Narrow edge inward opening window

A technology of inward opening windows and narrow sides, which is applied to narrow side inward opening windows. It can solve the problems of easy penetration of rainwater, reduce the aesthetics of the whole window, and the height difference between the pressure line and the pressure line, so as to achieve the effects of reducing the drop-off rate, compressing tightly, and improving the sealing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

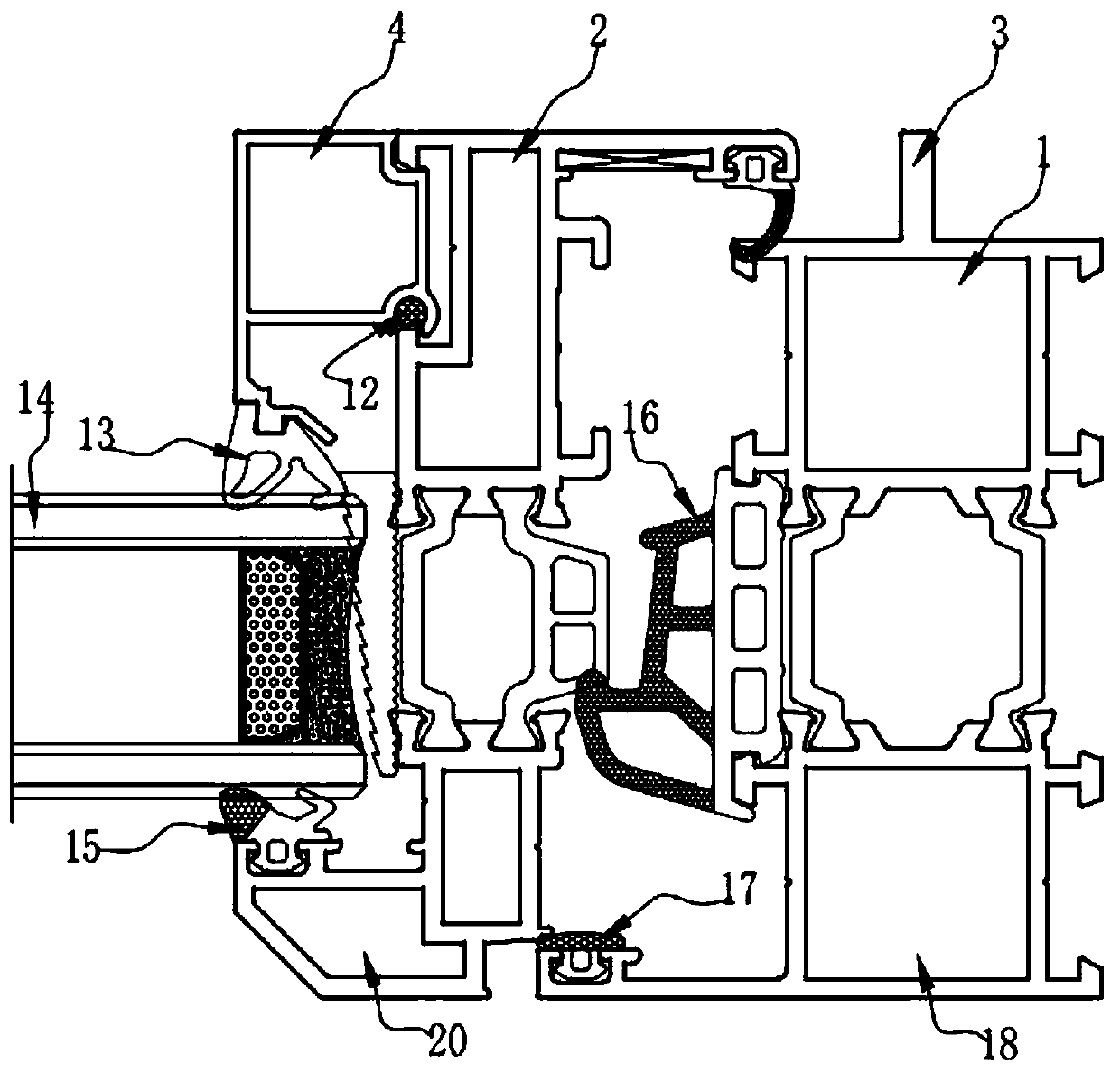

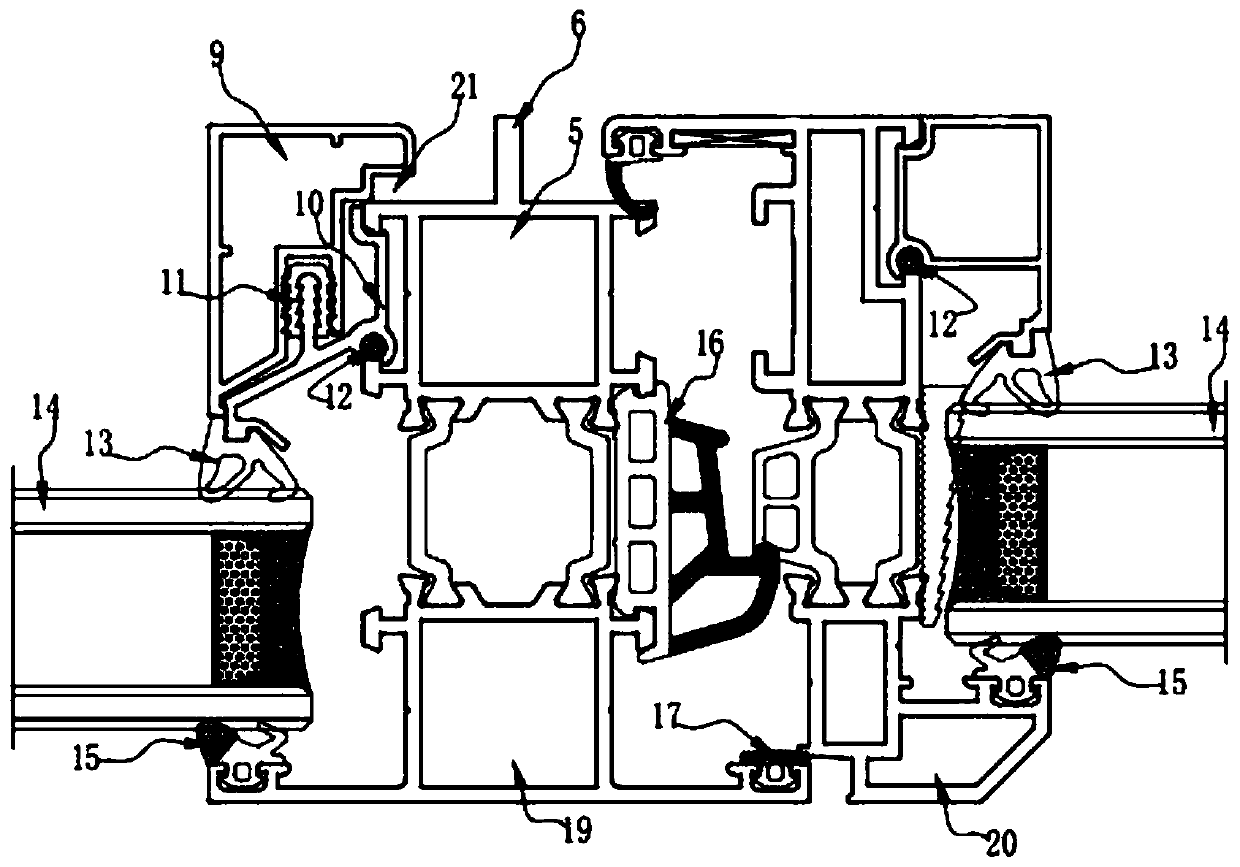

[0026] see Figure 1~2 , in an embodiment of the present invention, a narrow-sided inward-opening window includes a window frame, a stile, and a fixed pressure line. The left side of the window frame is provided with an indoor material sash 2, and the front side of the indoor material sash 2 is provided with an outdoor window. Material sash 20, the left side of the indoor material sash 2 is provided with a sash pressure line 4, the inner side of the window frame is provided with a mullion, the left side of the mullion is provided with a glass 14, and the rear side of the glass 14 is provided with a fixed pressing line. Wire.

Embodiment 2

[0028] In this embodiment, the window frame includes an indoor material frame 1, an outdoor material frame 18 and a heat insulation strip. The rear end middle part of the indoor material frame 1 is fixedly connected with a frame rib 3. The indoor surface of the frame is on the same level as the indoor material window sashes 2, which shows a flush state from the perspective of vision and sense. The position of the rib 3 of the frame will not affect the normal opening and closing of the sash.

[0029] In this embodiment, the stiles include indoor material stiles 5 and outdoor material stiles 19, and the middle part of the rear end of the indoor material stiles 5 is fixedly connected with stile ribs 6, and the stile ribs 6 are set On the top of the frame rib 3, by setting the middle stile rib 6, the strength of the whole window frame is strengthened, making the whole window more stable, the frame rib 3 strengthens the line beauty and three-dimensional effect of the window frame, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com