Cement free calcium soft measurement method based on non-supervision and supervision learning

A supervised learning and unsupervised technology, applied in the field of industrial cement quality soft sensor monitoring, can solve problems such as overfitting, and achieve the effect of improving cement clinker quality, reducing production energy consumption, and large time lag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing, the present invention is described in further detail:

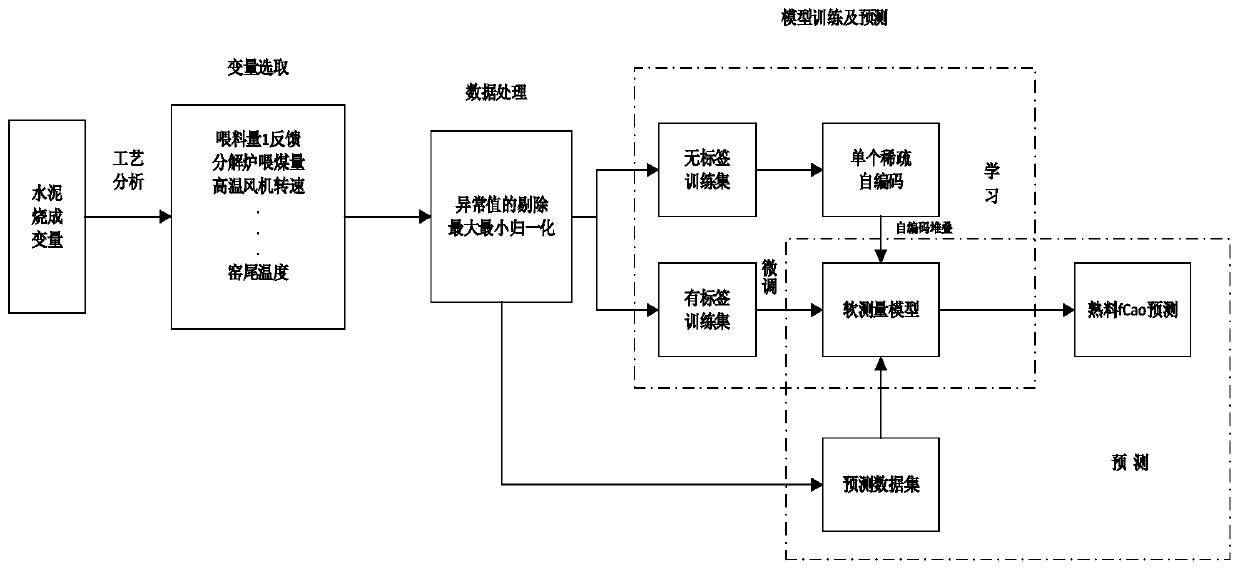

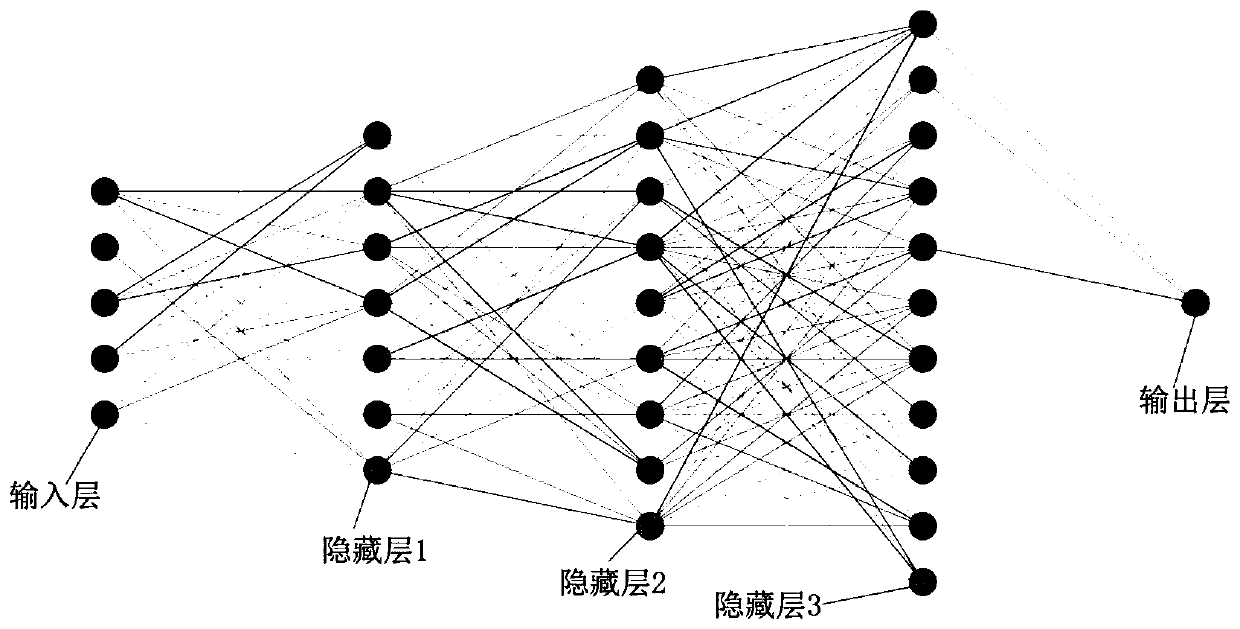

[0019] The present invention proposes a cement free calcium soft measurement method based on unsupervised and supervised learning. The core is a specially designed depth autoencoder, and a three-hidden layer is designed in combination with the characteristics of sparse autoencoder and complete autoencoder. The stacked (depth) asymmetric sparse complete auto-encoder (Sparse Complete Auto-encoder, referred to as SC-AE), such as image 3 As shown, structurally, multiple hidden layers are used to improve the feature extraction ability of single hidden layer. The structure block diagram of soft sensor is as follows: figure 1 As shown, the variable selection is performed first, and then the outlier processing and normalization processing are performed on the sample set, and the training sample set and the prediction sample set are selected, wherein the training sample set ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com