A kind of soldering method of electronic component pins

A technology of electronic components and brazing methods, which is applied in the direction of electrical components, electrical components, and electrical components to assemble printed circuits, etc., can solve the problems of varistor shaking hands, pin bending and contact, causing danger, etc., to achieve Ease of soldering, pin breakage prevention, and pin bending prevention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

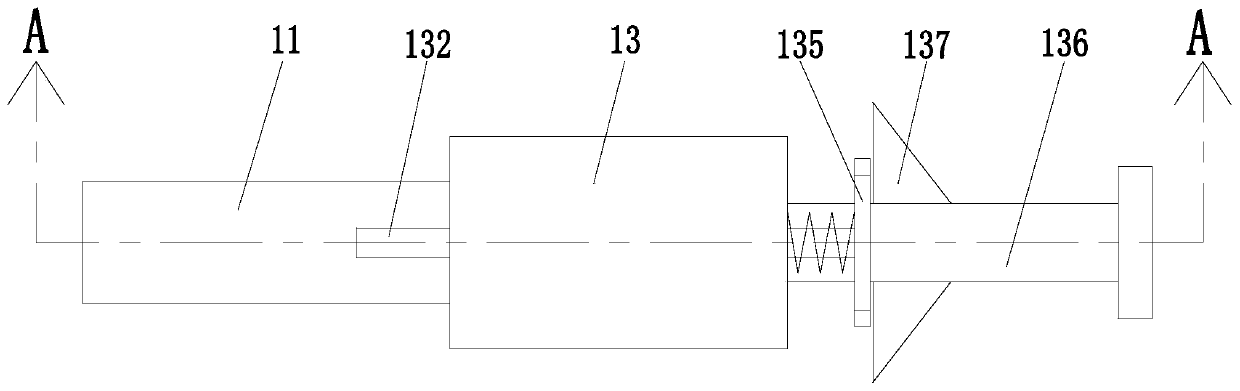

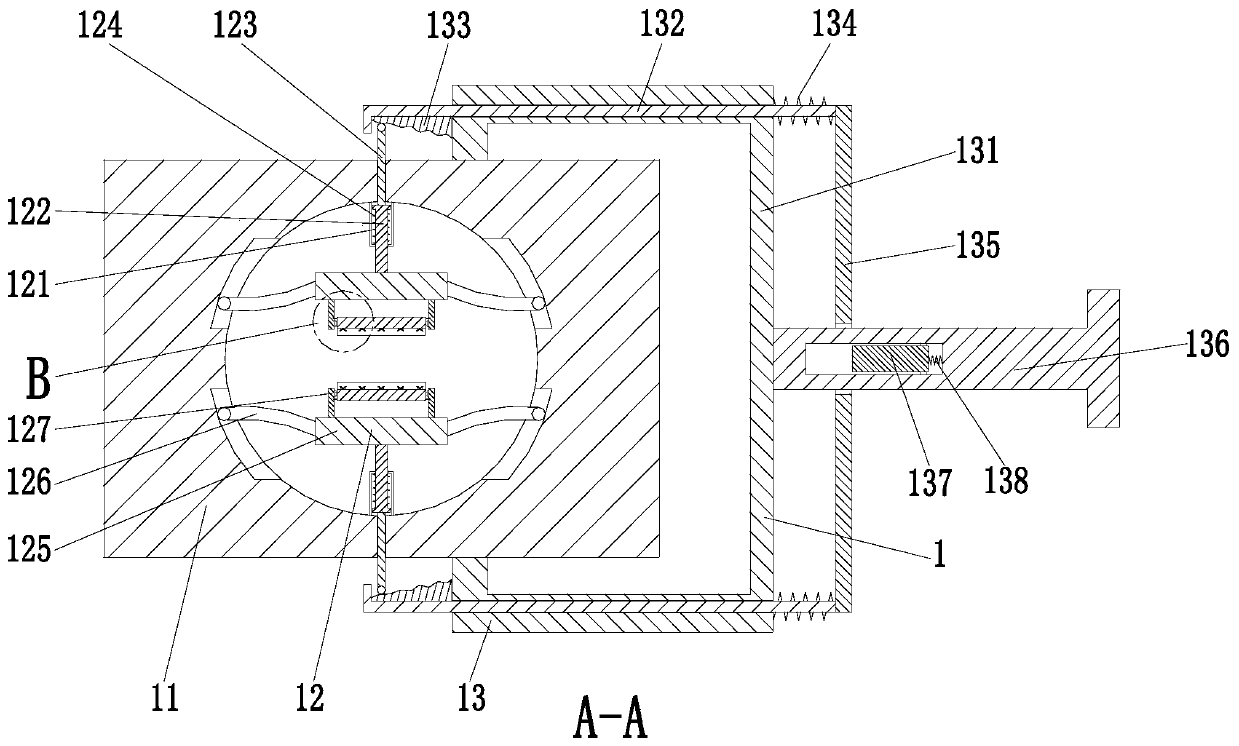

[0026] In order to make the technical means, creative features, objectives and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other.

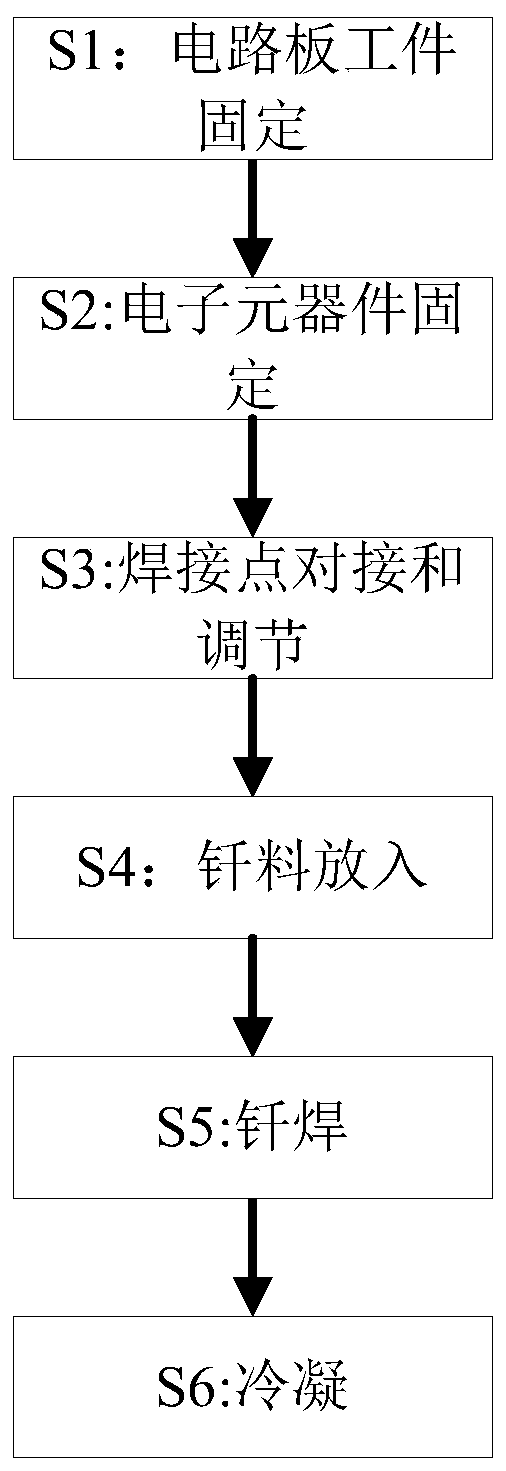

[0027] Such as Figure 1 to Figure 4 As shown, a method for brazing the pins of electronic components, the specific steps of brazing the pins of the piezoresistor are as follows:

[0028] S1. Circuit board workpiece fixation: clean the pressure-bearing platform, fix the cleaned circuit board on the pressure-bearing platform, and place the end of the circuit board to be soldered outside when fixing;

[0029] S2. Fixing the electronic components: fixing the varistor to be brazed by the fixing fixture 1;

[0030] S3. Welding point docking and adjustment: Assemble the piezoresisto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com