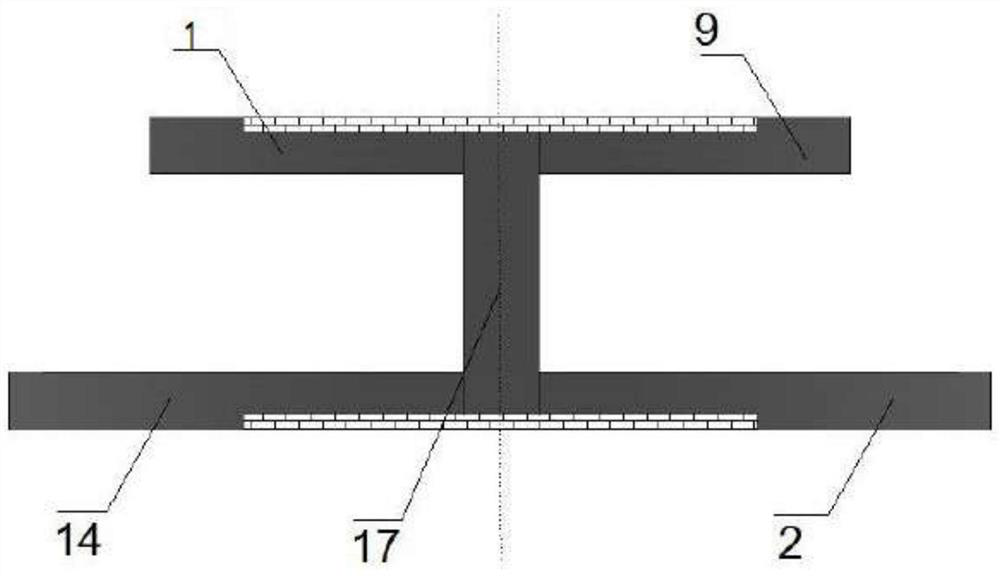

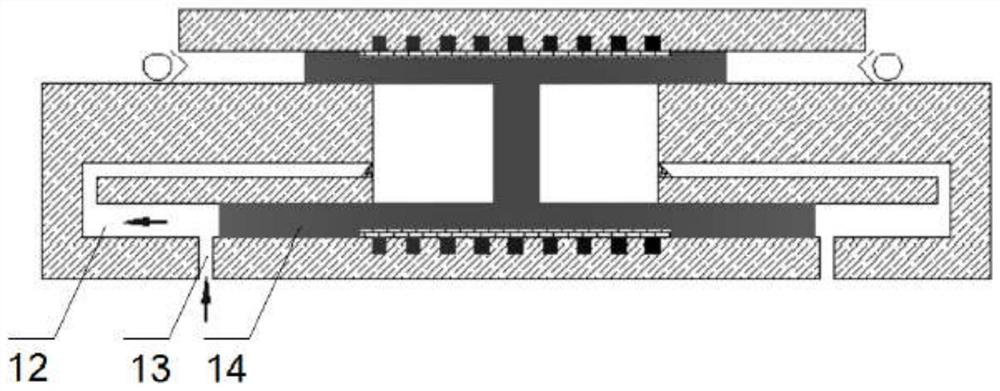

[0041] Such as figure 1 Shown is the structural representation of the present invention, as figure 2 Shown is a schematic diagram of the structure of the I-shaped piston in the present invention. Left cylinder 16 and right cylinder 18.

[0042] A gas-type free-piston linear engine, comprising an I-shaped piston 4 and a cylinder body 22;

[0043] The cylinder body 22 is a symmetrical cavity structure; the cylinder body 22 is respectively symmetrically provided with a left air intake chamber 12 and a right air intake chamber 21 and a left exhaust chamber 6 and a right exhaust chamber 10; One end and one end of the left exhaust chamber 6 communicate with the left cylinder 16 respectively; one end of the right intake chamber 21 and one end of the right exhaust chamber 10 communicate with the right cylinder 18 respectively;

[0044] The I-shaped piston 4 is installed in the cylinder body 22; the I-shaped piston 4 is a symmetrical structure, including a compression piston 17, a ...

Embodiment 2

[0073] An electrical generator comprising a gas-fired free-piston linear engine. Therefore, it has all the beneficial effects described in Embodiment 1, which will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com