Large modulus spur gear precision forging cold finishing forming method and die

A spur gear and precision forging technology, which is applied in the manufacture of tools, wheels, forging/pressing/hammer devices, etc., can solve the problems of low mold life, low tooth profile accuracy, and poor tooth surface quality, and improve the quality of gears. Effects of performance and service life, improvement of forging accuracy, improvement of tooth profile accuracy and surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0014] Embodiment 1: In this embodiment, a method for precision forging and cold-finishing of large-modulus spur gears for helicopters is specifically carried out according to the following steps:

[0015] 1. Gear blank preparation: According to the design requirements of gear parts, blanking is carried out, and the center split hole is prefabricated in the center of the blank according to the size of the part to obtain the gear blank;

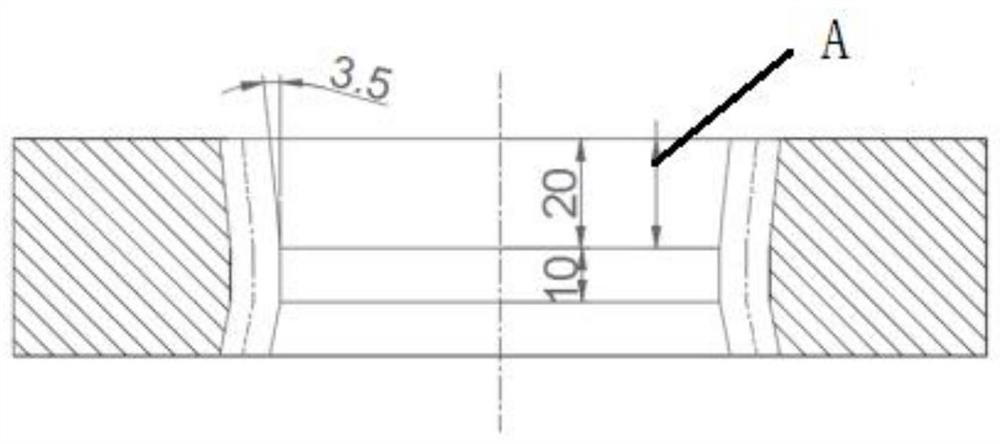

[0016] 2. Cold finishing: use cold finishing to reduce and extrude the tooth blank to obtain the tooth blank after cold finishing;

[0017] 3. End face trimming: remove the burrs on the end face of the tooth blank after cold finishing.

[0018] This embodiment improves the tooth shape precision and tooth surface quality of the forged gear, reduces the forming load, and realizes near-net shaping of the spur gear with large modulus. The forged gear is trimmed by cold finishing, which reduces the subsequent cutting process of the gear surface an...

specific Embodiment approach 2

[0021] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the diameter of the central distribution hole in Step 1 is 45mm. Others are the same as the first embodiment.

specific Embodiment approach 3

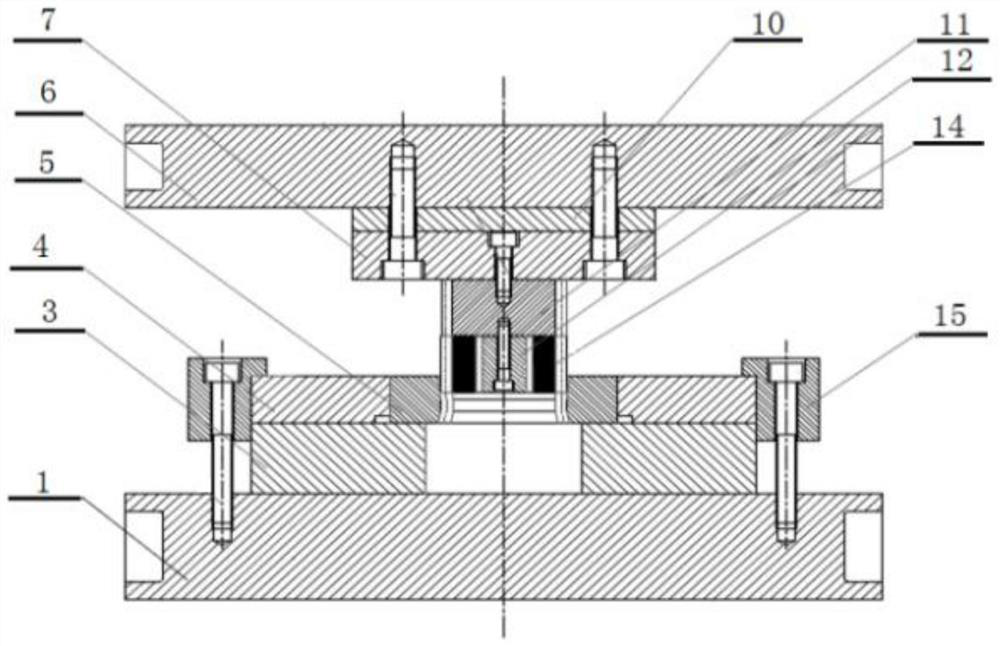

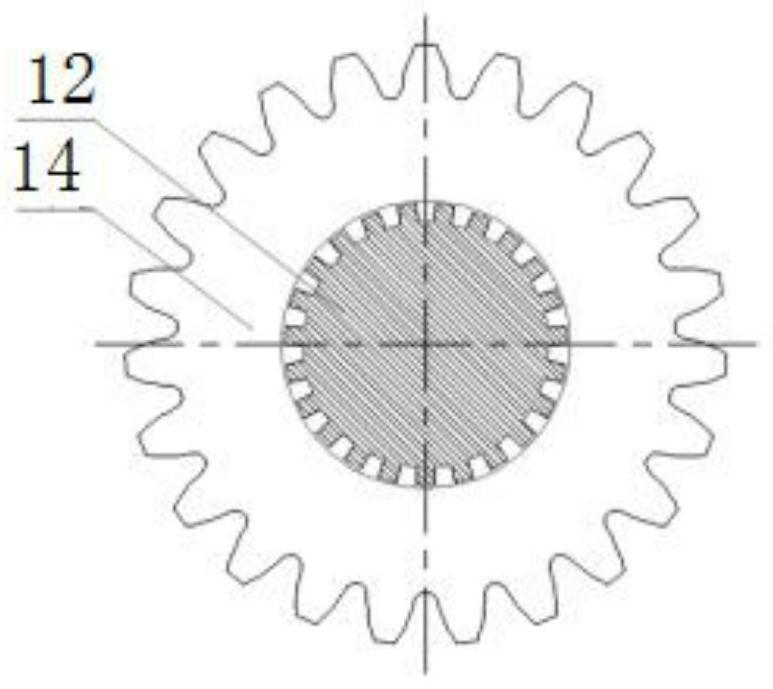

[0022] Specific embodiment three: the mold of the precision forging cold finishing forming method of large modulus spur gears for helicopters in this embodiment includes a pre-tightening die device and a punch device; the pre-tightening die device consists of die 5, pre-tightening die device Ring 4, lower backing plate 3 and die fixing ring 15, the interference fit between die 5 and pre-tightening ring 4, the die 5, pre-tightening ring 4, lower backing plate are connected by die fixing ring 15 and bolts 3 is connected with the lower template 1; the punch device is composed of a punch 11, a toothed mandrel 12, a punch fixing plate 7, an upper backing plate 10 and an upper template 6, and the punch 11 is a toothed punch, and the teeth are connected by bolts Shaped mandrel 12, punch 11, upper backing plate 10, punch fixing plate 7 are connected with upper template 6 to ensure that toothed mandrel 12 tooth tops correspond to punch 11 tooth roots, and toothed mandrel 12 tooth roots ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com