A kind of silicon carbon negative electrode material for lithium ion battery and preparation method thereof

A lithium-ion battery, negative electrode material technology, applied in battery electrodes, nanotechnology for materials and surface science, negative electrodes, etc., can solve problems such as poor cycle performance, achieve high specific capacity, suppress volume changes, charge The effect of high discharge efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 1. Preparation of silicon carbon anode material:

[0029] Prepare 500 mL of 0.1% carboxymethyl cellulose aqueous solution, add 3 g of sucrose, and stir evenly; then add 3 g of silicon powder to prepare a suspension, mechanically stir at 100 r / min for 1 hour, then ultrasonically disperse for 0.5 hour, and then disperse at 200 r / min Stir mechanically at a rotating speed for 12 hours to prepare a suspension.

[0030] The above suspension was transferred to a sand mill, and sand milled for 0.5 hour, and the speed of the sand mill was 1200r / min.

[0031] Add 2 mL of polyethylene glycol as a dispersant to the sanded suspension, and stir until uniform; then spray dry while stirring to obtain a black powder. The temperature is 80°C, the feed rate is 10mL / min, and the pressure is 0.05Mpa.

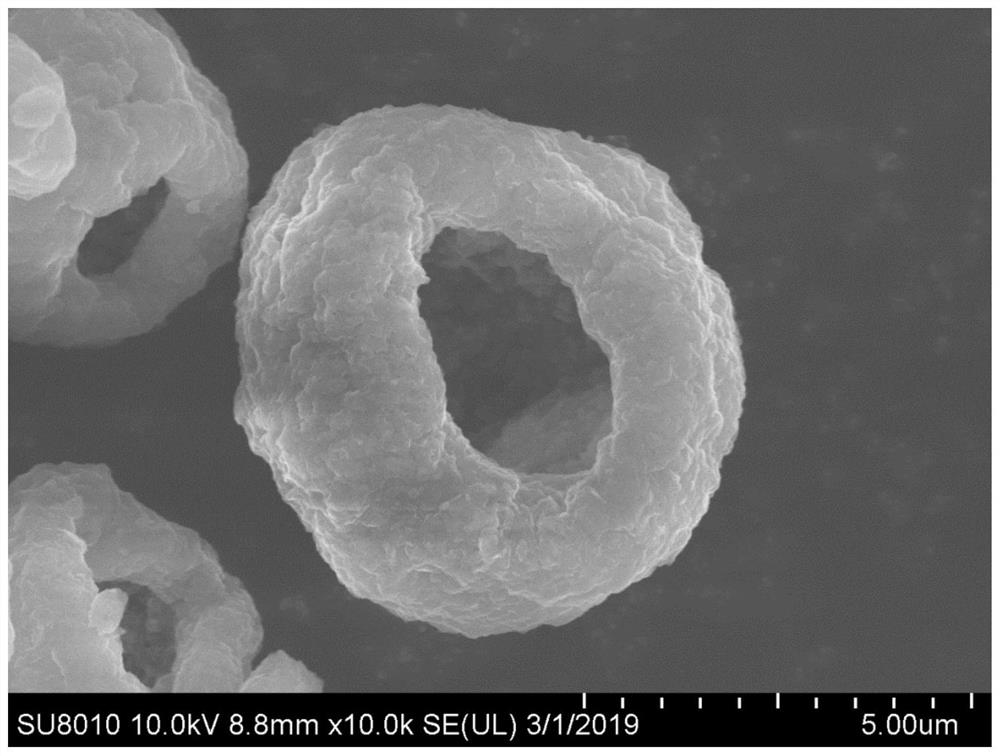

[0032] The black powder was calcined at 500° C. for 2 hours under an argon atmosphere to obtain a silicon-carbon negative electrode material with a ring structure.

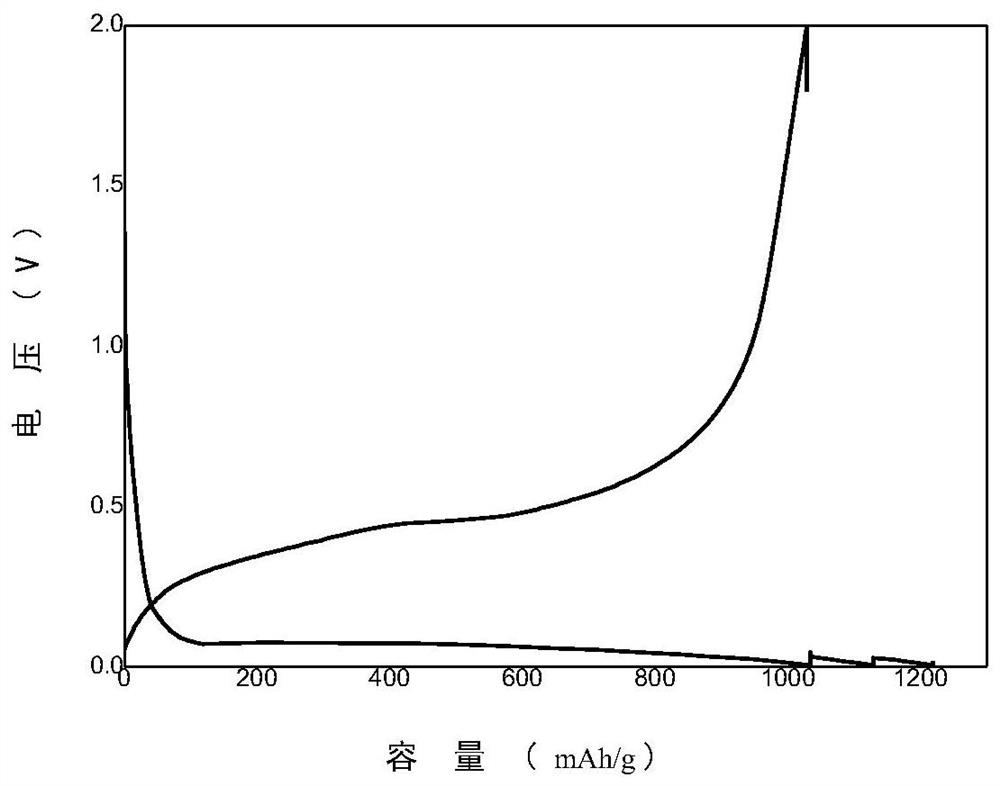

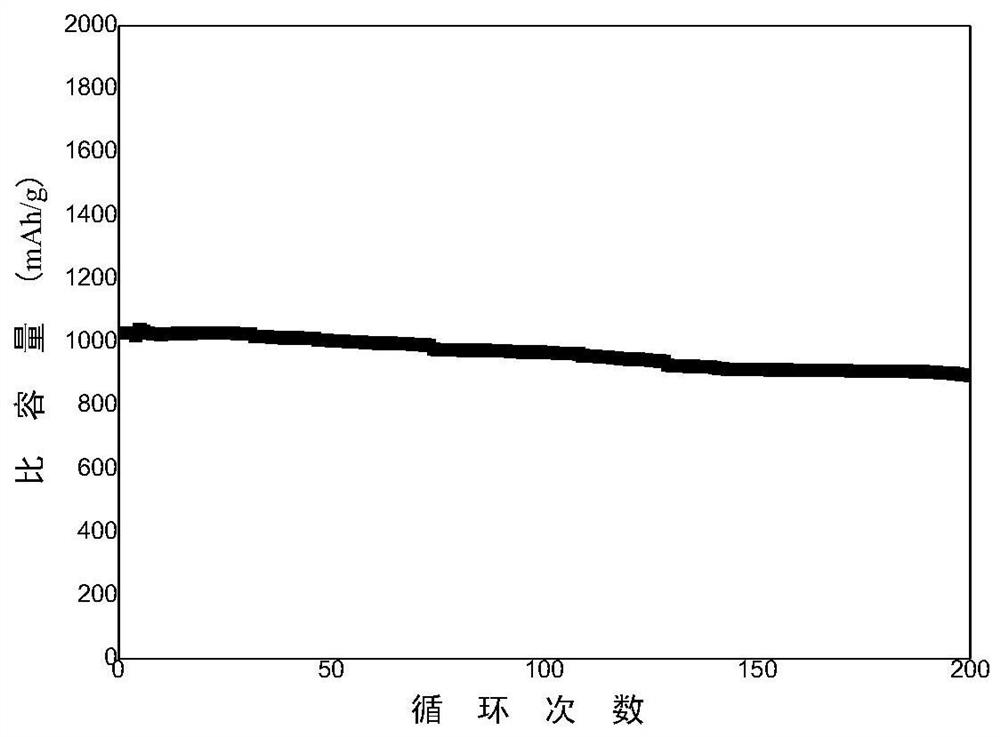

[0033] 2. Test the sil...

Embodiment 2

[0040] 1. Preparation of silicon carbon anode material:

[0041] Prepare 500 mL of 2% carboxymethyl cellulose aqueous solution, add 10 g of sucrose, and stir evenly; then add 20 g of silicon powder to prepare a suspension, mechanically stir at 100 r / min for 1 hour, then ultrasonically disperse for 0.5 hour, and then disperse at 200 r / min Stir mechanically at a rotating speed for 12 hours to prepare a suspension.

[0042] The above-mentioned suspension was transferred to a sand mill, and sand milled for 5 hours, and the speed of the sand mill was 2000r / min.

[0043] Add 20 mL of dispersant methyl amyl alcohol to the sand-milled suspension, and mechanically stir until uniform; then spray-dry while stirring. The speed is 2mL / min, the pressure is 0.4Mpa, and a black powder is obtained.

[0044] Dissolve 0.5g of sucrose in water to prepare a secondary carbon source solution, disperse the black powder prepared above in the secondary carbon source solution, dry in vacuum at 60°C, a...

Embodiment 3

[0050] 1. Preparation of silicon carbon anode material:

[0051] Prepare 500 mL of 0.01% carboxymethyl cellulose aqueous solution, add 8 g of sucrose, and stir evenly; then add 5 g of silicon powder to prepare a suspension, mechanically stir at 100 r / min for 1 hour, then ultrasonically disperse for 0.5 hour, and then disperse at 200 r / min Stir mechanically at a rotating speed for 12 hours to prepare a suspension.

[0052] The above-mentioned suspension was transferred to a sand mill, and sand milled for 1 hour, and the speed of the sand mill was 1500r / min.

[0053] Add 3 mL of dispersant polyacrylic acid to the sand-milled suspension, and stir until uniform; then spray-dry while stirring. The air inlet temperature during spraying is 120°C, the outlet air temperature is 80°C, and the feed rate is 8mL / min, the pressure is 0.2Mpa, and black powder is obtained.

[0054] Dissolve 5g of glucose in water to prepare a secondary carbon source solution, disperse the black powder prepa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com