Prestress-free tough steel structure composed of hinging columns and elastic resetting beam

An elastic reset and steel structure technology, applied in the direction of building components, building structures, building types, etc., can solve the problems of reducing energy consumption of nodes, repairing difficult floor slabs after earthquakes, complex construction, etc., to solve the problem of prestress loss, avoid The effect of prestressing process and improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

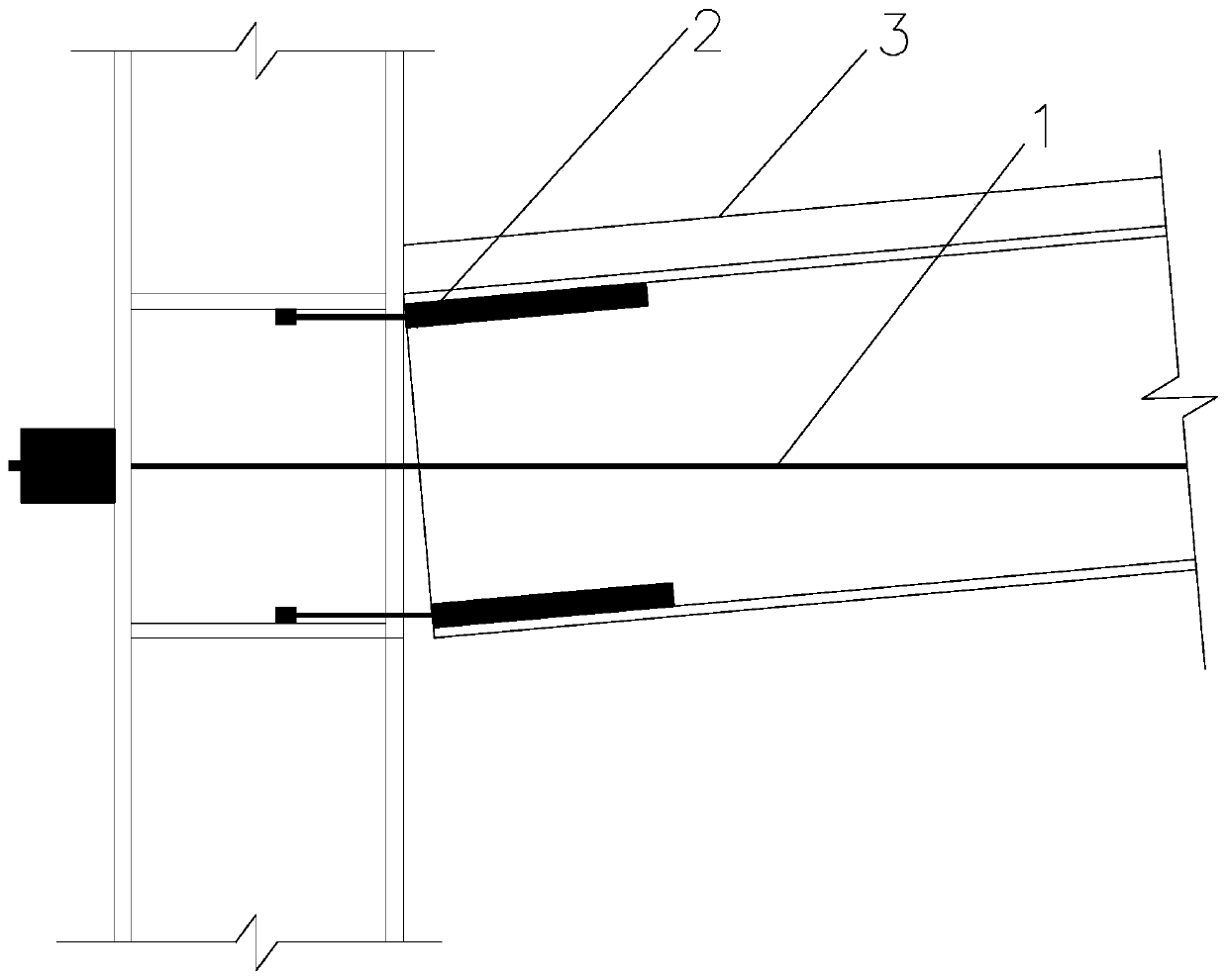

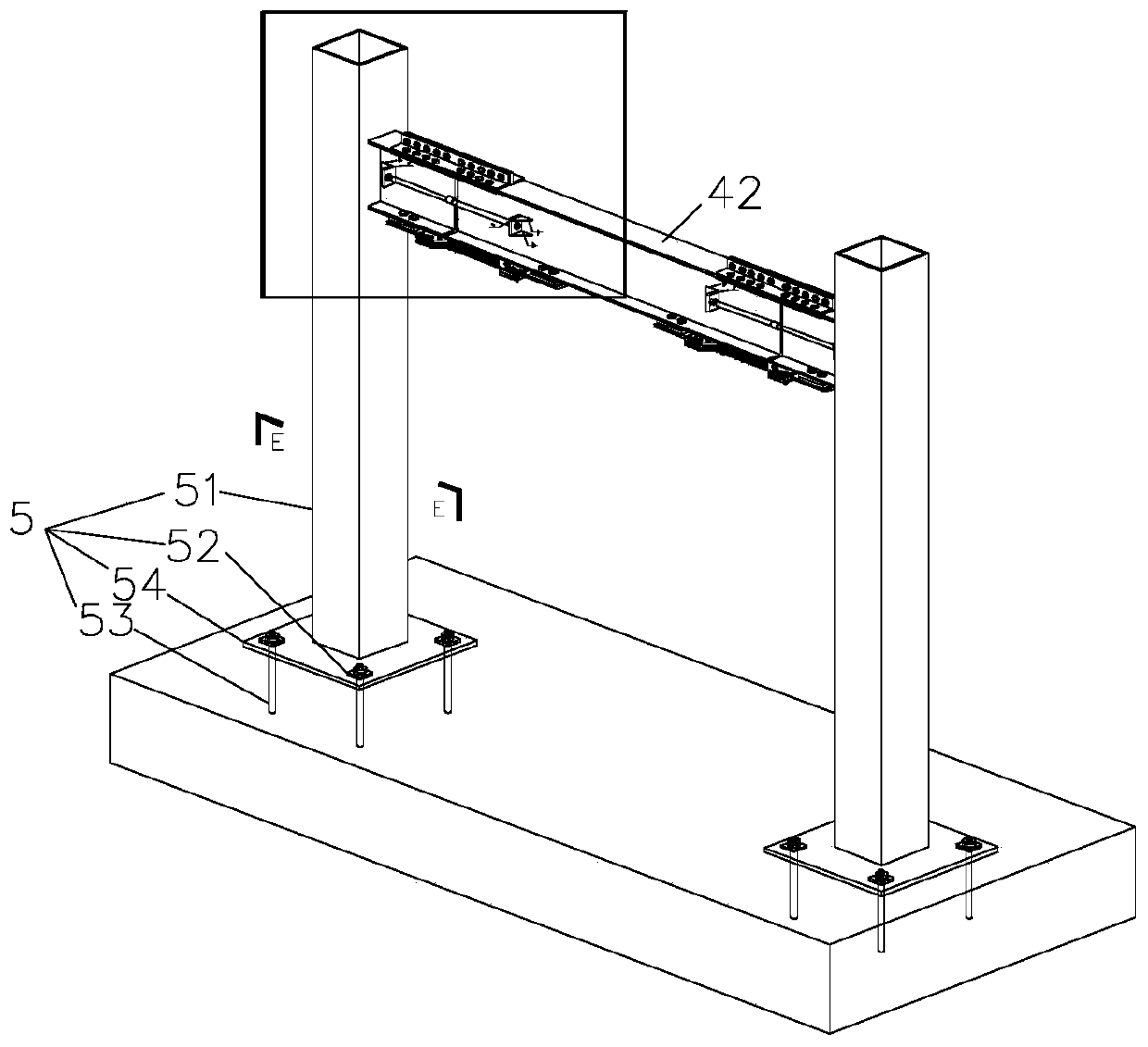

[0045] Combined with Figure 3- Figure 9 , Figure 13 To illustrate, a prestress-free ductile steel structure composed of a hinged column and an elastic reset beam includes an elastic reset beam 4 and two hinged box-shaped columns 5 at the foot of the column; an elastic reset beam 4 includes two cantilever sections I-shaped Steel beam 41, an I-shaped steel beam 42 in the middle section, two suspension connectors 43, four upper friction pads 44, two buckling-constrained energy dissipation plates 45 and four buckling-constrained high-strength steel bars 46; two cantilever sections The I-shaped steel beams 41 in the middle section are connected to the I-shaped steel beams 42, and the four buckling-constrained high-strength steel rods 46 are respectively fixed and arranged symmetrically on both sides of the beam web along the central axis of the beams, so as to connect the I-shaped steel beams 41 and the cantilever section. The effect of the I-shaped steel beam 42 in the middle s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com