A robot welding device and a method for obtaining welding seam trajectory

A technology of robot welding and acquisition method, applied in welding equipment, welding equipment, auxiliary devices, etc., can solve the problem of low requirements for operators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention can be explained in detail through the following examples, and the purpose of disclosing the present invention is to protect all technical improvements within the scope of the present invention.

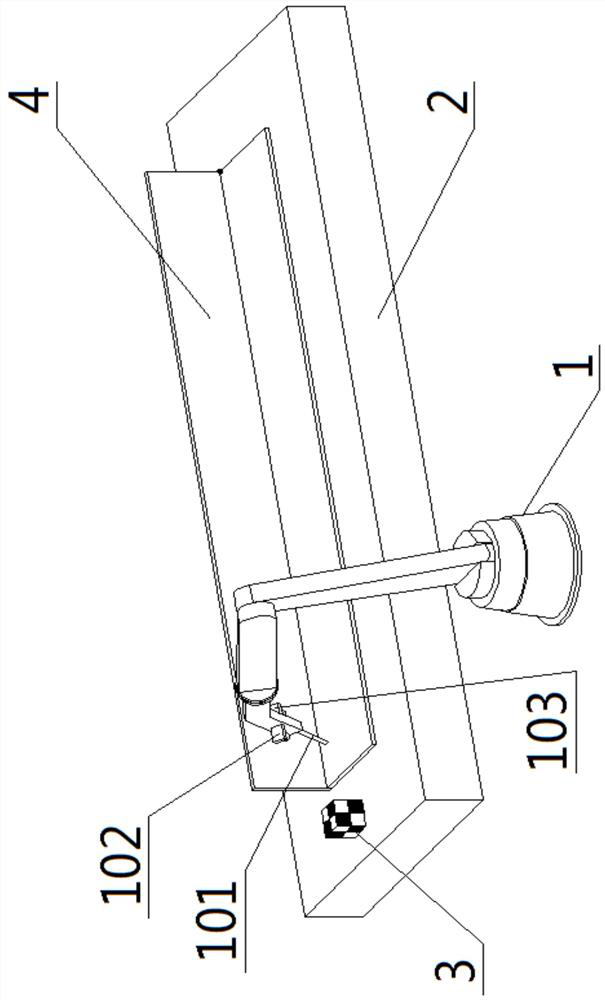

[0027]A robot welding device, comprising a welding robot 1, an XY workbench 2, a calibration reference block 3, and a computer; the welding robot 1 is fixedly arranged at the front of the XY workbench 2, and the welding robot 1 and the XY workbench 2 are linked by computer control Movement; the welding robot 1 includes a welding torch 101, a camera 102, and a 3D scanner 103 fixedly arranged on the mechanical arm; the lens axis of the camera 102 is parallel to the wire feeding hole axis of the welding torch 101; the 3D scanner 103 is a laser 3D scanner; the plane where the axes of the 3D scanner 103 laser emitting lens and the two laser receiving lenses are located is parallel to the axis of the wire feeding hole of the welding torch 101, and perpendicular ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com