Heating device used for glass tempering

A heating device and glass tempering technology, applied in the direction of glass tempering, glass manufacturing equipment, glass transportation equipment, etc., can solve the problems of glass damage, increase in tempering strength, restrictions, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

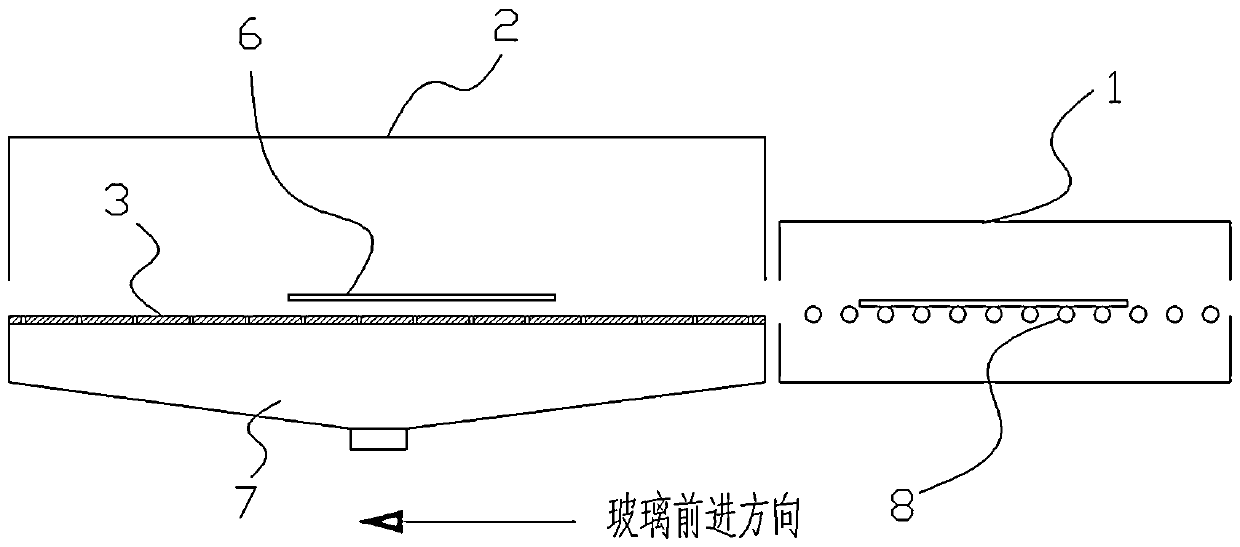

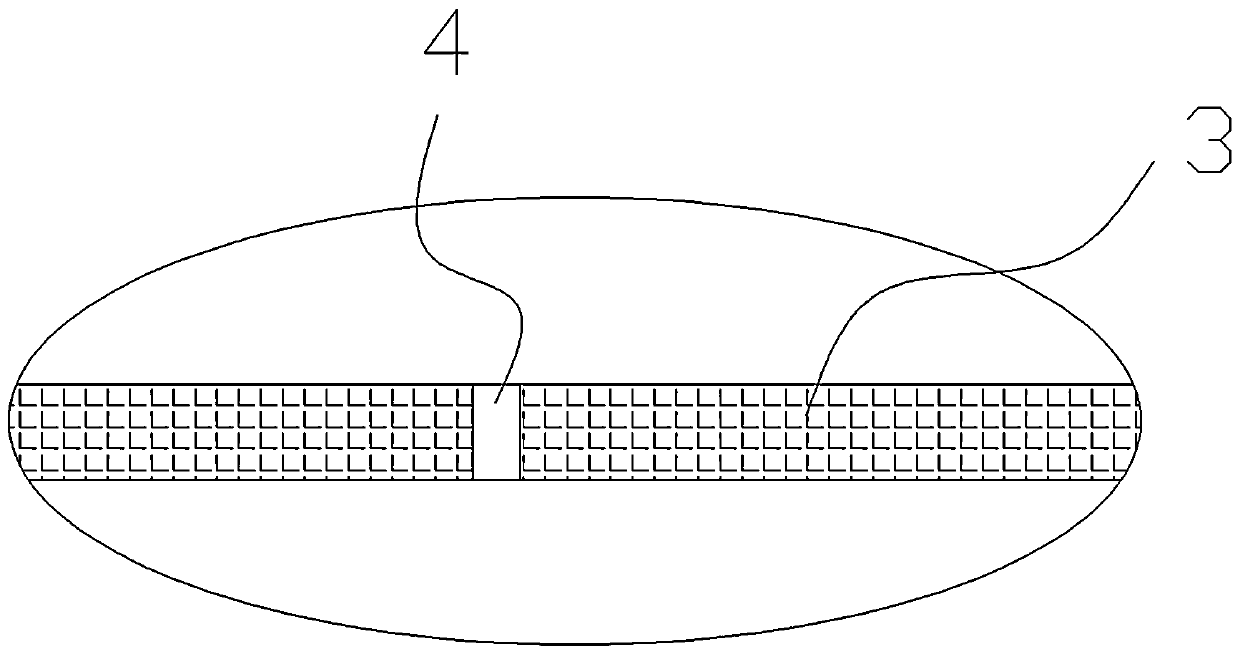

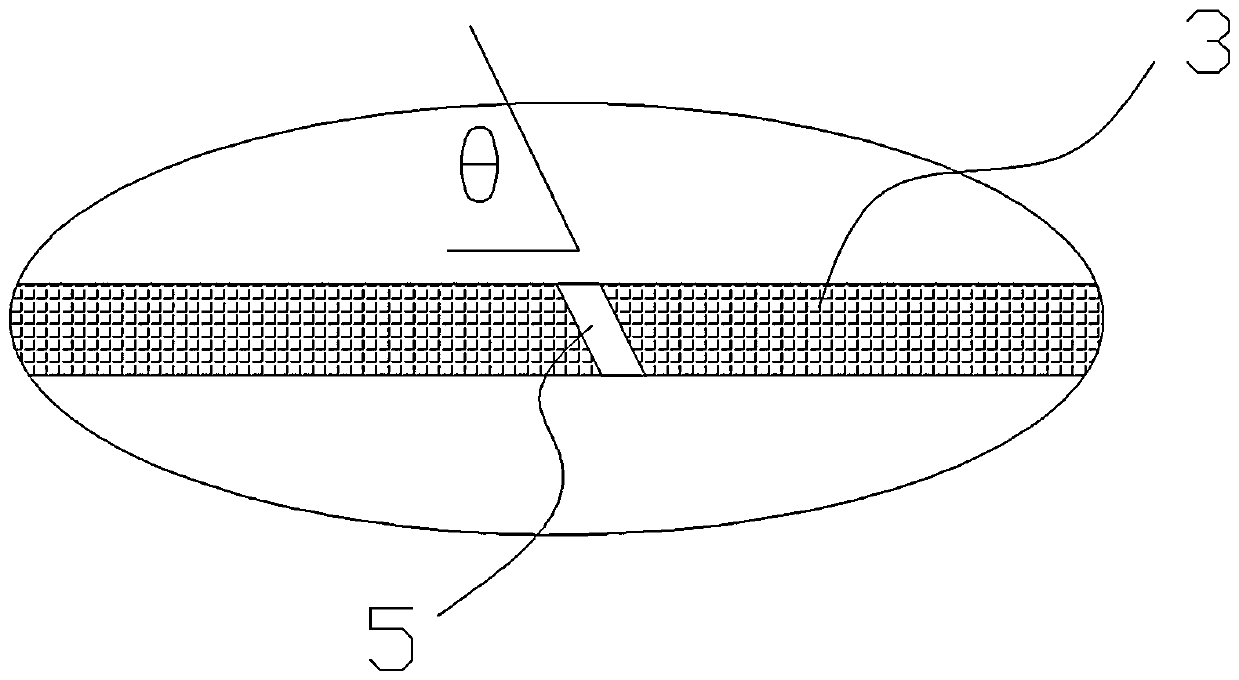

[0019] combine Figure 1~3 As shown, the present invention provides a heating device for glass tempering, which includes a roller furnace 1 and an air flotation furnace 2, the roller furnace 1 and the air flotation furnace 2 are arranged adjacent to each other, and the outlet of the roller furnace 1 It is connected to the entrance of the air flotation furnace 2; the air flotation furnace 2 is provided with an air flotation platform 3, and the air flotation platform 3 is respectively provided with a group of straight injection holes 4 and oblique injection holes 5, and the straight injection holes 4 are vertically upward. The oblique spray hole 5 is inclined upward toward the glass advancing direction. Preferably, the angle θ between the oblique spray hole 5 and the horizontal plane is 80-89°. The diameter of the oblique spray hole is the same as that of the straight spray hole.

[0020] combine Figure 4 and Figure 5 As shown, the oblique spray holes 5 include two rows, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com