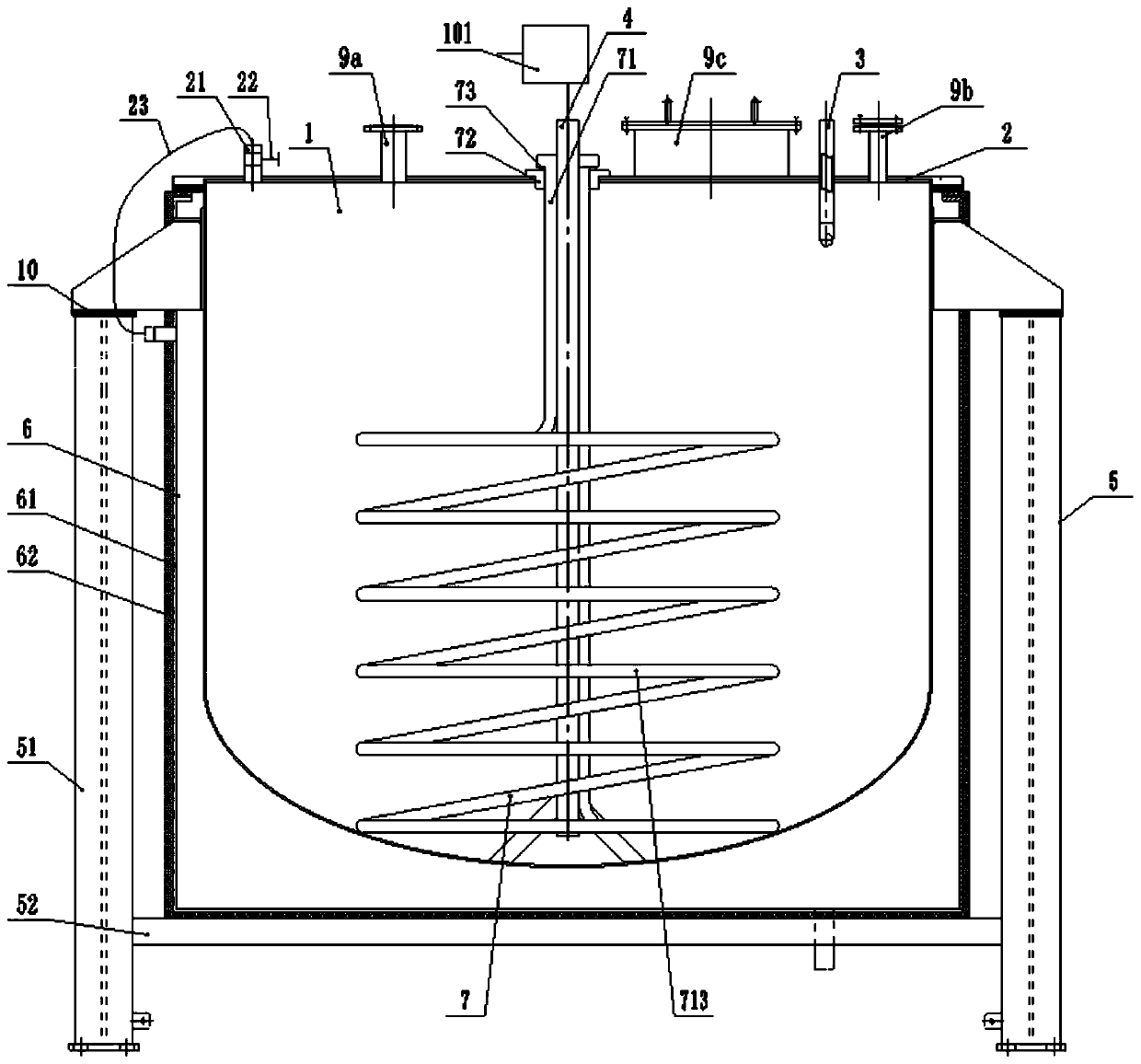

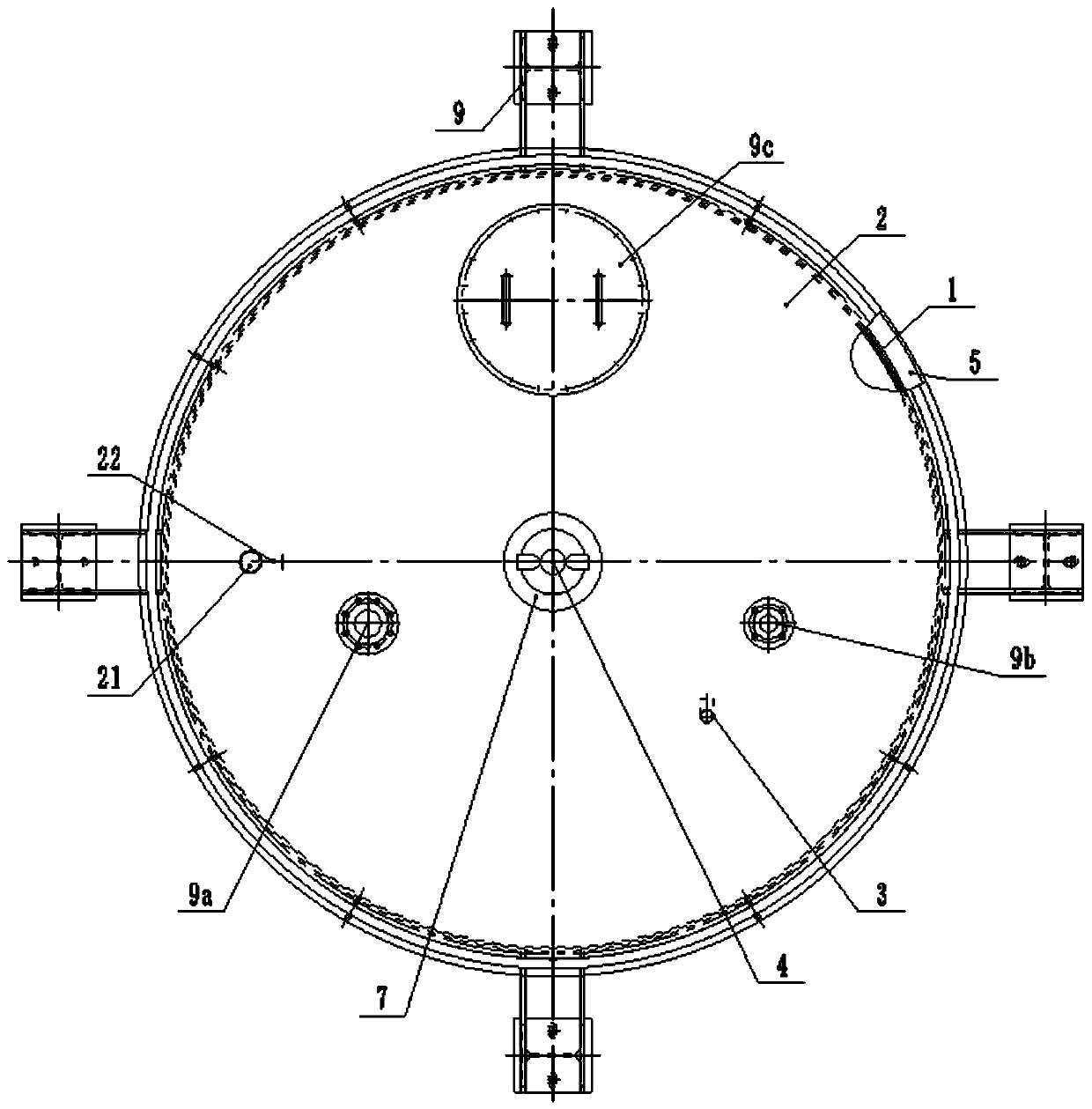

Novel alkali liquor buffer tank

A buffer tank and lye technology, which is applied in the field of solid alkali or caustic soda industry, can solve the problems of the loss of heat in the tank, save energy consumption, increase production costs, energy waste, etc., and achieve energy saving, heat loss, and heat reduction. the drain effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

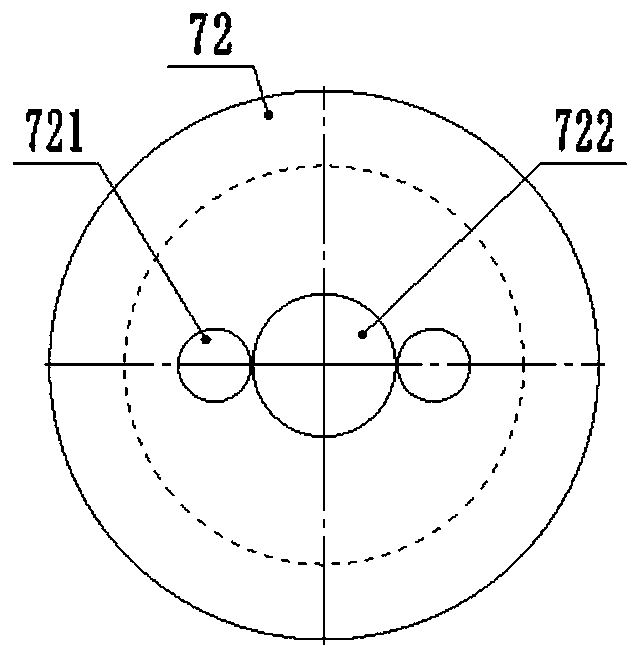

[0043] There is a perforation 722 suitable for the liquid outlet pipe on the fixing seat at the midpoint between the two through holes, and the perforation is used for the connection and fixing of the liquid outlet pipe; when the heating pipe and the liquid outlet pipe are installed, the inlet section and the outlet section It is fixed side by side with the liquid outlet pipe, so that the liquid outlet pipe and the heating pipe are connected together, and the heating pipe can ensure the temperature of the liquid outlet pipe, so as to avoid the molten lye in the liquid outlet pipe due to the temperature drop and solidification of the liquid outlet pipe. In the case of blockage or obstruction of the extraction of molten lye, the structure and layout are more compact and reasonable.

[0044] As a preferred embodiment:

[0045] Combined with the drawings in the description, the middle section is in the shape of a helical spring, which can realize heating in a larger range or area,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com