Novel high-efficiency reel uncoiling machine and uncoiling method thereof

A reel unwinding machine, high-efficiency technology, applied in the direction of winding strips, packaging, thin material processing, etc., can solve the problems of unqualified pin standing, tube bullet flying, product loss, etc., to reduce the product loss rate , The effect of low loss rate and reduction of processing material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

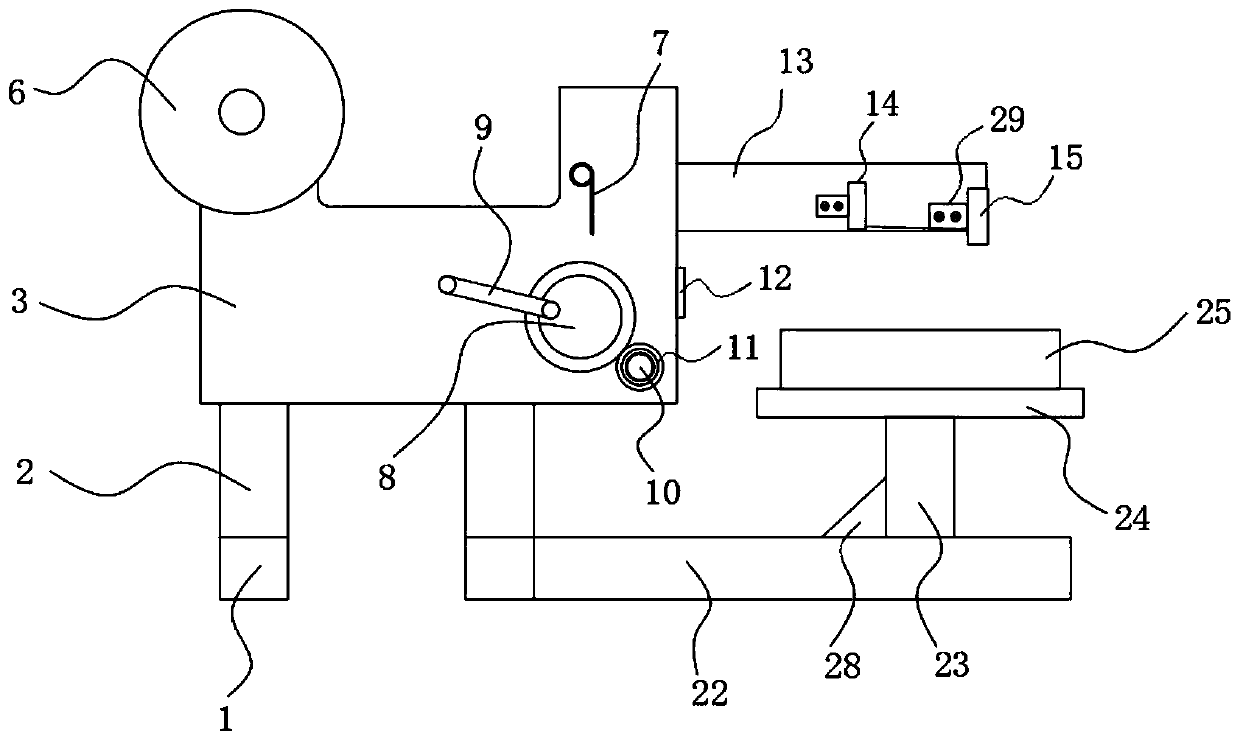

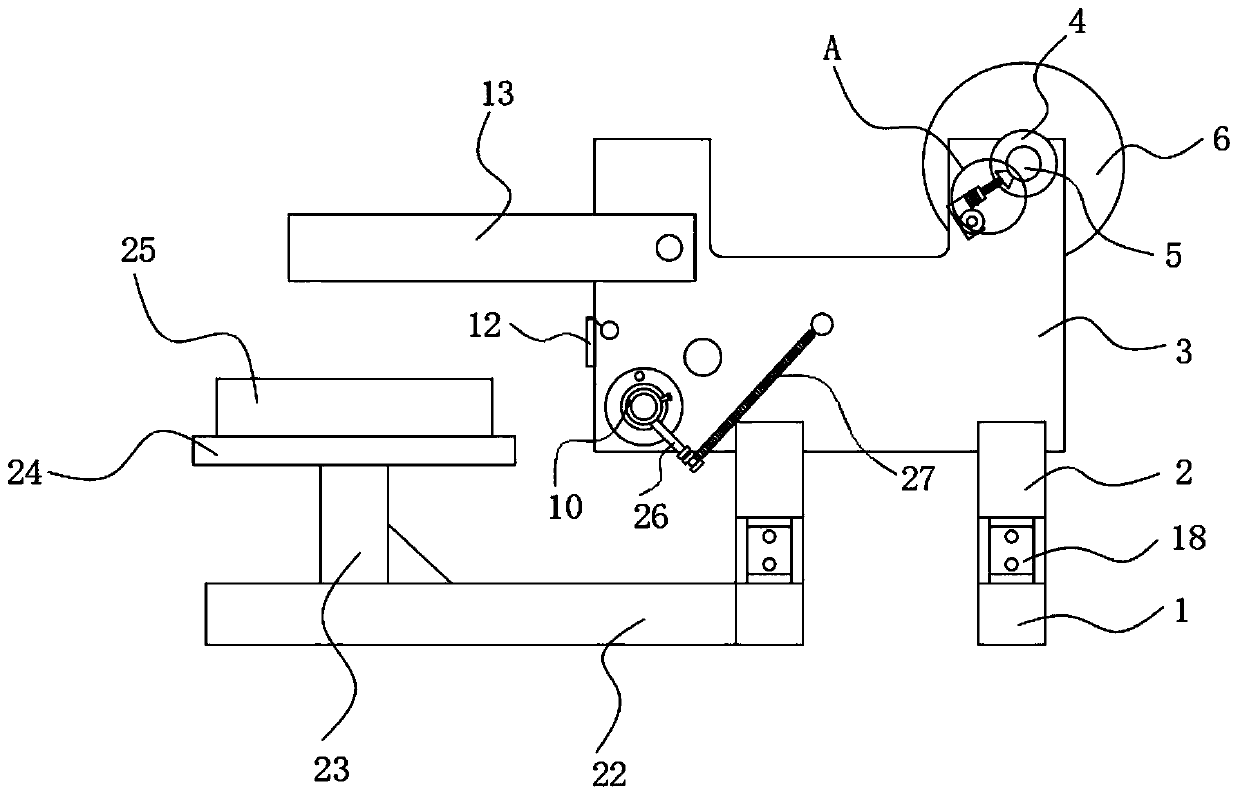

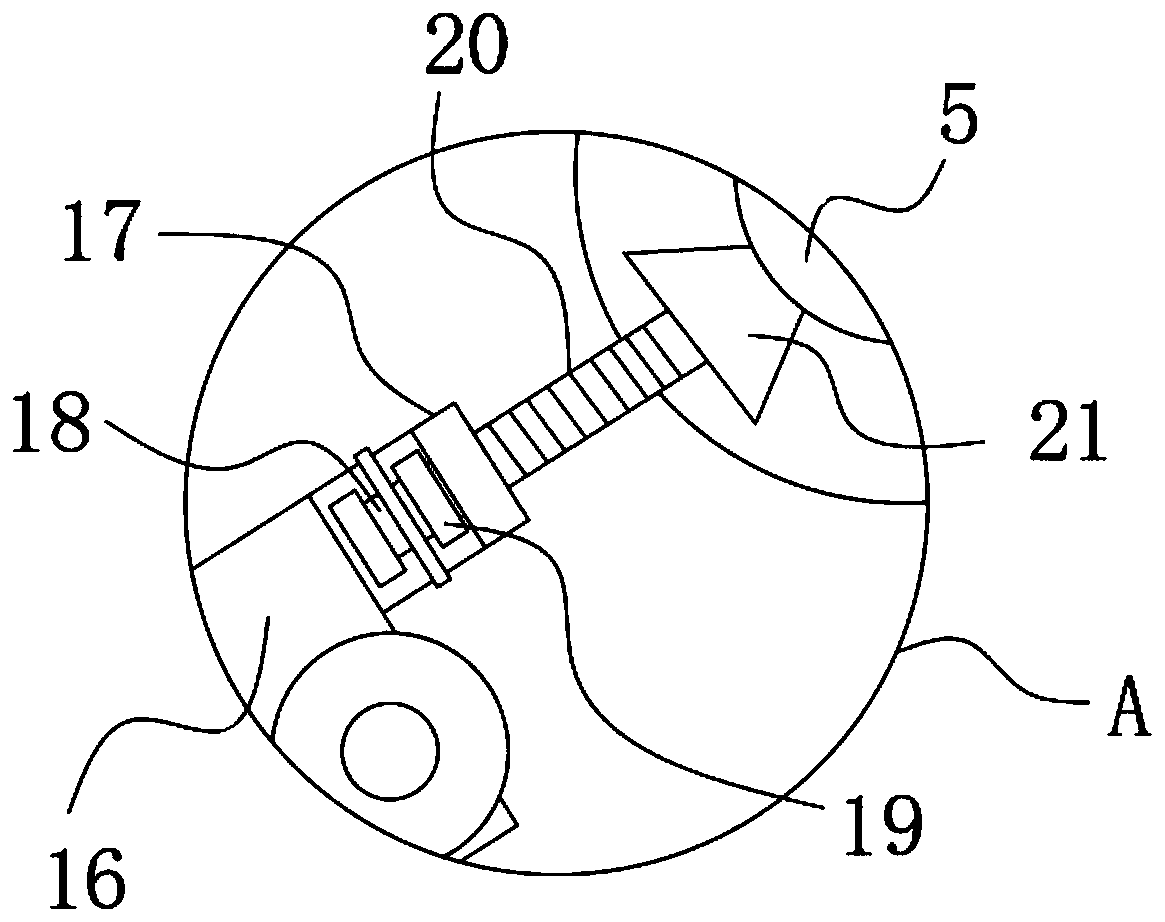

[0032] Such as Figure 1-6 As shown, the embodiment of the present invention provides a new high-efficiency reel unwinding machine, including a first base 1, the number of the first base 1 is two, and the upper surfaces of the two first bases 1 are provided with first mounting columns 2. The outer side walls of the two first installation columns 2 and the positions close to the top are fixedly connected with the installation plate 3, the left side of the installation plate 3 is fixedly installed with the fixed block 4, and the back of the installation plate 3 is close to the fixed block 4. The position is provided with an adjustment mechanism, the inside of the fixed block 4 is rotatably connected with a first rotating shaft 5, the end of the first rotating shaft 5 penetrates the side wall of the mounting plate 3 and extends to its front side, the outer surface of the first rotating shaft 5 is located on the mounting plate The front of the plate 3 is sleeved with a reel 6, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com