Straw boiler capable of removing coke in the furnace body

A straw boiler and furnace body technology, which is applied in the field of straw furnaces, can solve the problems of inability to meet the heating requirements of residents, insufficient combustion, and excessive moisture in the straw.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

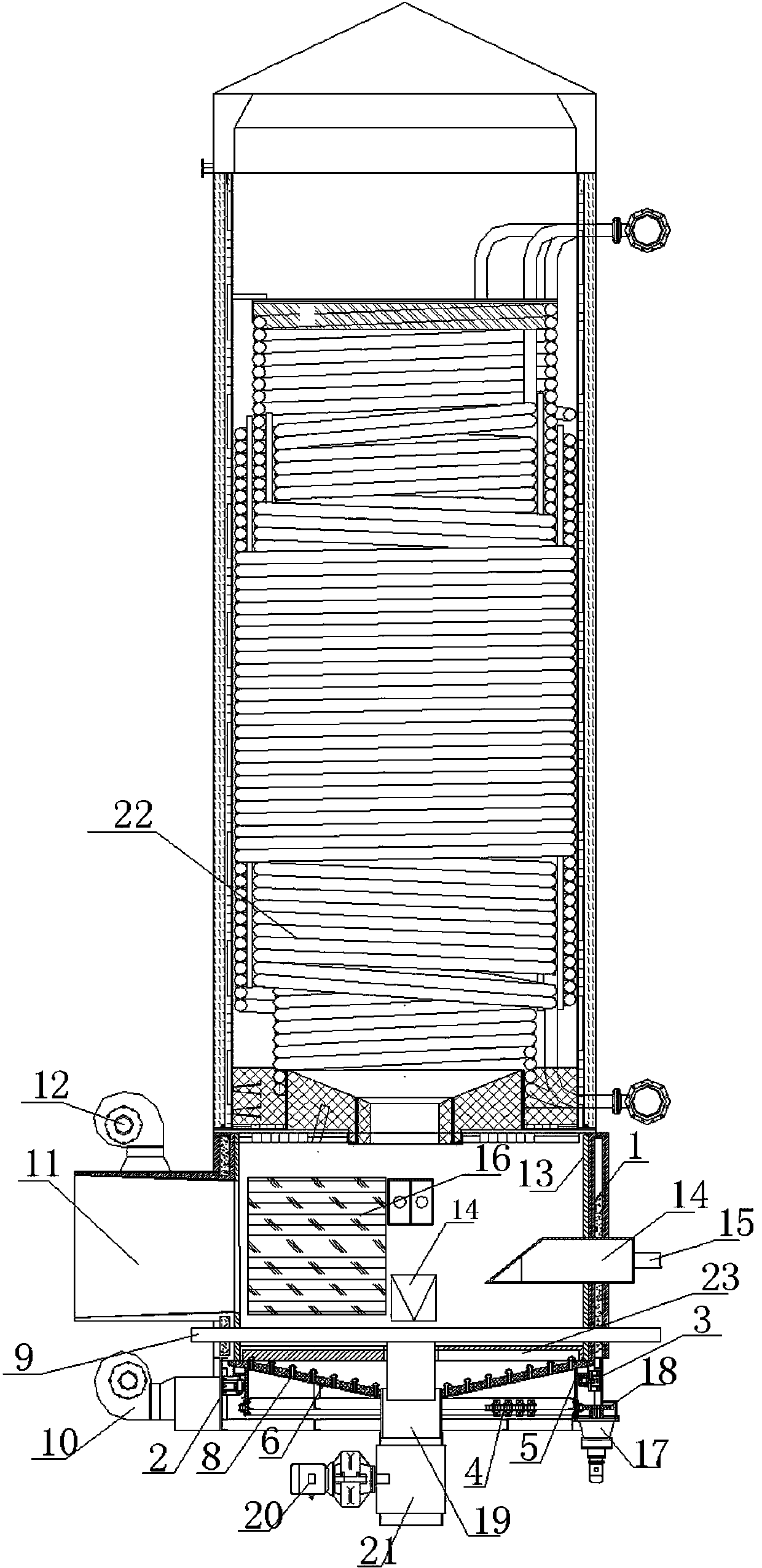

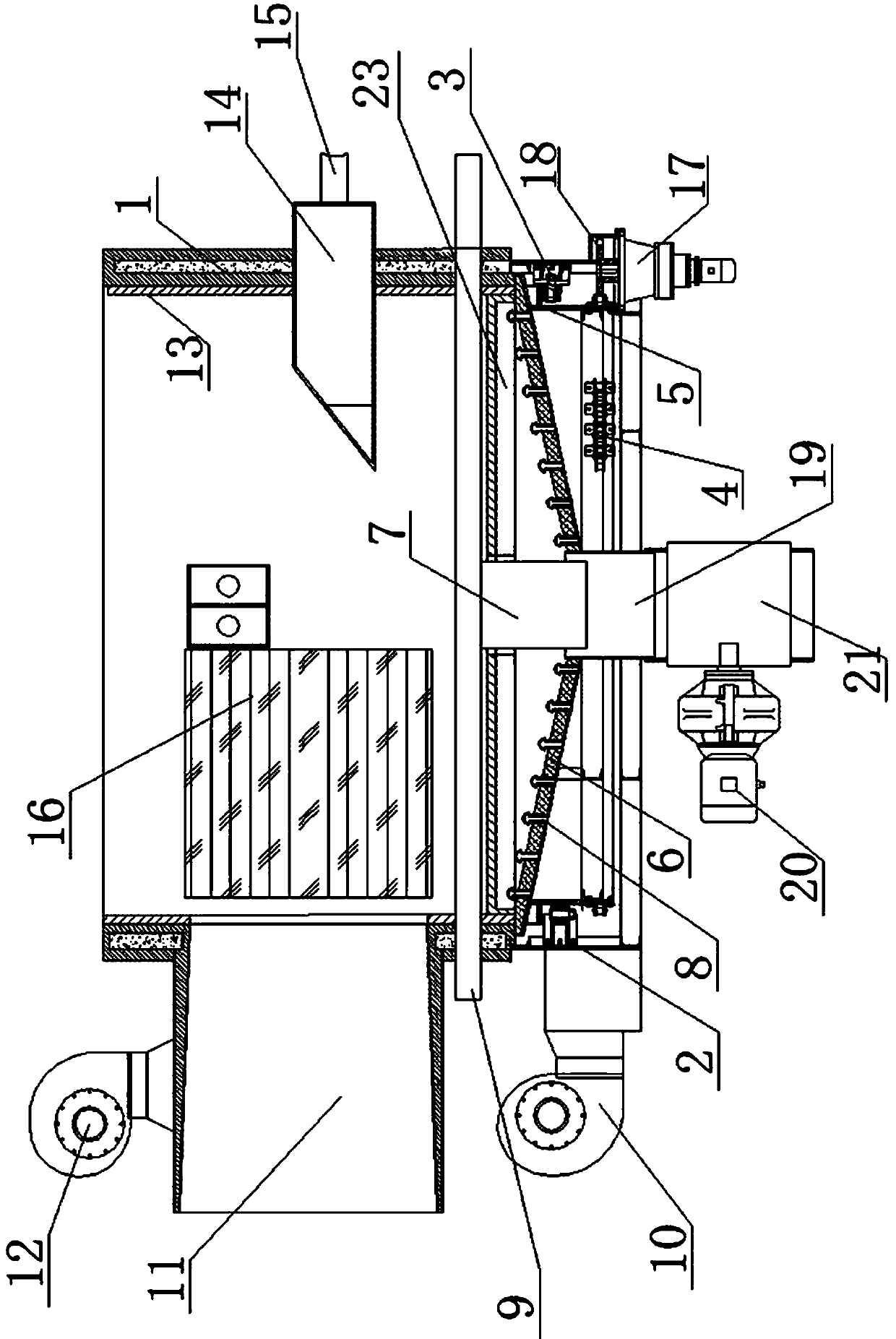

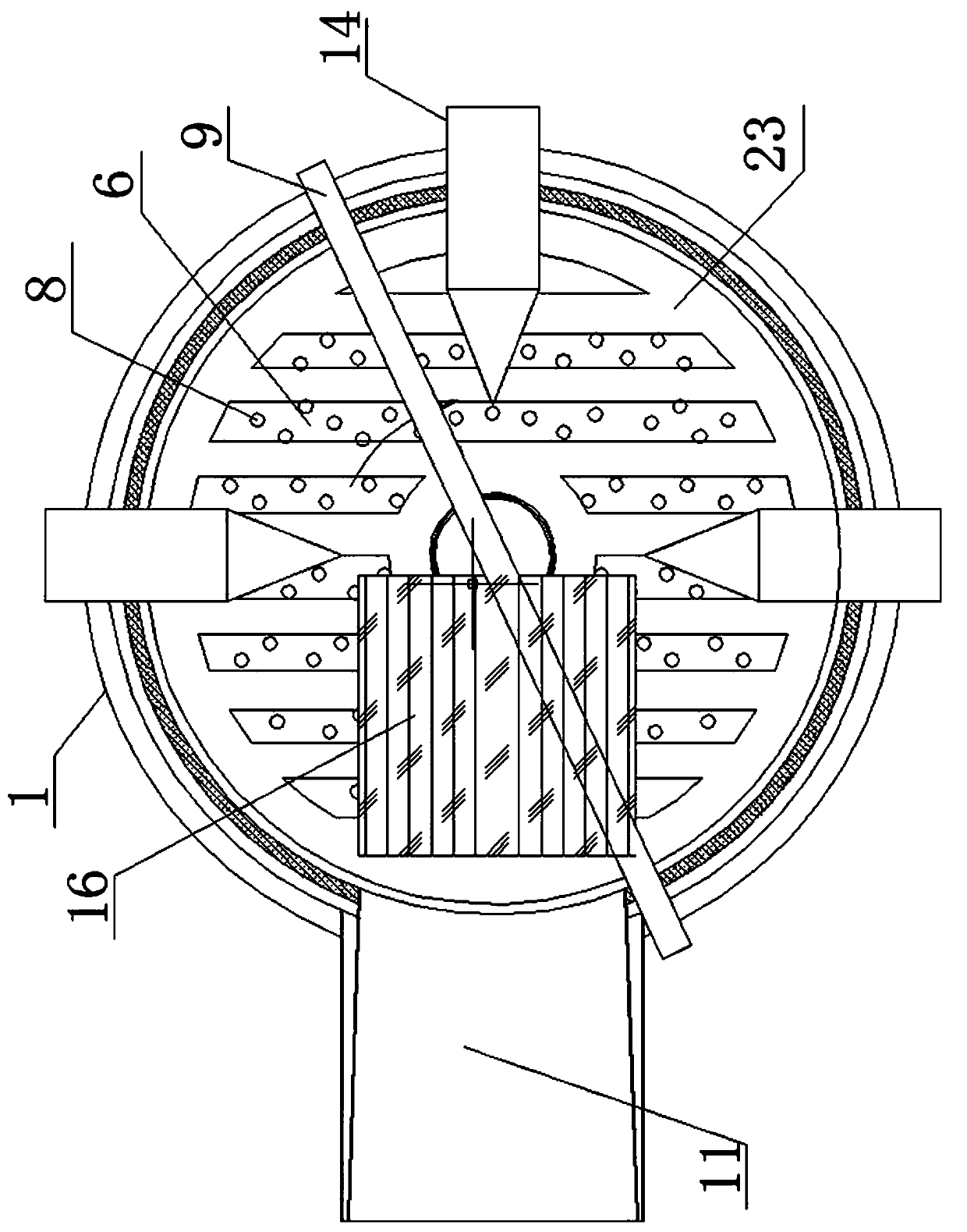

[0021] like Figure 1-4 As shown, a straw boiler capable of removing coking inside the furnace body includes a boiler, a boiler heat exchanger 22, an air blower 10, a feed port 11, an air wall blower 12, an ash removal port 19, and an air shutoff drive motor 20 And the air shutoff device 21, the boiler heat exchanger 22 is installed on the top of the boiler, the water pipe of the boiler heat exchanger 22 is connected with the external pipeline that needs to be heated, the smoke exhaust pipeline is arranged on the top of the boiler heat exchanger 22, and the bottom of the boiler is connected with the ash removal port 19 is connected, and the bottom of the ash removal port 19 is connected to the relevant air device 21, and the air shutoff device 21 is driven by the air shutoff device drive motor 20, and the air supply blower 10 for supplying air to the inside is provided on the bottom side wall of the boiler, and a useful air blower 10 is provided on the boiler side wall. In the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com