Coil for a magneto

A magneto and coil technology, applied in electromechanical devices, electrical components, electric components, etc., can solve problems such as waste of stator core or local coil support, damage to insulator or coil support, and difficulty in re-use, etc., to improve the utilization rate, Prevent waste and improve the effect of stable installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

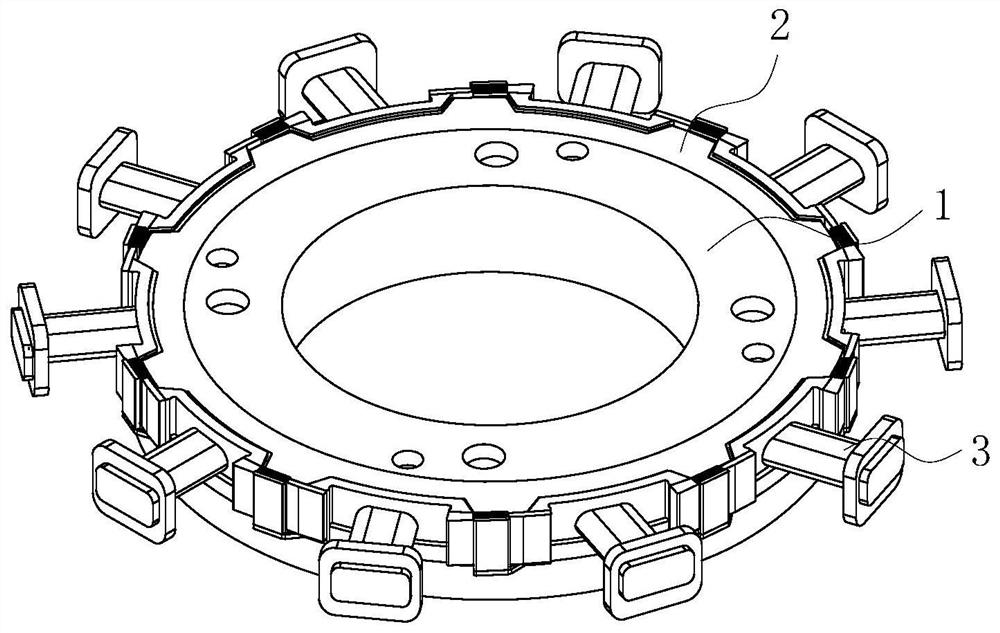

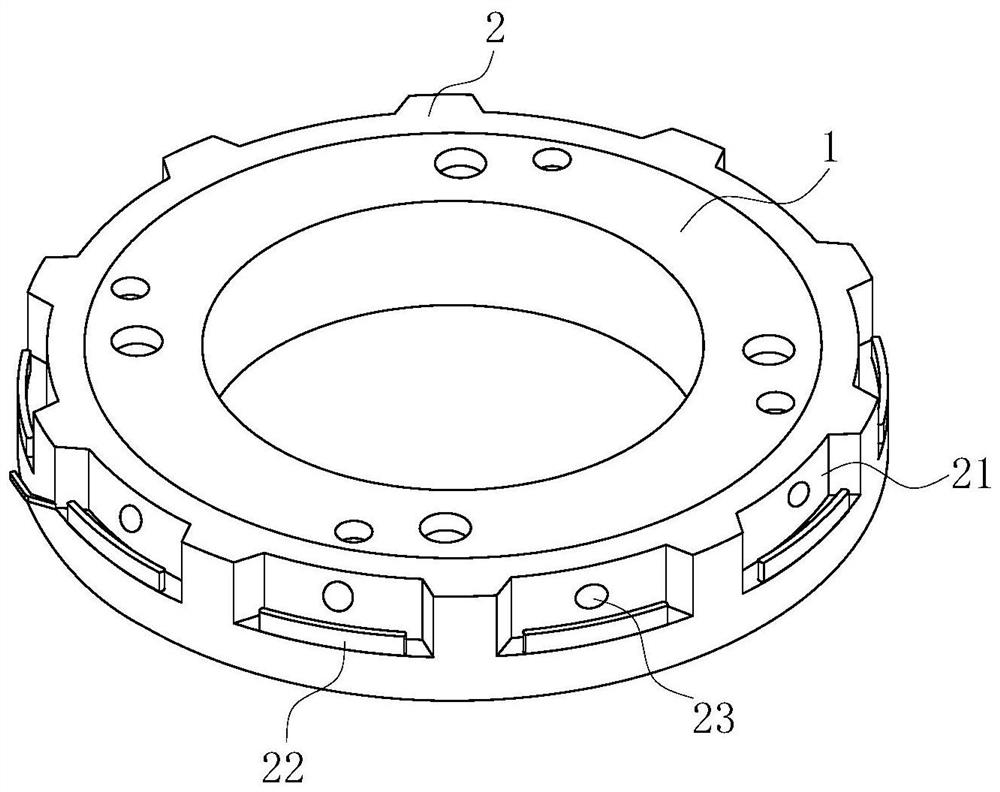

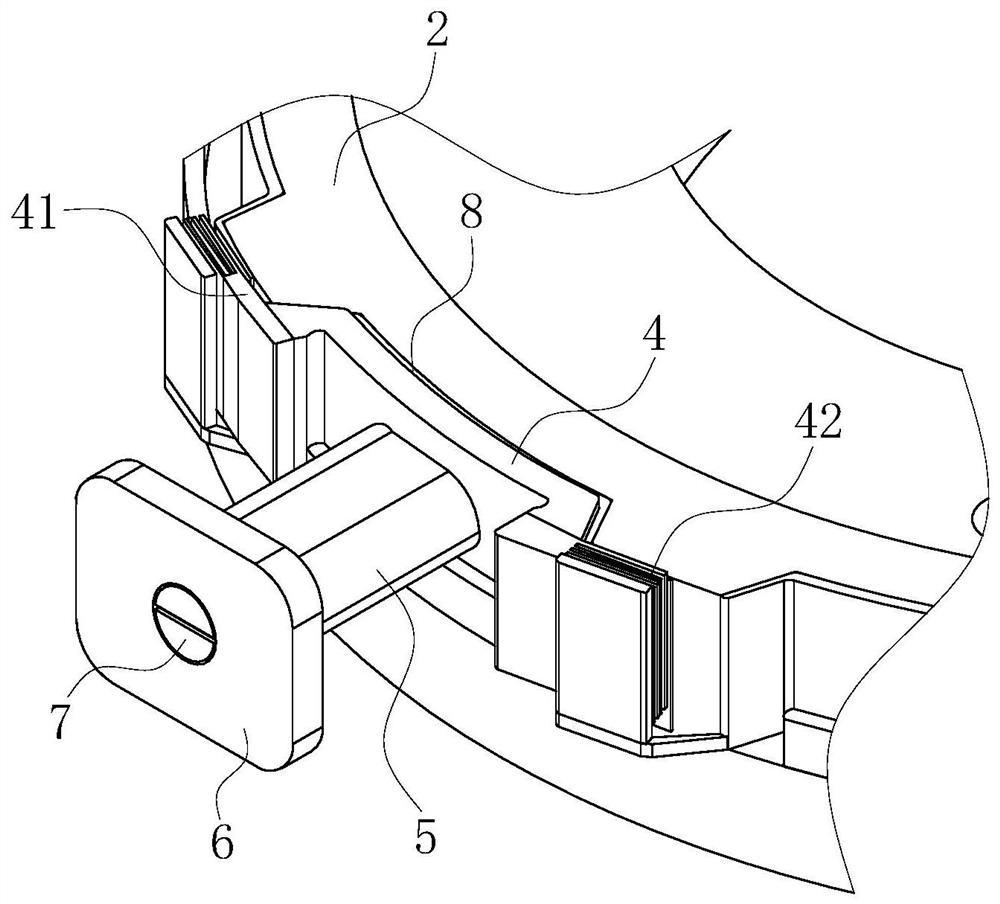

[0022] use Figure 1-Figure 5 A coil for a magneto according to an embodiment of the present invention will be described below.

[0023] like Figure 1-Figure 5As shown, a coil for a magnetic motor according to the present invention includes a stator core 1, an insulating layer 2 and a coil support 3; the outside of the stator core 1 is wrapped with an insulating layer 2, and on the outer wall of the insulating layer 2 A plurality of engaging grooves 21 are uniformly opened; elastic engaging pieces 22 are arranged in the plurality of engaging grooves 21, and threaded holes 23 are provided on the inner walls of the plurality of engaging grooves 21; the coil support 3 is provided with It is made of high temperature resistant insulating rubber material, and the coil support 3 includes an elastic engaging plate 4, a winding post 5 and a baffle plate 6; the elastic engaging plate 4 is engaged and installed between the engaging groove 21 and the elastic engaging piece 22, and The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com