Wheel moving device for vehicle maintenance

A mobile device and vehicle maintenance technology, which is applied to vehicle control devices, vehicle maintenance, shunting equipment, etc., can solve the problems of potential safety hazards of injury, large tire dimensions and quality, and high labor intensity of workers to achieve convenient maintenance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

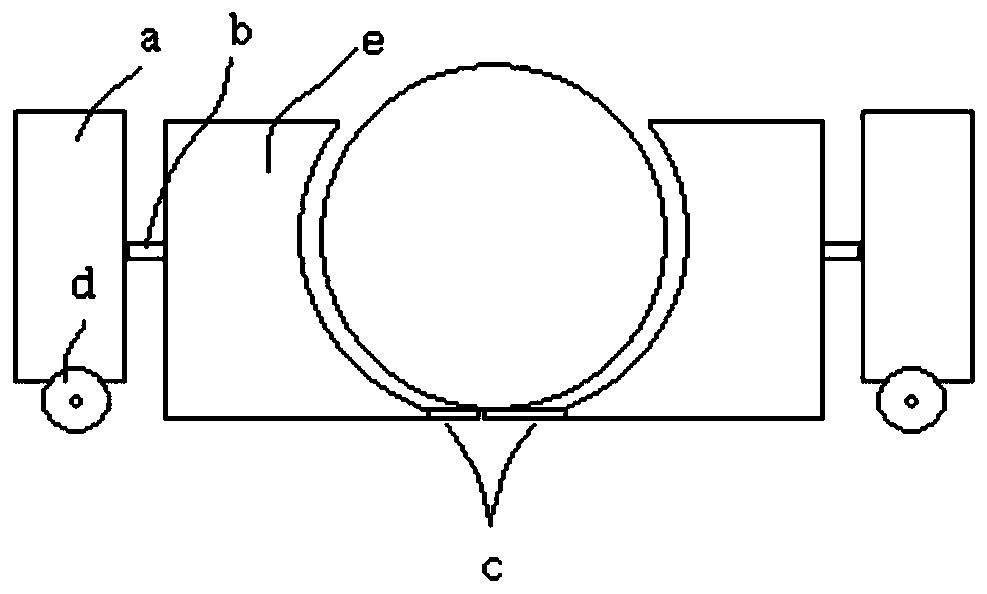

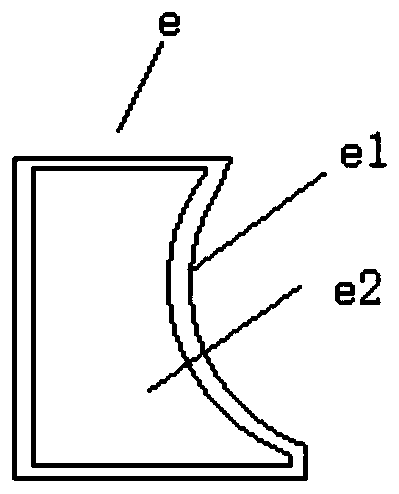

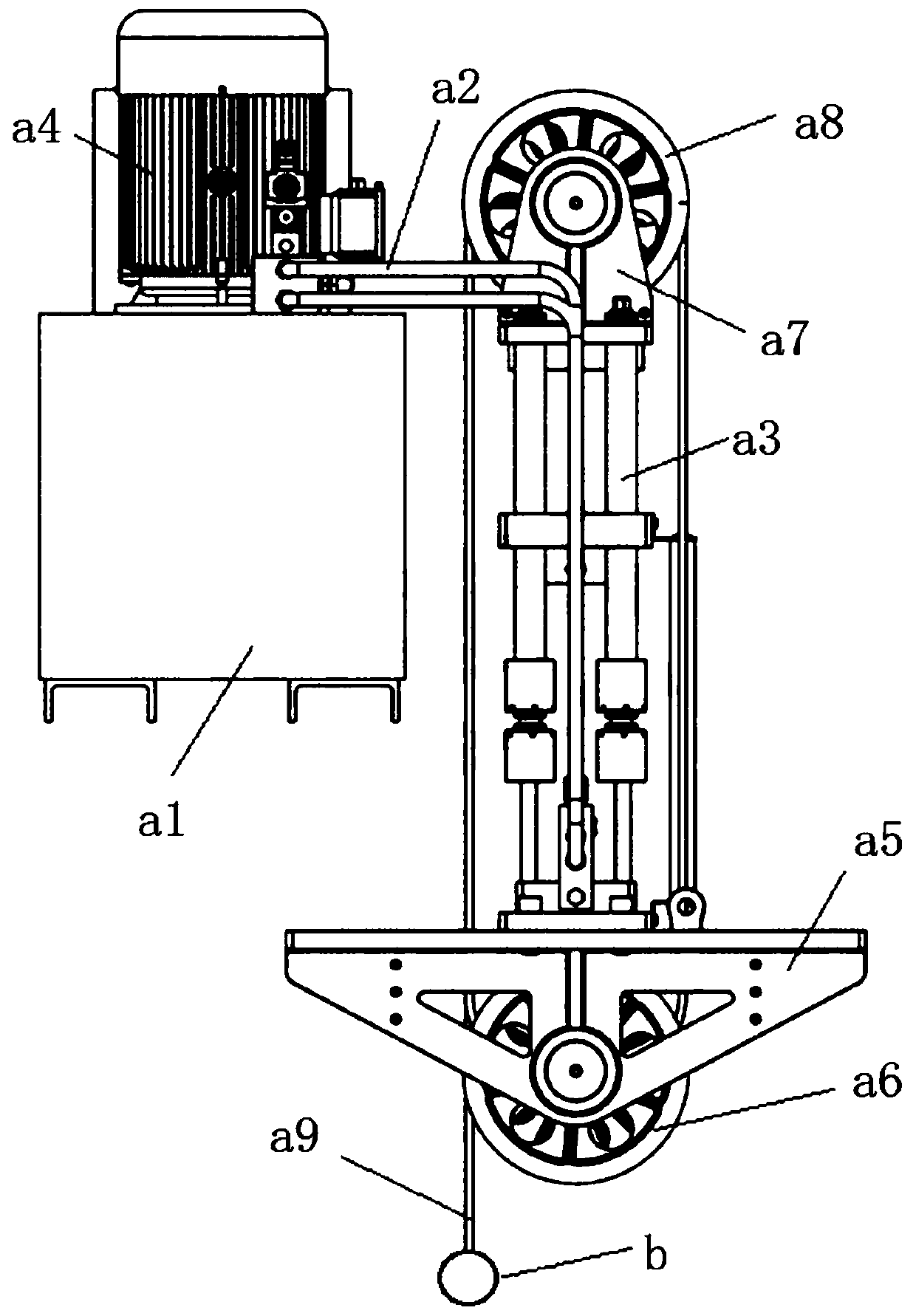

[0019] During specific implementation, a wheel moving device for vehicle maintenance, such as figure 1 , an embodiment of the wheel moving device for vehicle maintenance, including a pair of lifting components a and a pair of fixing components e for fixing the wheels, the bottom of the lifting component a is provided with a self-driving wheel d, and the lifting component a The fixed assembly e on one side is connected through the fixed shaft b and the lifting adjustment of the fixed assembly e is realized. The fixed assembly e is provided with an arc-shaped groove opposite to the outer contour of the wheel. The concave grooves of the above-mentioned pair of fixed assemblies e The bottom between the grooves is provided with a self-fastening component c; during implementation, the driving displacement of each lifting component a and fixed component e is realized through the self-driving wheel d. When the vehicle cannot move and needs maintenance, a pair of lifting components are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com