Plastic woven bag stitch removing equipment

A technology of plastic woven bags and equipment, applied in thin material handling, transportation of filamentous materials, packaging, etc., can solve the problems of high cost, poor working conditions, low efficiency of manual unwinding, etc., to avoid damage and avoid sliding. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

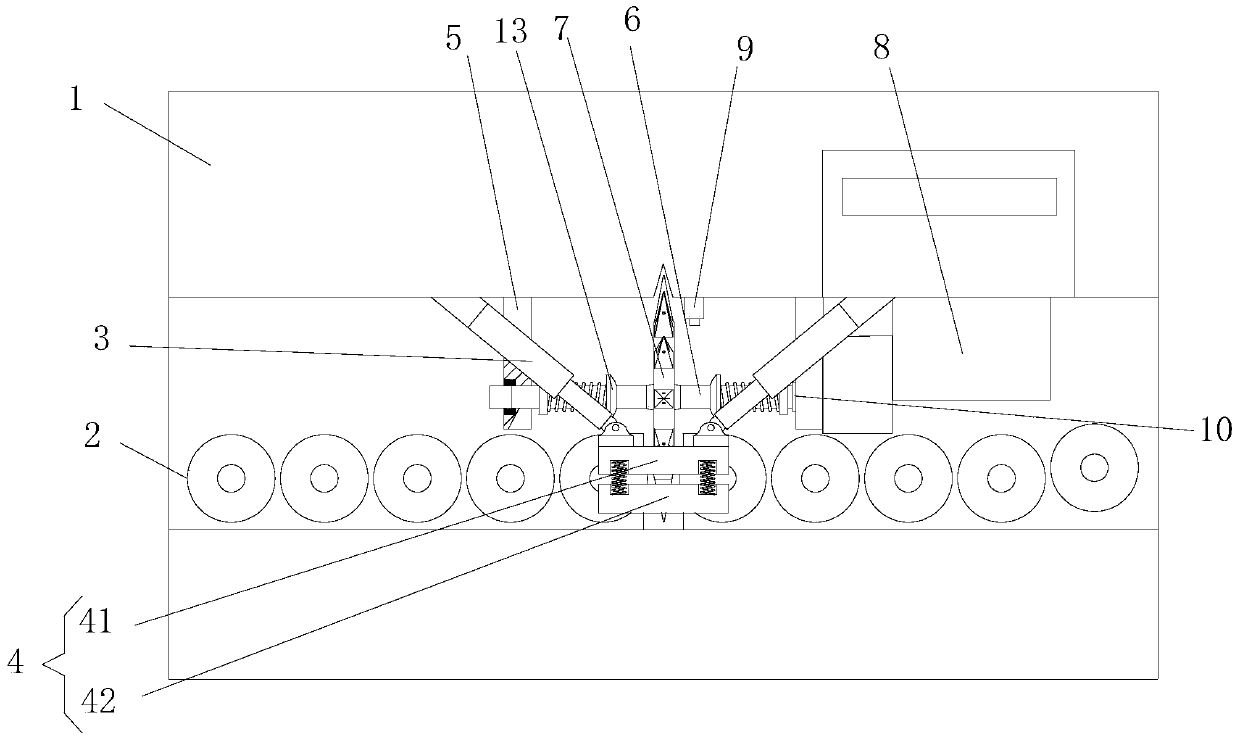

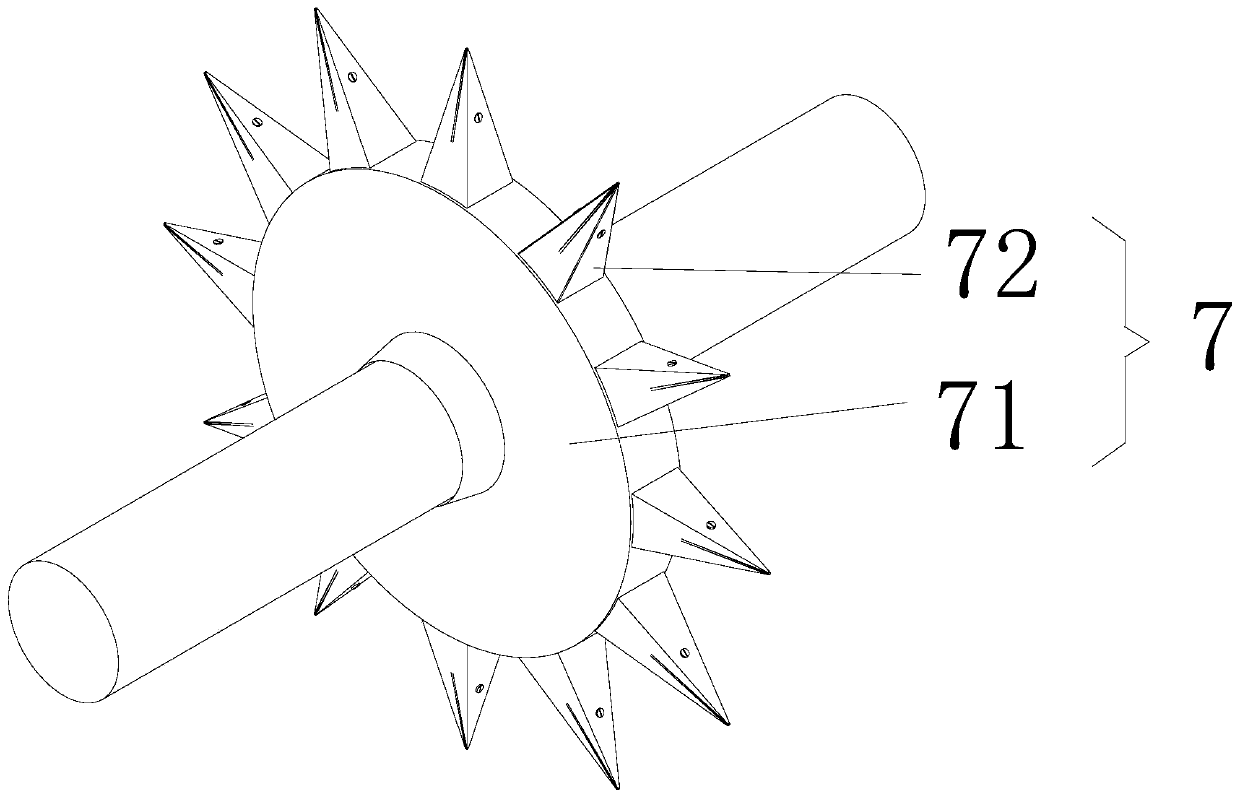

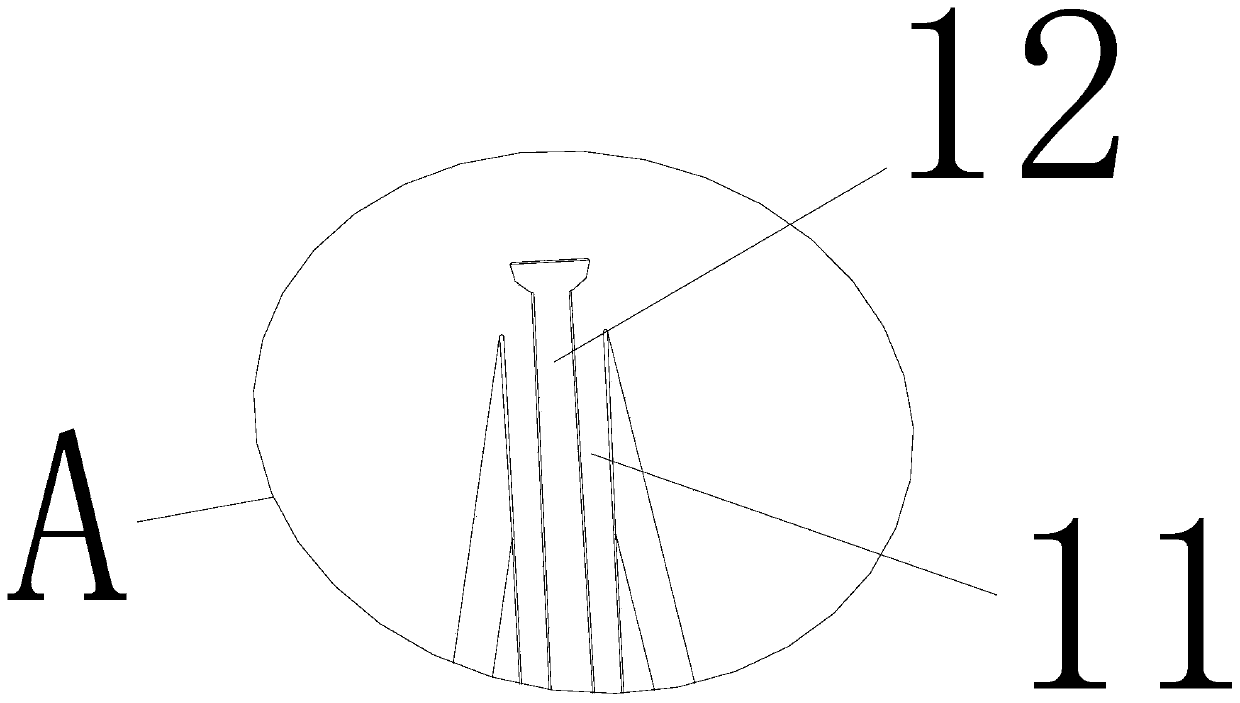

[0021] Such as Figure 1-3 As shown, a plastic woven bag thread removal equipment includes a machine base 1, a conveyor belt mechanism is provided at the bottom of the inner surface of the machine base 1, and a plurality of transmission rollers 2 are provided at a position close to the bottom of the inner surface of the machine base 1 on the back of the inner surface of the machine base 1 , and the transmission roller 2 is driven by the drive motor, belt and pulley arranged inside the base 1, the top of the inner surface of the base 1 is close to the front of the transmission roller 2 and the symmetrical position near the middle of the base 1 is provided with an electric telescopic rod 3, the motorized The ends of the telescopic rods 3 that are cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com