Clean workshop

A technology for clean workshops and workshops, which can be used in household heating, space heating and ventilation details, heating methods, etc. It can solve the problems of occupancy, high construction costs of clean workshops, high construction and operation costs of clean areas, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with the accompanying drawings. Apparently, the described embodiments are only some of the embodiments of the present invention, rather than all of them. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

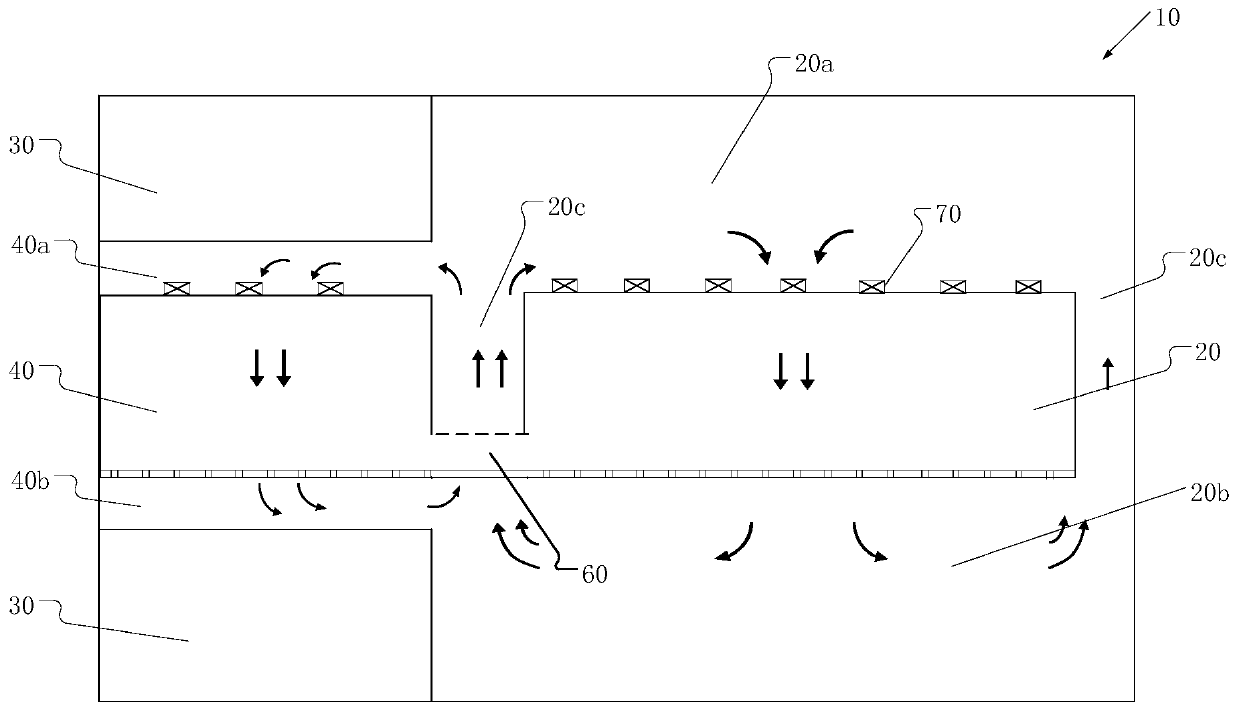

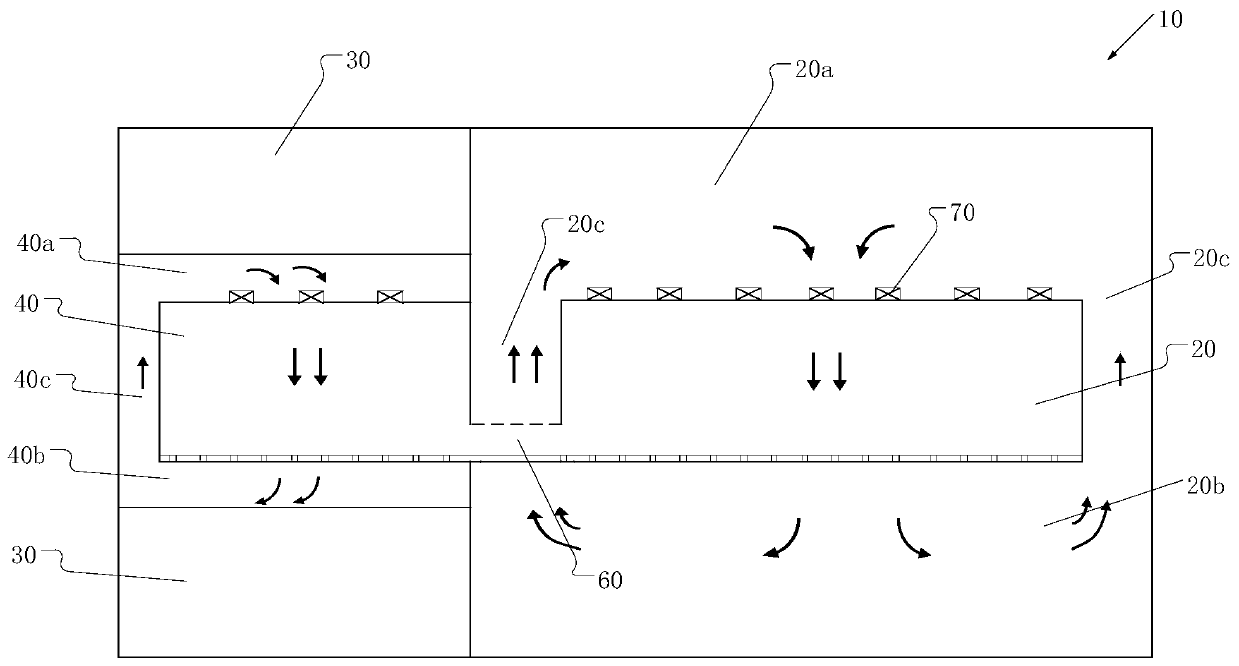

[0036] The embodiment of the present invention provides a clean factory building. The total area of the clean area is enlarged by setting a side-span clean room in the factory building, and the side-span clean room and the auxiliary room in the side-span support area are stacked in space to avoid The additional area occupied by the workshop increases the effective area utilization rate of the clean workshop.

[0037] Specifically, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com