Water passing box culvert on soft soil foundation and construction method of water passing box culvert

A soft soil foundation and box culvert technology, applied in soil protection, infrastructure engineering, road bottom and other directions, can solve the problems of pile foundation quality problems, troublesome handling, long construction and inspection time, and high construction costs, saving inspection time. , The effect of short construction time and low construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

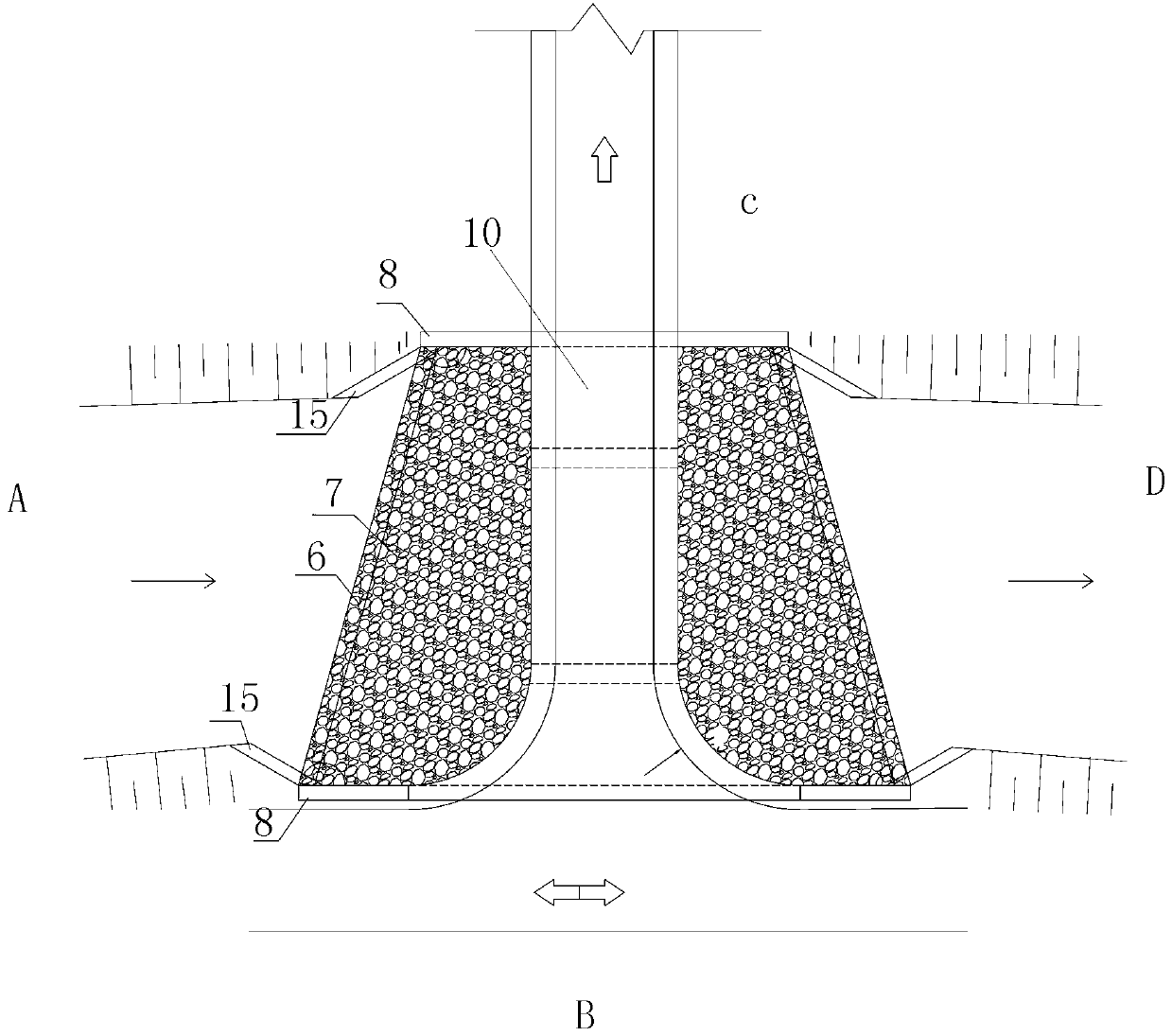

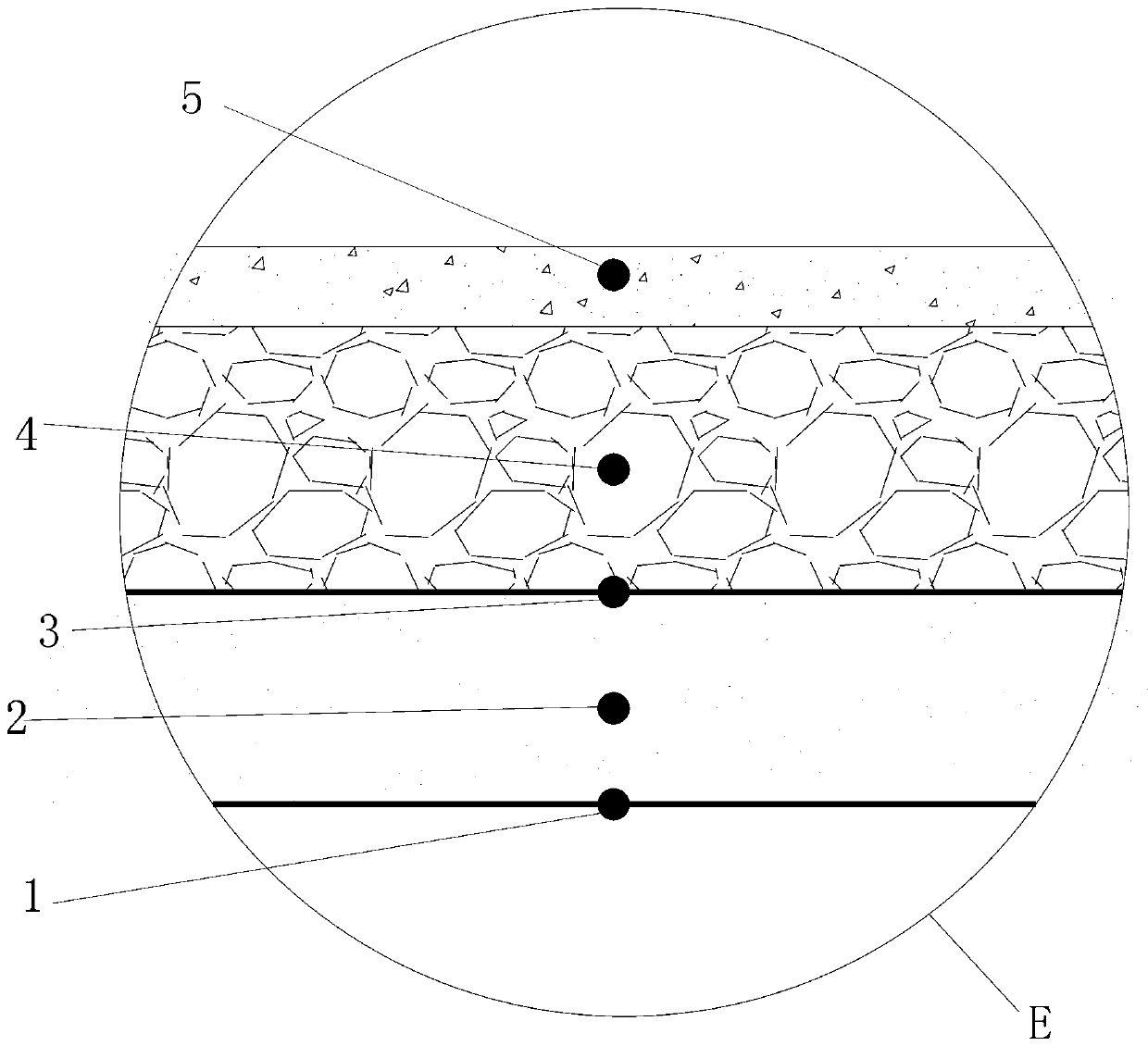

[0032] The preferred solution is as Figure 1 to Figure 6 As shown, a water-passing box culvert on a soft soil foundation includes a box culvert foundation, and the box culvert foundation includes a reinforced filter layer 1, a gravel soil layer 2, a durable reinforced filter layer 3, and a graded filter layer from bottom to top. Gravel layer 4 and cushion layer 5, wherein the thickness of gravel soil layer 2 is 50-60cm, preferably 50cm, and the compaction degree of gravel soil layer 2 is more than or equal to 94%; the thickness of graded gravel layer 4 is 50-60cm, preferably 50cm, graded The compaction degree of the crushed stone layer 4 is ≥96%; the cushion layer 5 is made of C20 plain concrete, and the thickness of the cushion layer 5 is between 15-20cm, preferably 15cm;

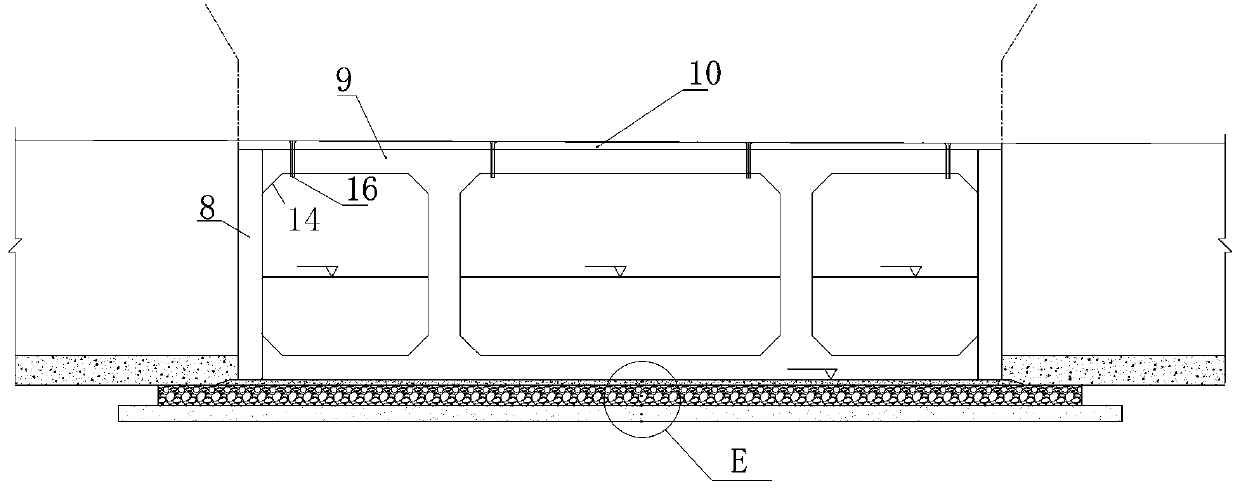

[0033] A water box culvert 9 is poured on the cushion layer 5; the body of the water box culvert 9 is a frame structure with a single box and three rooms, and the frame of the single box and three rooms f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com