Double-liquid grouting reinforcement method for loose shallow covering soil

A technology of double-liquid grouting and shallow covering soil, which is applied in the fields of soil protection, construction, and infrastructure engineering, and can solve problems such as secondary leakage, affecting the reinforcement effect of covering soil, large grouting volume and grouting pressure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Embodiments of the present invention will be further described in detail below with reference to the accompanying drawings.

[0016] A double-liquid grouting reinforcement method for loose shallow overlying soil, the steps of which are as follows:

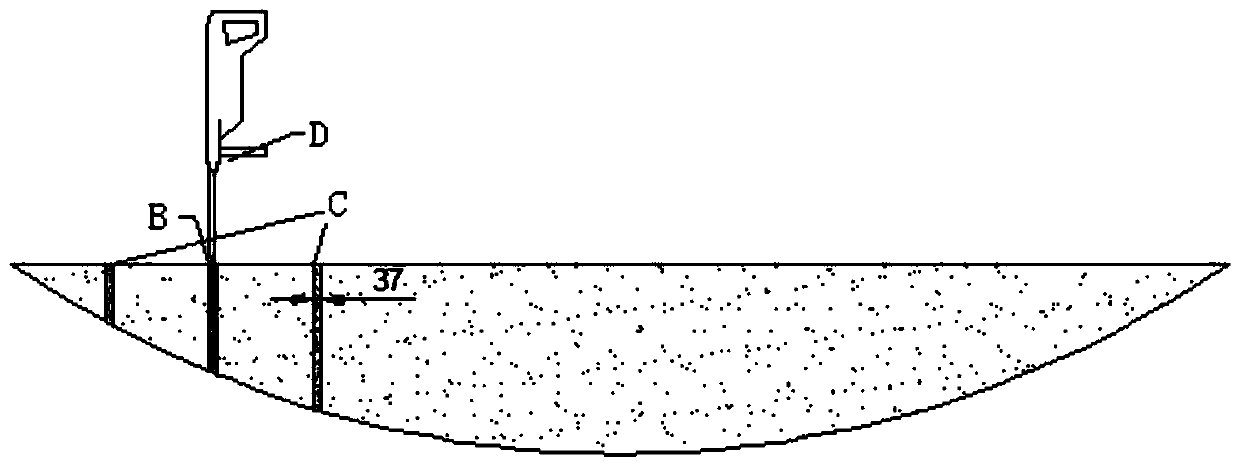

[0017] (1) Use an electric drill equipped with a 37mm diameter drill bit D to form a hole, see figure 1 , the hole forming depth is controlled within the segment, and the hole can be stopped when it reaches the inner wall of the segment, and within 1m of the grouting hole B, use an electric drill to lay out 5-10 grout holes C according to the actual situation. The hole diameter is consistent with the grouting hole B, the hole forming depth is controlled within the segment, and the hole can be stopped when it reaches the inner wall of the segment;

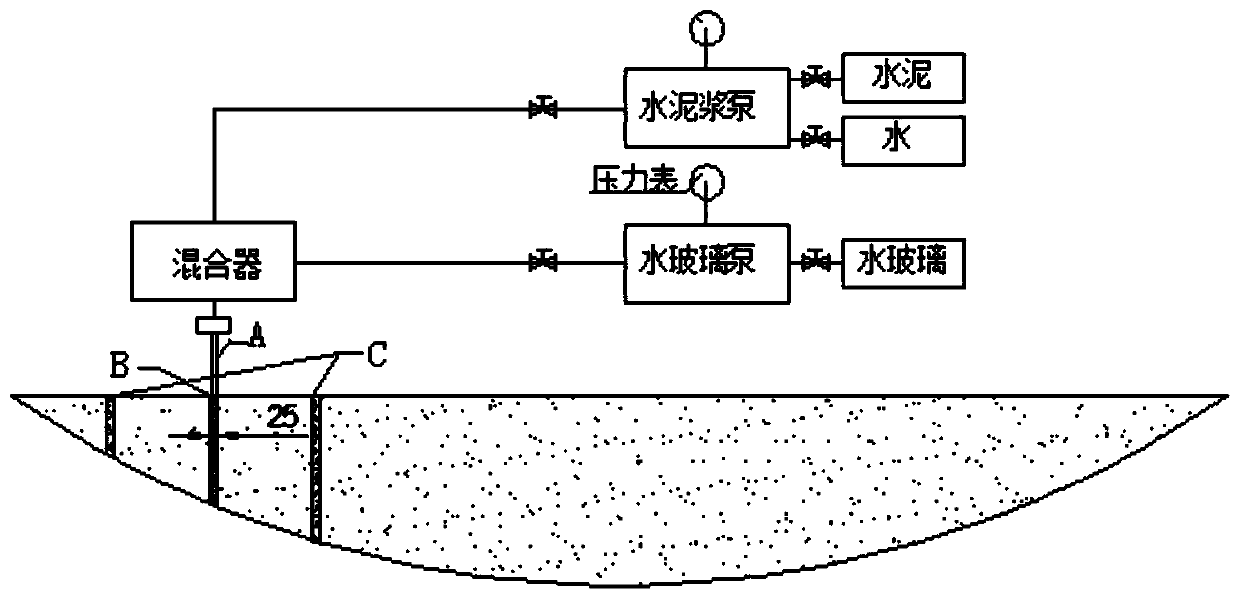

[0018] (2) The grouting pipe A adopts a 25mm diameter white iron pipe, which is inserted into the grouting hole B to the bottom of the hole, see figure 2 , Grouting hole B is b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com