Core-shell structure powder fire extinguishing medium and preparation method and application thereof

A technology of fire extinguishing medium and core-shell structure, which is applied in the direction of fire prevention equipment, etc., can solve the problems of being unable to effectively block the contact between the fuel liquid surface and the air, difficult cooling effect and chemical fire extinguishing effect, and no covering fire extinguishing effect, so as to achieve good reburning , good versatility, and the effect of increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

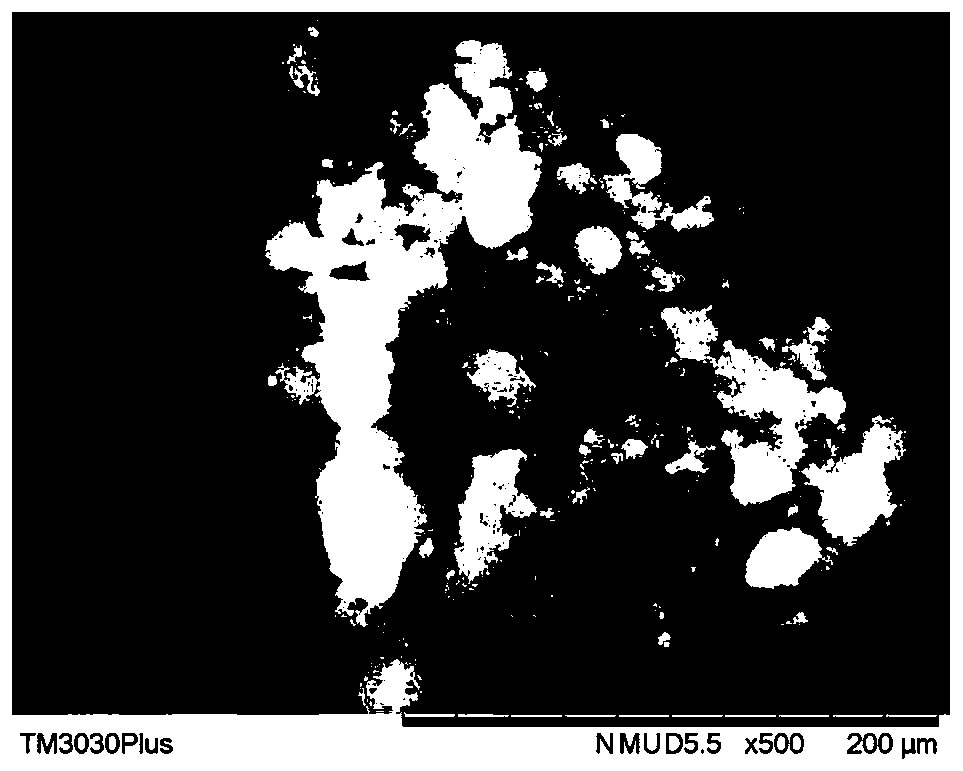

Image

Examples

Embodiment 1

[0045] In this example, the core-shell structure powder fire extinguishing medium is prepared from water, potassium nitrate, silicon dioxide, sodium alginate and methyl hydrogen-containing silicone oil with high hydrogen content, and the mass percentage of each raw material is:

[0046]

[0047] The preparation method is:

[0048] At room temperature, pour potassium nitrate into water and stir until completely dissolved, then add sodium alginate and stir evenly;

[0049] Pour the above liquid into the mixing container of a high-speed mixer, add silicon dioxide and high hydrogen-containing methyl hydrogen silicone oil in sequence, and continuously stir for 30 seconds at a speed of 15,000 r / min to obtain a core-shell structure powder fire extinguishing medium.

Embodiment 2

[0051] The preparation method is basically the same as in Example 1, except that the preparation raw materials and their mass percentages are:

[0052]

Embodiment 3

[0054] The preparation method is basically the same as in Example 1, except that the preparation raw materials and their mass percentages are:

[0055]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com