A macro-micro composite platform driven by servo motor and piezoelectric ceramics

A piezoelectric ceramic drive and servo motor technology, which is applied in the direction of machine/support, supporting machine, mechanical equipment, etc., can solve the problem of unused macro-micro composite, reaching tens of microns, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

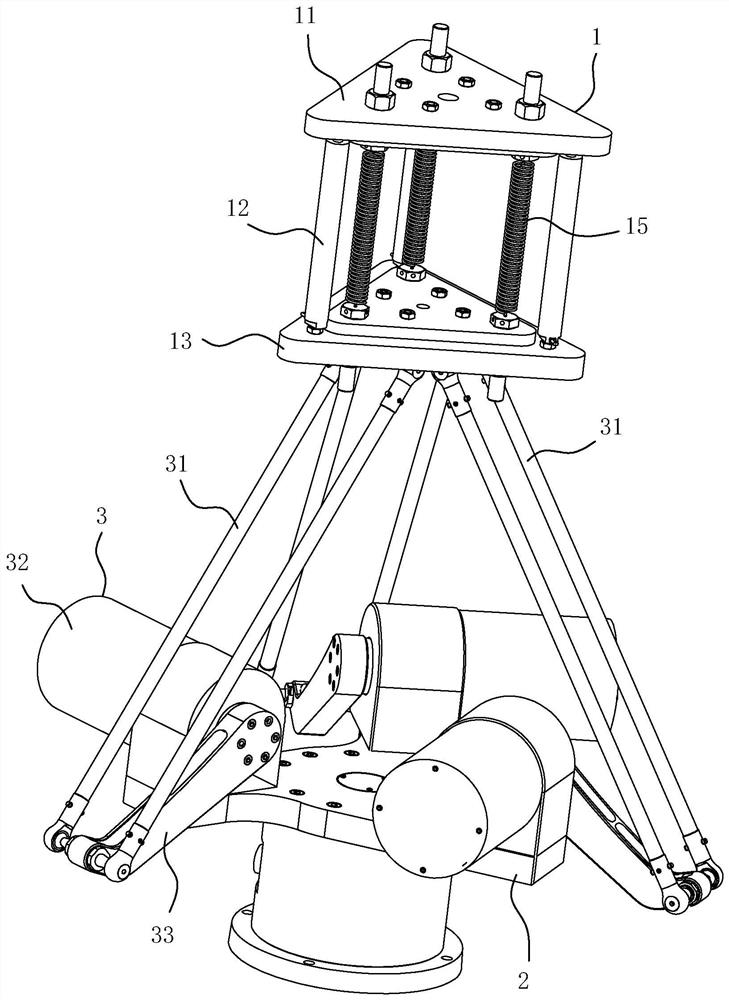

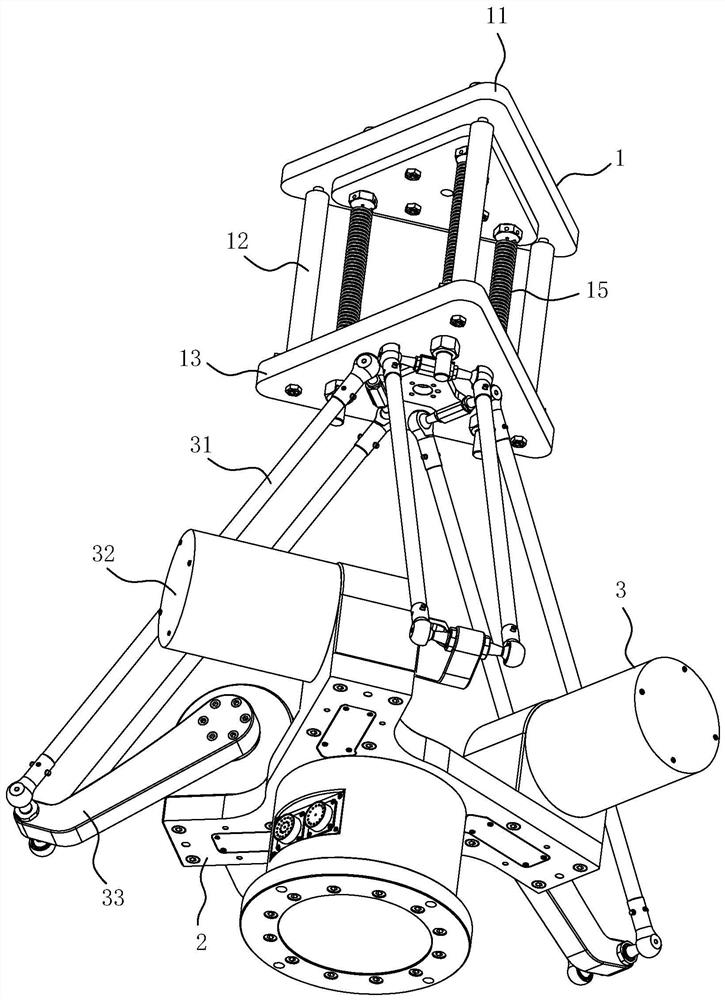

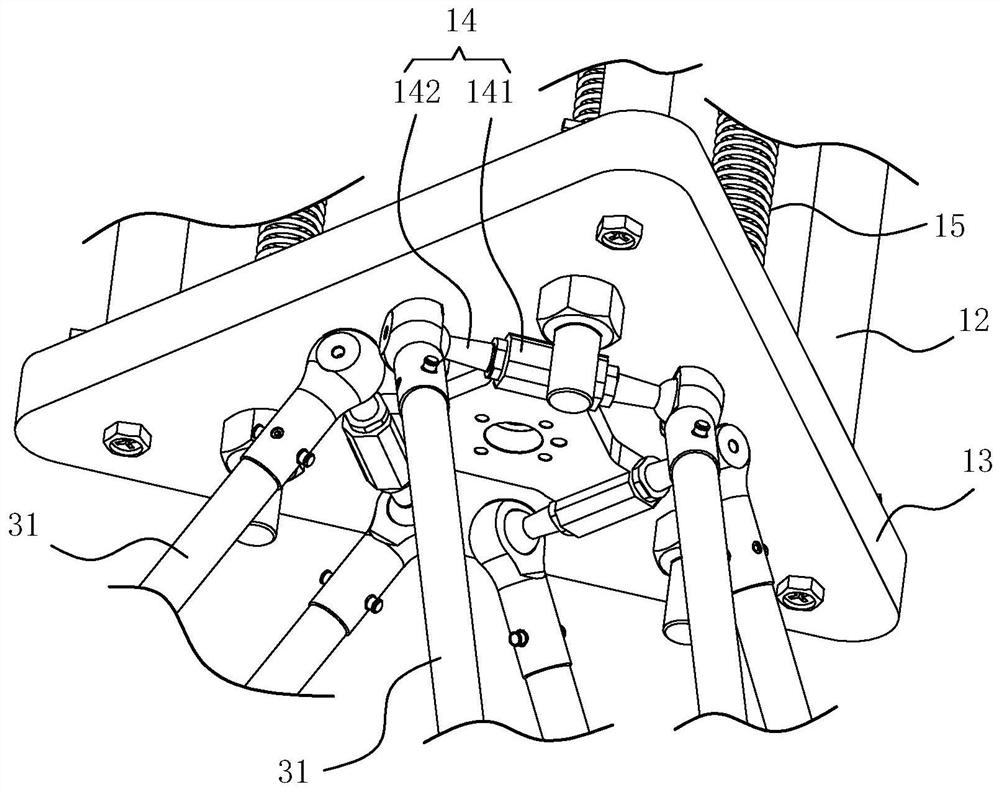

[0023] Such as figure 1 and Figure 4 As shown in , an embodiment of the present invention provides a macro-micro composite platform driven by a servo motor 3 and piezoelectric ceramics, which includes a micro-platform 1 , a base 2 and three servo motors 3 . Described micro-platform 1 comprises upper plate 11, three piezoelectric actuators 12 and lower plate 13, and described piezoelectric actuator 12 is piezoelectric ceramic actuator, and the bottom end of described piezoelectric actuator 12 passes through Threaded fasteners are fixed on the lower plate 13, and the connection positions between the piezoelectric actuator 12 and the lower plate 13 are distributed in a triangle, and the telescopic head at the top of the piezoelectric actuator 12 is connected to the The bottom surface of the upper block 11 is connected, and the connection positions of the piezoelectric actuator 12 and the upper block 11 are distributed in a triangle. The piezoelectric actuator 12 controls the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com