Paddle stirrer with shell breaking function

An agitator and functional technology, applied in the field of biogas production, can solve the problems of increased gas production, production stop loss, low stirring efficiency, etc., and achieve the effects of reducing operating costs, strong shell breaking ability, and improving gas production rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The principles and features of the present invention will be described below with reference to the accompanying drawings. The examples are only used to explain the present invention, but not to limit the scope of the present invention.

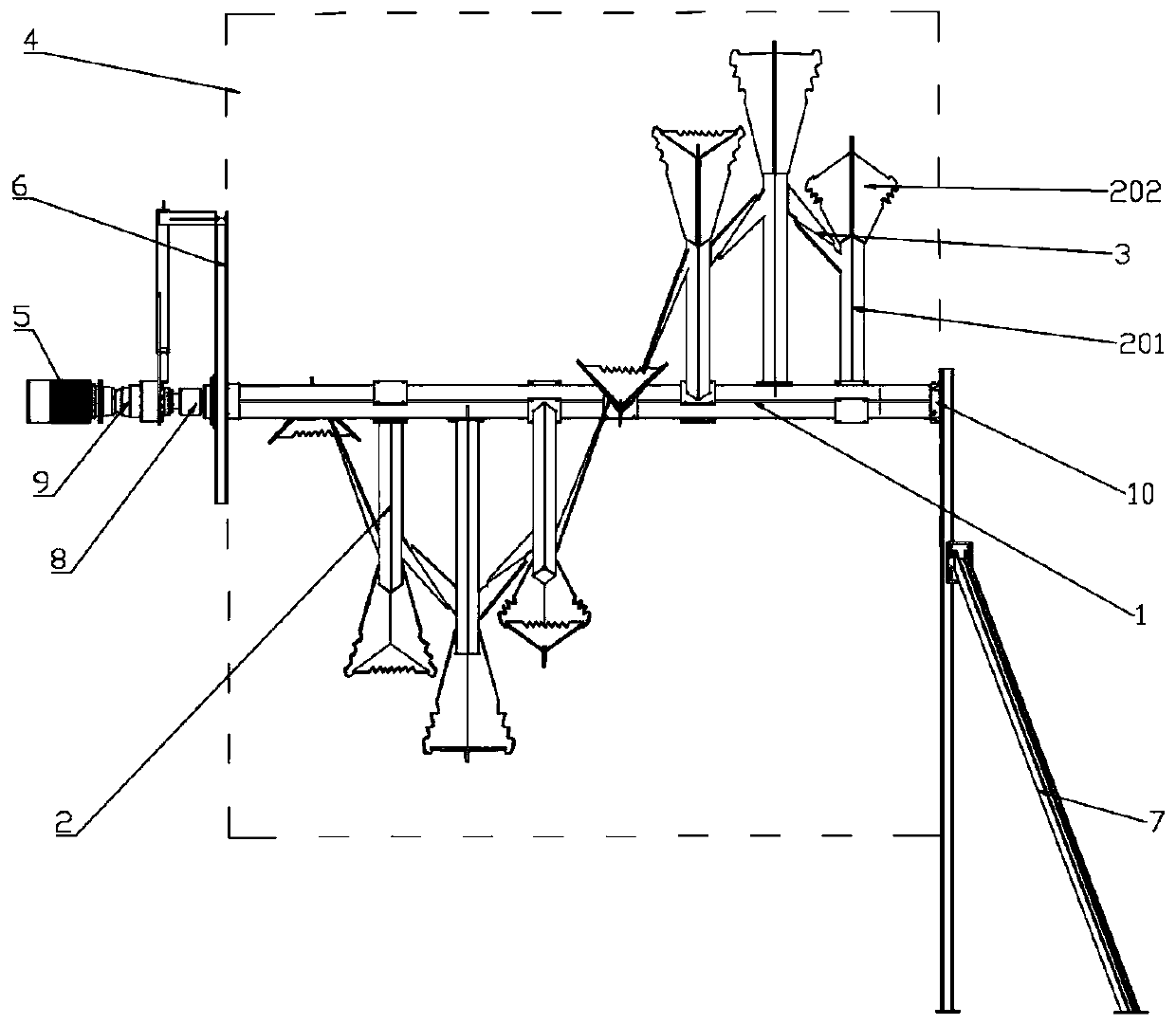

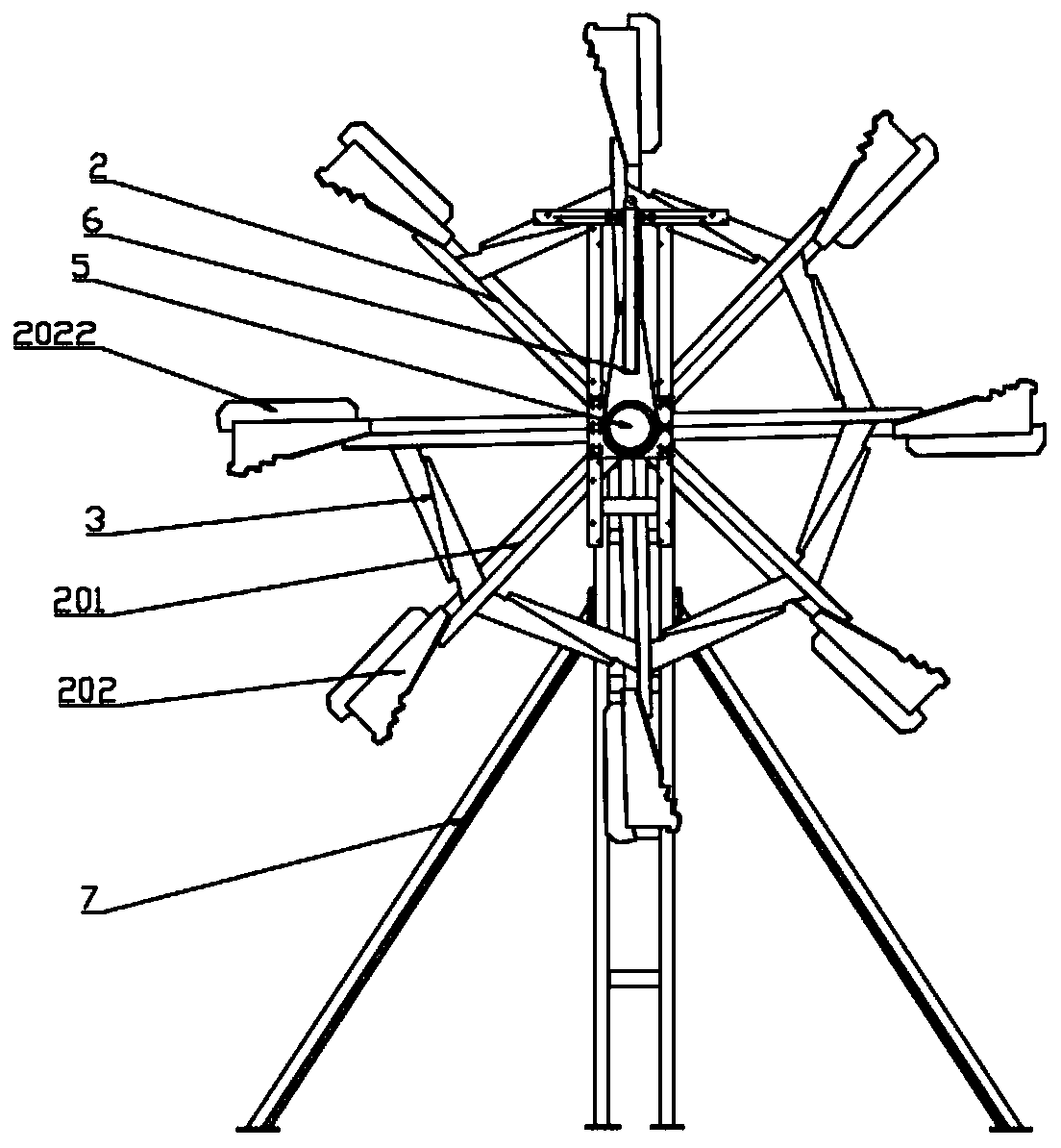

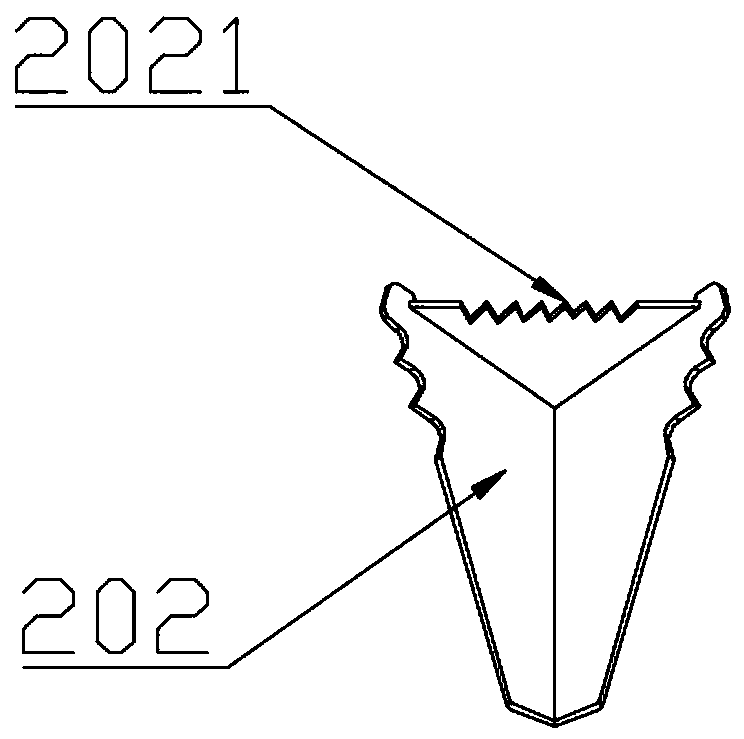

[0021] like Figure 1~2 As shown, a paddle stirrer with shell breaking function is arranged horizontally in the reactor 4 and includes a rotating shaft 1 and a stirring paddle 2 connected to each other. The stirring paddle 2 is arranged perpendicular to the rotating shaft 1 . Both ends of the rotating shaft 1 traverse the wall of the reactor 4, and the interface between the rotating shaft 1 and the reactor 4 is sealed by a mechanical sealing device 10, and the rotating shaft 1 and the reactor 4 can rotate relatively. The mechanical sealing device 10 is a prior art, and the present embodiment will not be repeated here. One end of the rotating shaft 1 is provided with a coaxial bidirectional drive motor 5, the output shaft of the driving...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com