Fixing device for machining automobile beam middle plate

A technology of automobile girders and fixing devices, which is applied to workbenches, manufacturing tools, coil springs, etc., can solve problems such as inconvenient operation and impact on production efficiency, and achieve the effects of convenient operation, high practicability, and good lighting effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

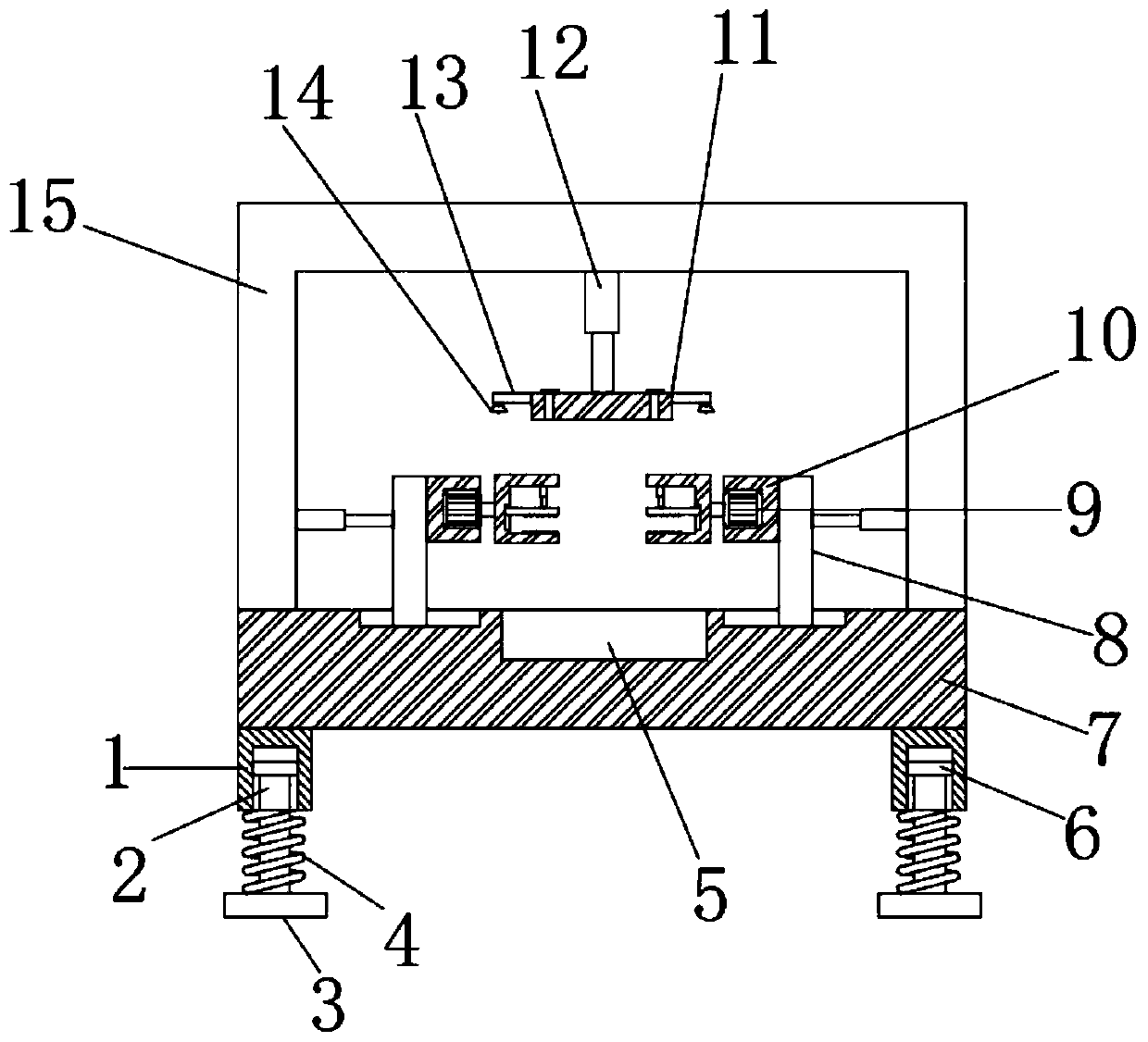

[0026] refer to Figure 1-3 , a fixing device for the processing of the middle plate of the automobile beam, including a workbench 7, the same gantry 15 is fixed by screws on both sides of the top outer wall of the workbench 7, and the inner wall on the opposite side of the gantry 15 is fixed by electric pushers. One end of the electric push rod piston rod is fixed with a sliding plate 8 by a screw, and the outer wall of the sliding plate 8 is fixed with a fixed block 10 by a screw, and the outer wall of one side of the fixed block 10 is provided with a mounting groove, and the inner wall of the mounting groove is fixed by a screw. The motor 9 is fixed, the output shaft of the motor 9 is connected with a U-shaped plate 16 through a coupling, and the top inner wall of the U-shaped plate 16 is fixed with a hydraulic rod 17 by screws, and one end of the piston rod of the hydraulic rod 17 is fixed with a fixed plate by screws 18.

[0027] In the present invention, the bottom inne...

Embodiment 2

[0034] refer to figure 1 , a fixing device for processing the middle plate of the automobile beam. Compared with Embodiment 1, this embodiment also includes that the outer walls on both sides of the mounting plate 11 are fixed with lamp panels 13 by screws, and the bottom outer walls of the lamp panels 13 are fixed by screws. There are illuminating lamps 14 .

[0035] The illuminating lamp 14 can play a good lighting effect, is convenient to turn on and use when the optical fiber is weak, and is convenient for workers to find the processing position.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com