Rail car equipment based on automatic stereoscopic warehouse

A technology of three-dimensional warehouses and railcars, which is applied in the field of auxiliary mobile equipment for three-dimensional warehouses. It can solve the problems of complex use, poor operation convenience, and cumbersome picking and placing of containers, so as to prevent unstable movement, improve mobile stability, and prevent container damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

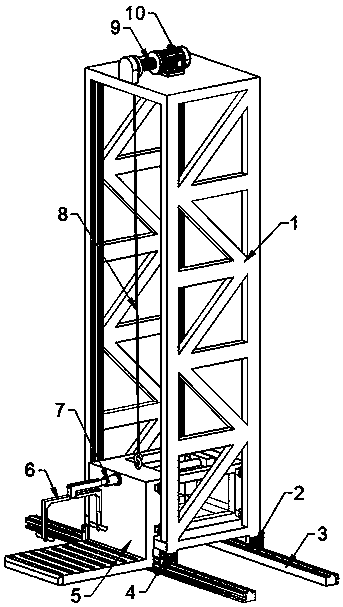

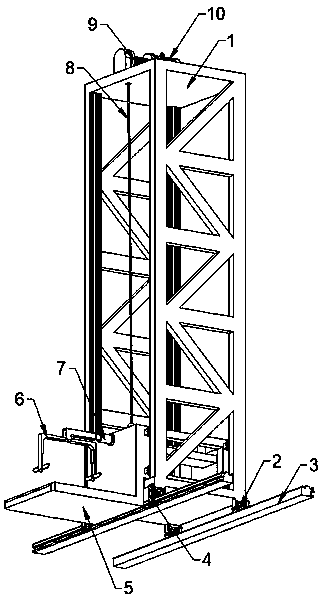

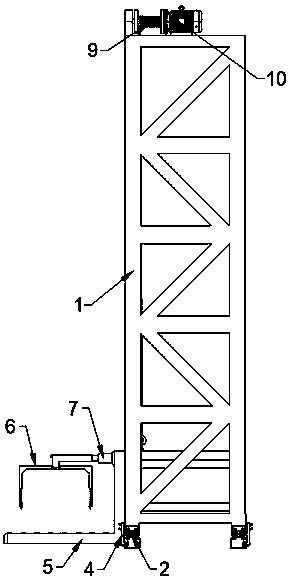

[0039] as attached figure 1 to attach Figure 9Shown:

[0040] The present invention provides a rail car equipment based on an automated three-dimensional warehouse, including: a lifting mobile frame 1, a rail moving wheel 2, a moving track 3, a limit chute 301, a limit locking device 4, a locking wheel 401, a lift Device 5, limit track wheel 501, cargo placement platform 502, pick-up device 6, push plate 601, one-character cursor light 602, shelf fixing column 603, pick-up grab 604, push hydraulic cylinder 7, lift wire rope 8, roll The wire reel 9 and the lifting motor 10; the bottom side of the lifting mobile frame 1 is symmetrically provided with four track moving wheels 2, and the lifting mobile frame 1 is installed on the top side end surface of the moving track 3 through the rolling limit of the four track moving wheels 2 On the outer end side wall of the rail moving wheel 2, the limit locking device 4 is fixedly fixed with bolts; the inside of the frame body of the li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com