A 3D printer with purification function and purification control system

A 3D printer and control system technology, applied in the field of 3D printing, can solve the problems of inability to purify toxic ultrafine particles, death, affecting people's life safety, etc., to achieve good purification control effect, ensure safe use, and good purification effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

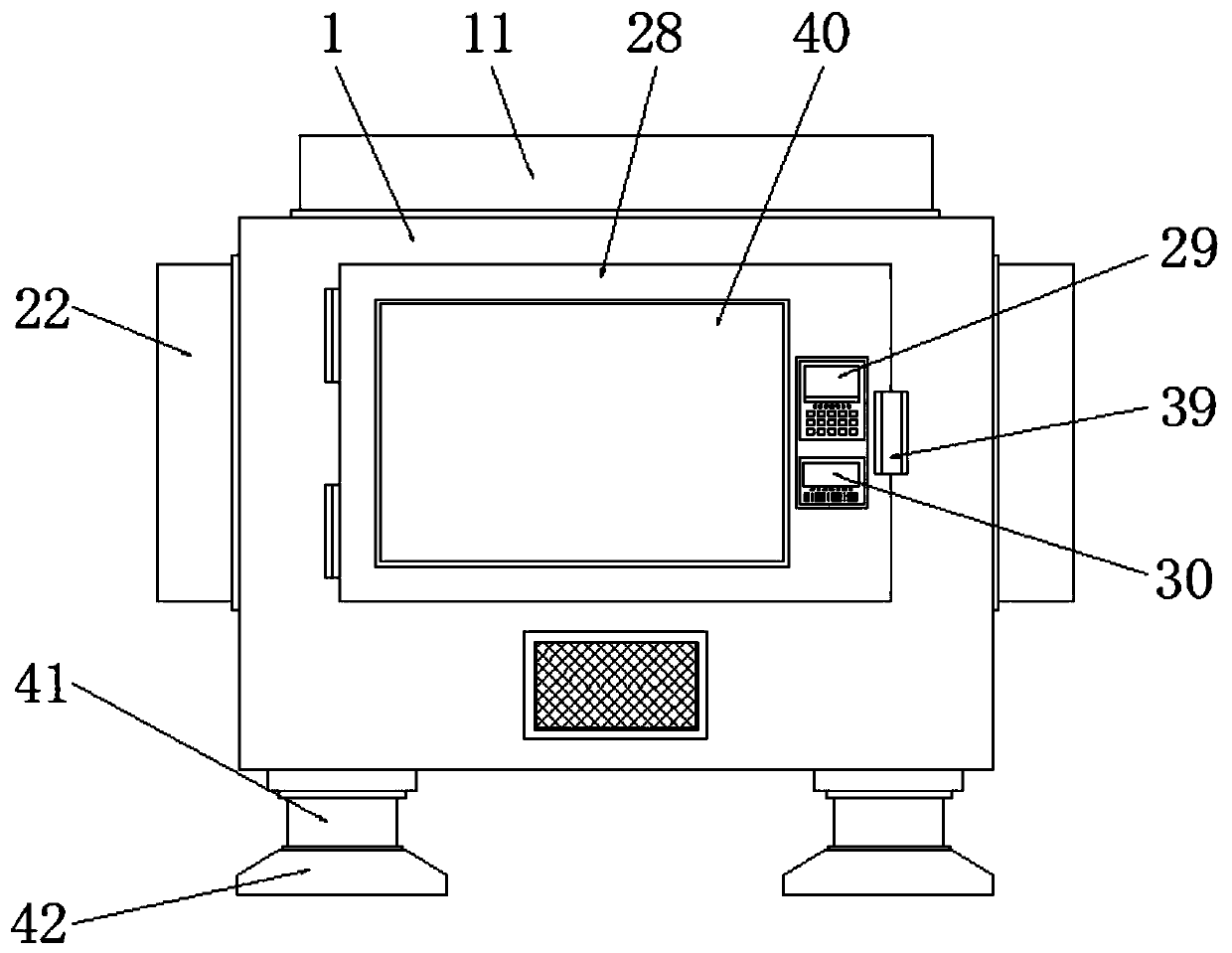

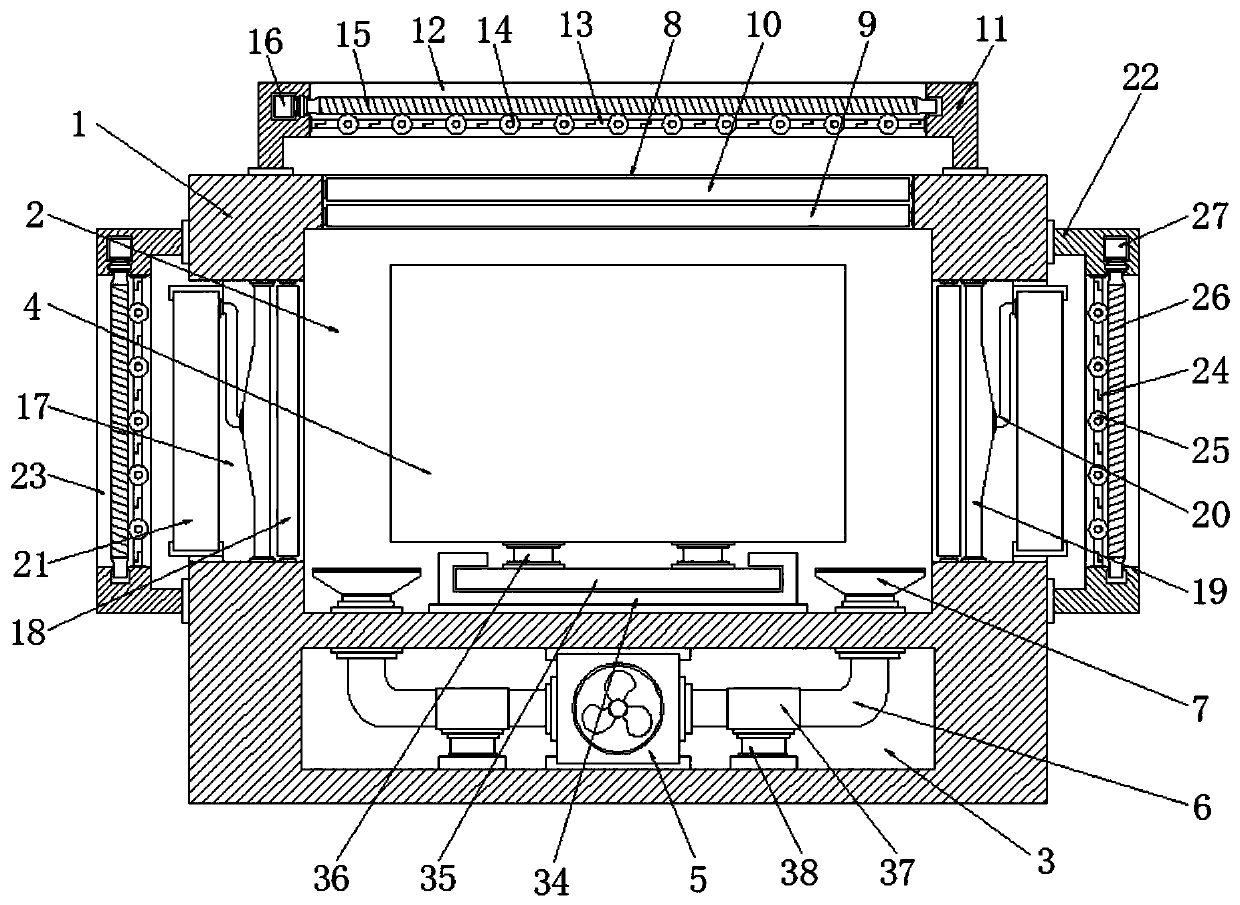

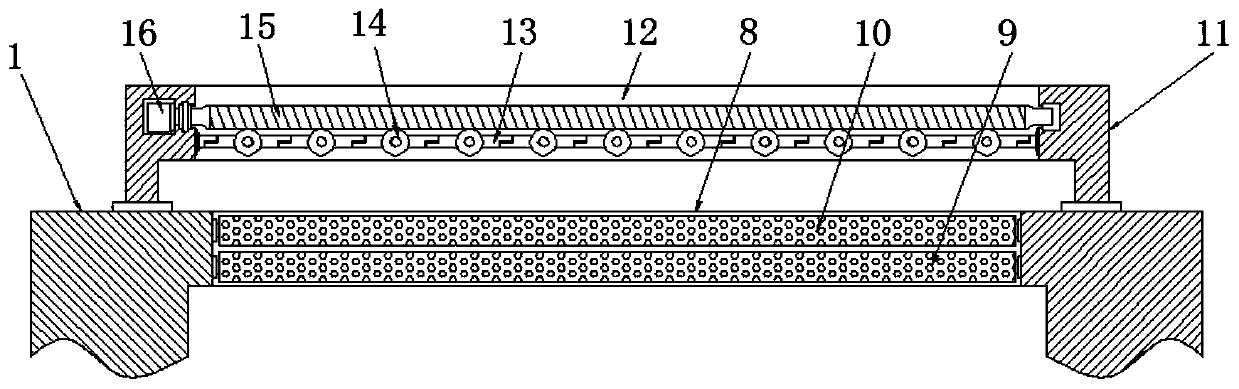

[0034] Embodiment one, such as Figure 1-7As shown, a 3D printer with a purification function according to an embodiment of the present invention includes a box body 1, and the interior of the box body 1 is provided with a placement cavity 2 and an installation cavity 3, and the interior of the placement cavity 2 is installed with 3D printer body 4, a fan-5 is installed inside the installation cavity 3, the fan-5 is a blower, and air duct-6 is installed on both sides of the fan-5, and the air duct One end of one 6 away from the fan one 5 runs through and extends to both sides of the bottom end of the placement cavity 2, the end of the air duct one 6 away from the fan one 5 is equipped with a windshield 7, and the box The top of the body 1 is provided with an opening one 8, and a filter plate one 9 and a filter plate two 10 are installed inside the opening one 8, through the fan one 5 and the wind cover 7 and the filter plate one 9 and The interaction between the two filter pl...

Embodiment 2

[0035] Embodiment two, such as figure 2 , 5 , 7, the end of the air duct 20 away from the fan 19 is connected to the top of the side of the purification chamber 21 close to the fan 19, and the interior of the purification chamber 21 is equipped with a connection pipe 31, and the top of the connecting pipe 31 communicates with the air pipe two 20; the top of the side of the purification chamber 21 away from the air pipe two 20 has an opening three 32, and the purification chamber 21 A baffle 33 is installed on the bottom of the opening three 32 and close to the side of the connecting pipe 31; when in use, the fan two 19 absorbs the toxic ultrafine particles in the box 1, and passes through The interaction between the air duct two 20 and the connecting pipe 31 is transported to the purification chamber 21, and the toxic ultrafine particles contained in the air are purified and filtered through the purification liquid in the purification chamber 21, and then passed through The...

Embodiment 3

[0036] Embodiment three, such as figure 2 As shown, a slot plate 34 is installed at the inner bottom end of the placement cavity 2, and a support plate 35 adapted to the groove of the slot plate 34 is installed inside the slot plate 34, and the support plate 35 The top of the top is symmetrically equipped with support blocks 36, and the tops of the support blocks 36 are all fixedly connected with the bottom end of the 3D printer body 4; the groove plate 34 is compatible with the support plate 35, and the support The plate 35 is clamped in the plate groove at the top of the groove plate 34. When in use, the 3D printer body 4 can slide on the top of the groove plate through the action of the support block 36, thereby facilitating People maintain and check the 3D printer body 4 , and at the same time, it is convenient to take out the 3D printed product after printing, which is convenient for people to use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com