Composite absorbent and method of utilizing the same for coupled ethylene oxide absorption and conversion for ethylene carbonate co-production

A technology of ethylene carbonate and ethylene oxide, used in chemical instruments and methods, organic compound/hydride/coordination complex catalysts, organic chemistry, etc., can solve the complex process, large one-time investment and large consumption. energy and other issues to achieve the effect of ensuring safety, reducing energy consumption and costs, and reducing exhaust gas content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

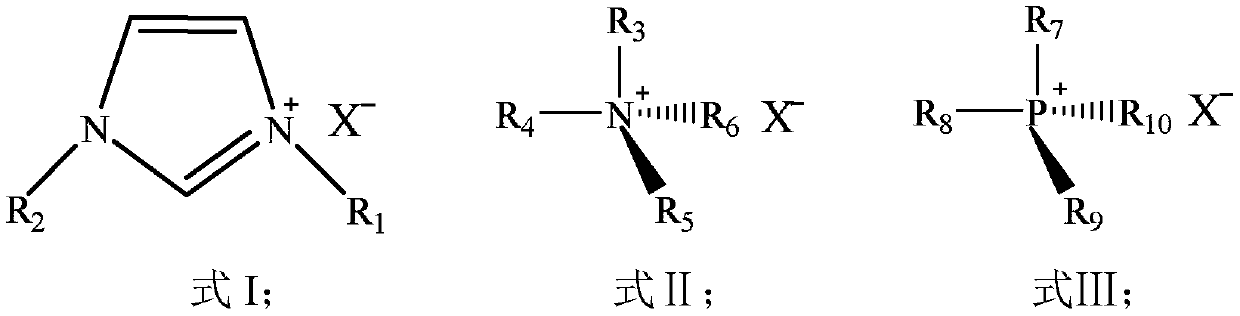

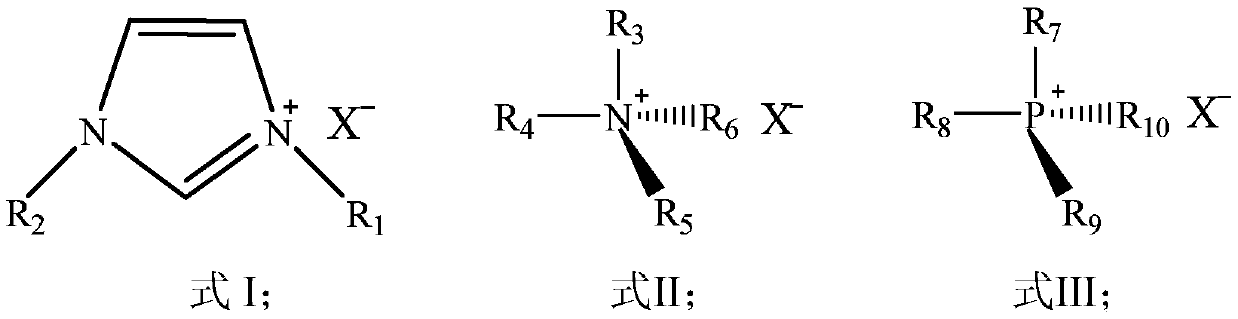

[0042] This embodiment provides a composite absorbent and its method for the coupled co-production of ethylene carbonate in the absorption and transformation of ethylene oxide. The specific operation steps are as follows:

[0043] The feed gas containing 2.26mol% ethylene oxide at 80°C enters the absorption tower from the bottom of the tower, and the composite absorbent ionic liquid 1-(2-hydroxyethyl)-3-methylimidazolium bromide ([Hemim]Br) and carbonic acid Vinyl esters are mixed uniformly at a mass ratio of 1:10 and then enter from the top of the absorption tower (T1). The raw material gas is in countercurrent contact with the absorbent. The absorption temperature is 80°C, the operating pressure is 2MPa, the liquid-to-gas mass ratio is 3, The conversion rate of ethylene oxide in the conversion section is 28.8%, the concentration of ethylene oxide at the top of the absorption tower is 69ppm, and the absorption rate at this time is 99.9%.

[0044] Add the above absorbing liqui...

Embodiment 2

[0046] This embodiment provides a composite absorbent and its method for the coupled co-production of ethylene carbonate in the absorption and transformation of ethylene oxide. The specific operation steps are as follows:

[0047] The feed gas containing 2.26mol% ethylene oxide at 80°C enters the absorption tower from the bottom of the tower, and the composite absorbent ionic liquid 1-hexyl-3-methylimidazolium bromide ([Hmim]Br) and ethylene carbonate are mixed in a ratio of 1:10 After the mass ratio is mixed evenly, it enters from the top of the absorption tower (T1), and the raw material gas is in countercurrent contact with the absorbent. The absorption temperature is 80°C, the operating pressure is 2MPa, the liquid-gas mass ratio is 3, and the ethylene oxide in the pre-reforming section is absorbed. The conversion rate of the product is 15.8%, the concentration of ethylene oxide at the top of the absorption tower is 227ppm, and the absorption rate is 99.5% at this moment. ...

Embodiment 3

[0050] This embodiment provides a composite absorbent and its method for the coupled co-production of ethylene carbonate in the absorption and transformation of ethylene oxide. The specific operation steps are as follows:

[0051] The feed gas containing 2.26mol% ethylene oxide at 80°C enters the absorption tower from the bottom of the tower, and the composite absorbent ionic liquid 1-(2-hydroxyethyl)-3-methylimidazolium bromide ([Hemim]Br) and carbonic acid Vinyl esters are mixed evenly at a mass ratio of 1:9 and enter from the top of the absorption tower (T1). The raw material gas is in countercurrent contact with the absorbent. The conversion rate of ethylene oxide in the conversion section is 32.2%, the concentration of ethylene oxide at the top of the absorption tower is 44ppm, and the absorption rate at this time is 99.9%.

[0052] Add the above absorbing solution into the reactor, raise the reaction temperature to 120°C, and react for 1 hour under the pressure of 2MPa. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com