Feed screw nut pair, safety transmission device and lifting mechanism

A technology of screw nut pair and driving device, which is applied in the direction of transmission device, hoisting device, mechanical equipment, etc., can solve problems such as damage, unsafe transmission mechanism, deformation of screw nut pair, etc., and achieve the effect of avoiding head-to-head

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] see Figure 4 to Figure 7 , A preferred embodiment of the present invention discloses a screw nut pair, which includes a screw 1, a nut 2 and a protection mechanism.

[0038] see Figure 4 and Figure 5 , the nut 2 is provided with a screw hole 21 , the screw 1 is penetrated in the screw hole 21 , and the nut 2 can slide back and forth along the axial direction of the screw 1 .

[0039] see Figure 6 and Figure 7 , the protection mechanism is arranged in the screw hole 21 of the nut 2 , and the protection mechanism includes a mounting hole 22 , a spring 23 and a marble 24 .

[0040] The mounting hole 22 is opened in the screw hole 21, and the mounting hole 22 is facing the outer surface of the screw rod 1, the spring 23 and the marble 24 are all accommodated in the mounting hole 22, and the spring 23 is used to provide an elastic force, so that the marble 24 extends out of the installation hole 22 and then resists in the threaded groove of the screw rod 1 .

[00...

Embodiment 2

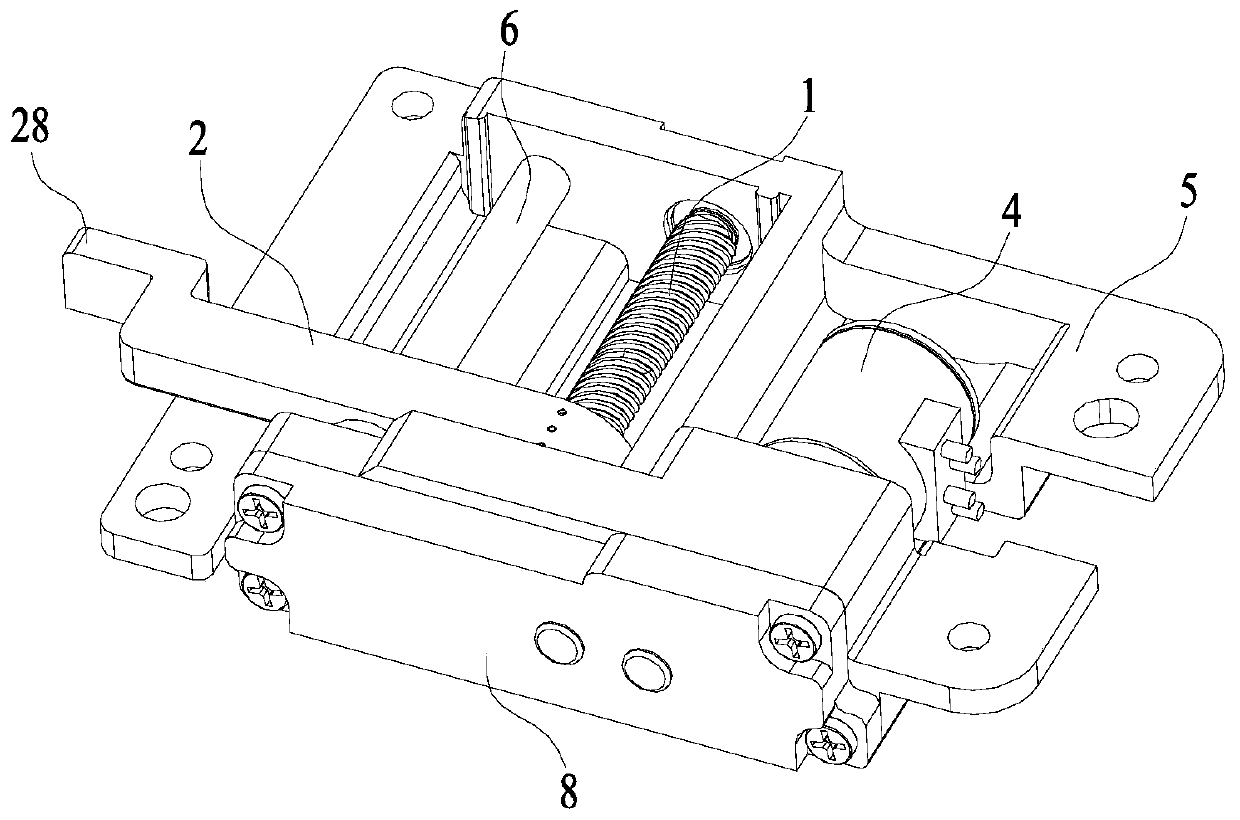

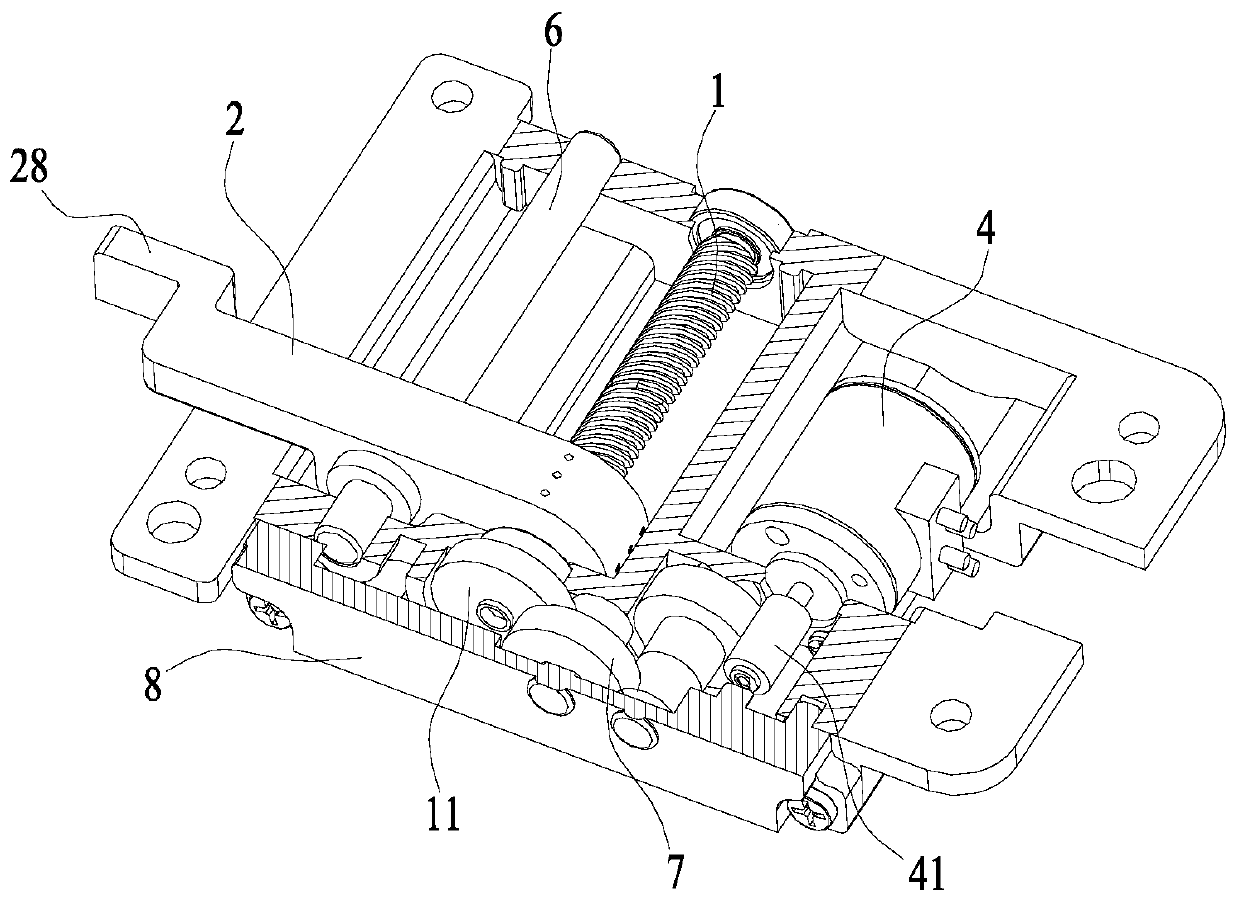

[0055] see Figure 1 to Figure 7 , This embodiment discloses a safety transmission device, which includes a driving device, a transmission assembly 7 and a screw nut pair, and the screw nut pair is the screw nut pair described in Embodiment 1. In this embodiment, the driving device is a driving motor 4 .

[0056] The transmission assembly 7 is installed between the drive motor 4 and the screw nut pair, and is connected to the drive motor 4 and the screw nut pair respectively.

[0057] Specifically, in one of the embodiments, the transmission assembly 7 is composed of a plurality of gears meshed with each other, and the plurality of gears are meshed with the driving motor 4 and the screw 1 respectively. Specifically, the rotating shaft of the driving motor 4 is fixedly connected with a driving gear 41 , and the driving end of the screw 1 is fixedly connected with a driving gear 11 .

[0058] In some other embodiments, a gearbox is provided between the drive motor 4 and the sc...

Embodiment 3

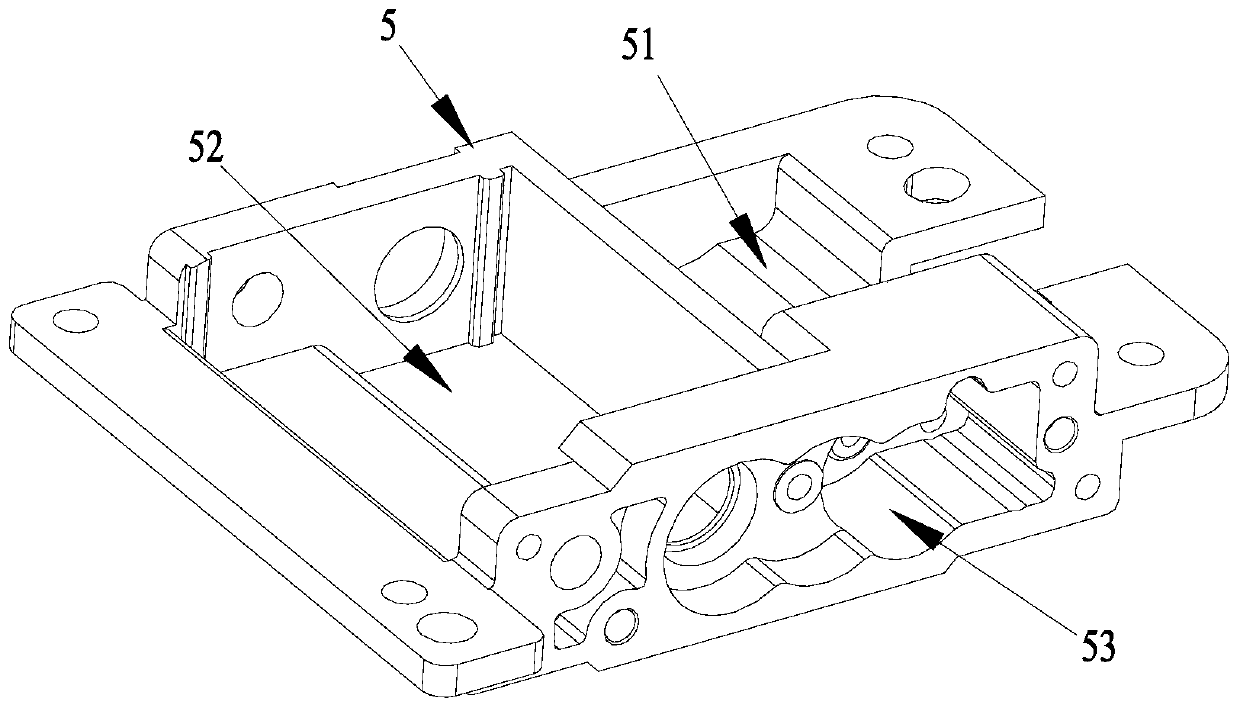

[0066] see Figure 1 to Figure 7 , this embodiment discloses a lifting mechanism, which includes a shell base 5 and a safety transmission device, the safety transmission device is the safety transmission device described in Embodiment 2, and the safety transmission device further includes a drive motor 4, a transmission assembly 7 and the screw nut pair described in Embodiment 1.

[0067] see image 3 , the safety transmission device is installed on the housing base 5, which is specifically implemented in this embodiment: the housing base 5 is provided with a first installation groove 51, a second installation groove 52 and a third installation groove 53, the described The first installation groove 51 and the second installation groove 52 are opened on the upper surface of the housing base 5, and the first installation groove 51 and the second installation groove 52 are adjacent; the third installation groove 53 is opened on a side surface of the housing base 5 , and the thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com