Safety locking device and method for explosive mixed loading vehicle

A technology for safe locking and mixing trucks, applied to explosives, fixtures, explosives processing equipment, etc., can solve the problems of loose side screw device, wear of side screw device, laborious and laborious manual operation, etc., so as to achieve easy access. And the effect of placing the side screw device, improving the locking strength and preventing loosening and falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the technical solutions of the present invention clearer and clearer for those skilled in the art, the present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

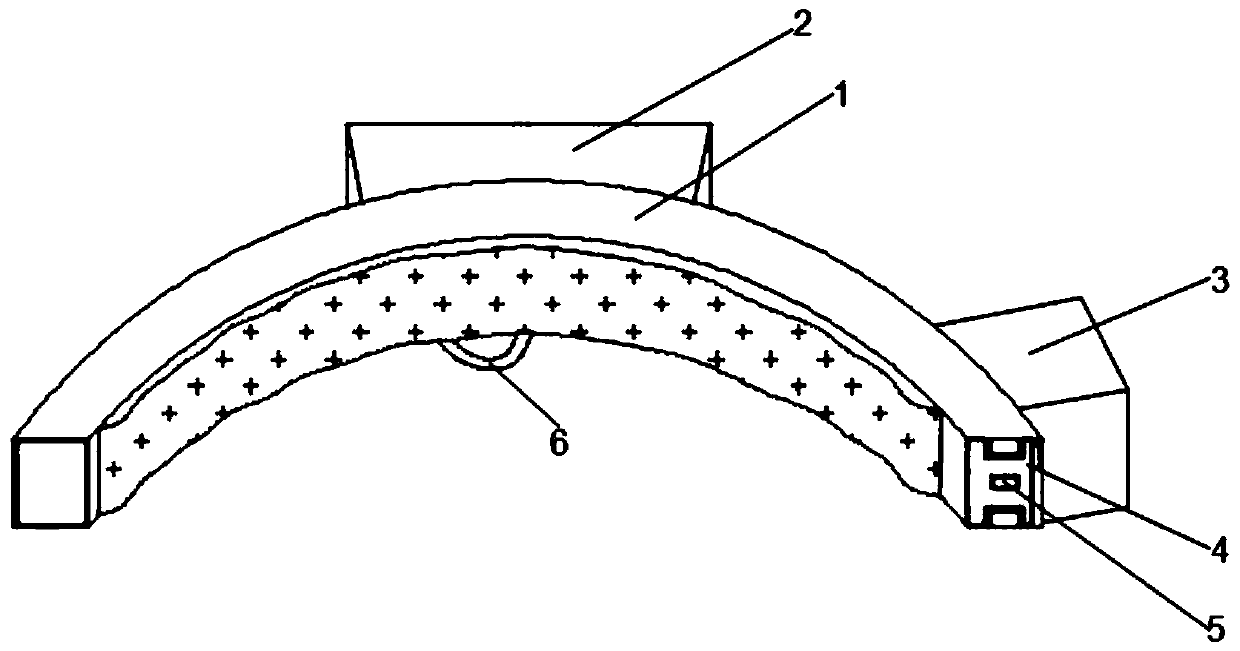

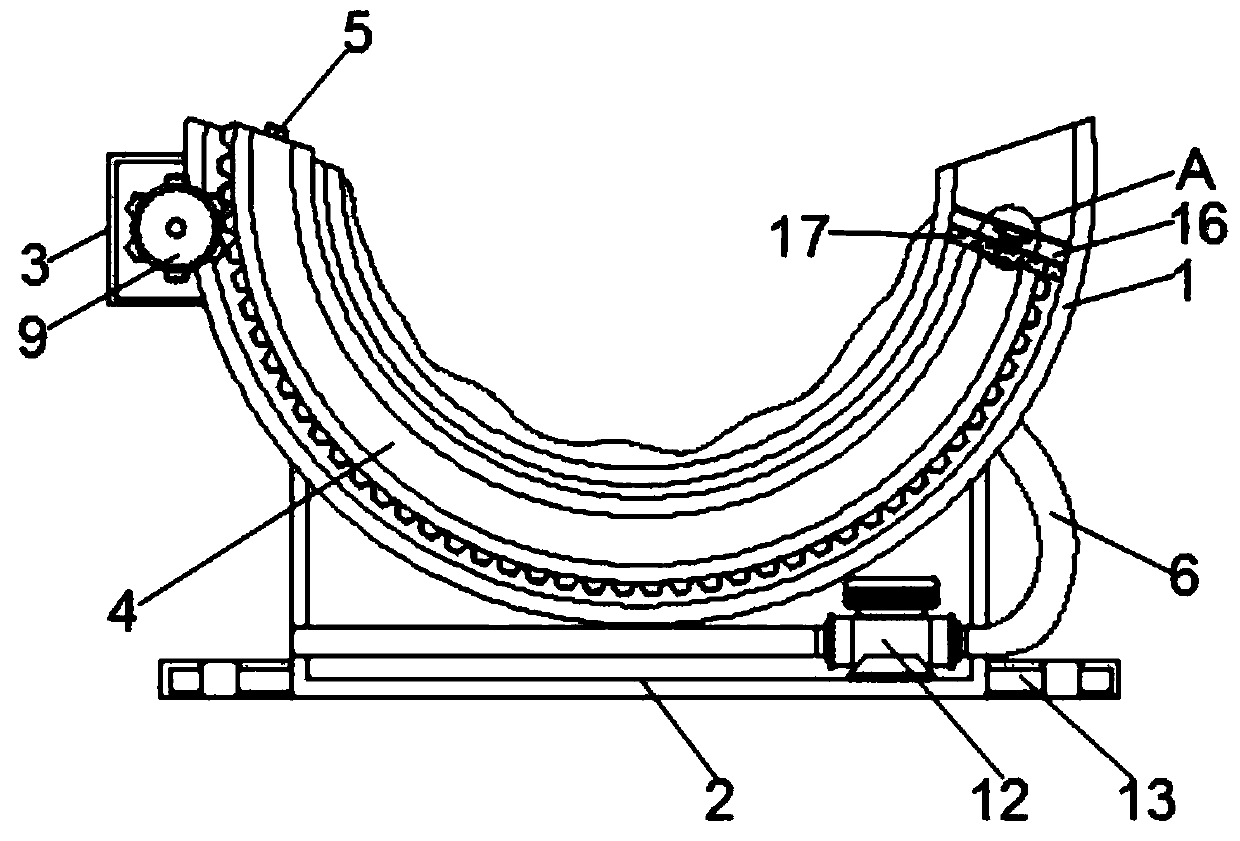

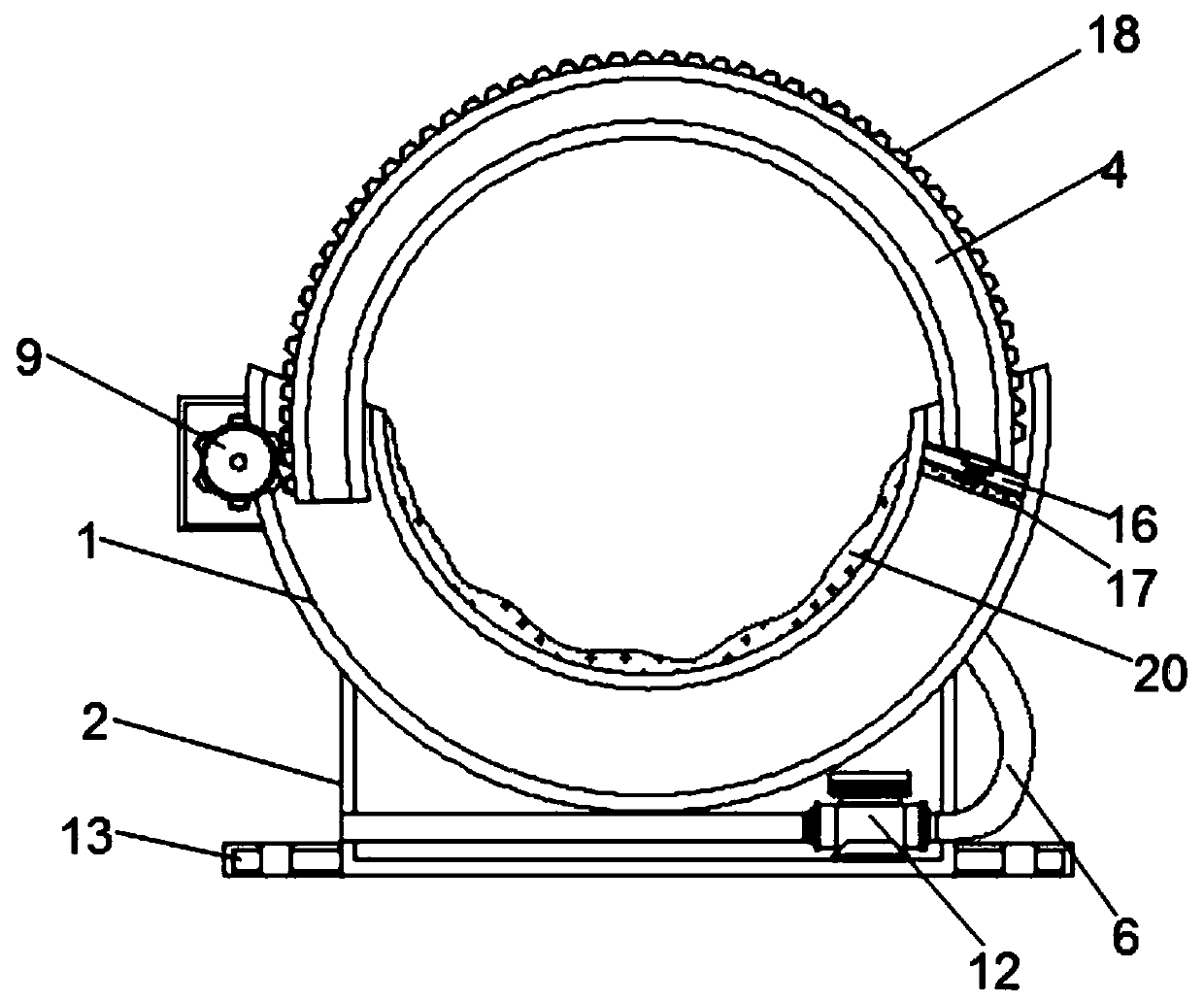

[0034] Such as Figure 1-Figure 6 As shown, the safety locking device for an explosive mixed loading vehicle provided by this embodiment includes a lock shell 1 and a lock tongue 4 arranged inside the lock shell 1. A tooth 18 is provided on one side of the lock tongue 4, and the outer side of the lock shell 1 A drive cavity 3 and a fixed seat 2 are provided. The drive cavity 3 is provided with a motor 21. The output end of the motor 21 is equipped with a rotating shaft 22. One end of the rotating shaft 22 is equipped with a first bevel gear 23. There is a second bevel gear 25 that cooperates with the first bevel gear 23. The inner side of the second bevel gear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com